7 Wastes

The 7 wastes are Taiichi Ohno’s categorization of the seven major wastes typically found in mass production:

- Overproduction: Producing ahead of what’s actually needed by the next process or customer. The worst form of waste because it contributes to the other six.

- Waiting: Operators standing idle as machines cycle, equipment fails, needed parts fail to arrive, etc.

- Conveyance: Moving parts and products unnecessarily, such as from a processing step to a warehouse to a subsequent processing step when the second step instead could be located immediately adjacent to the first step.

- Processing: Performing unnecessary or incorrect processing, typically from poor tool or product design.

- Inventory: Having more than the minimum stocks necessary for a precisely controlled pull system.

- Motion: Operators making movements that are straining or unnecessary, such as looking for parts, tools, documents, etc.

- Correction: Inspection, rework, and scrap.

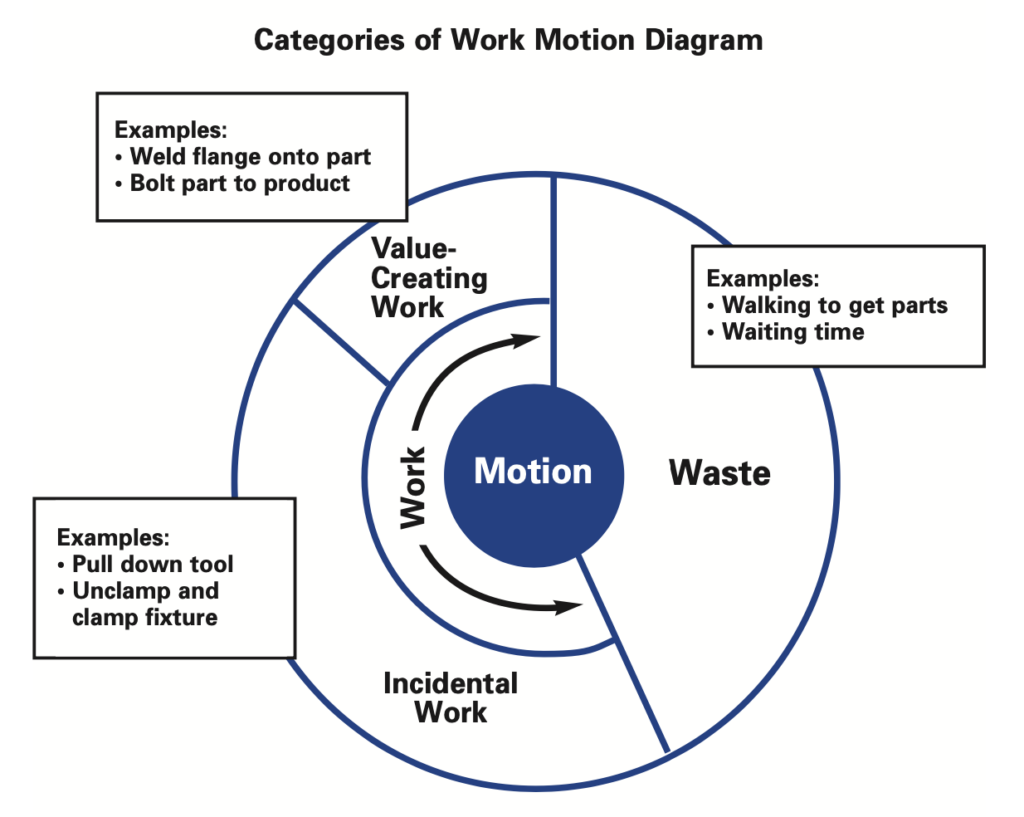

In order to see waste, it’s important to first understand how to see work. There are two categories of work:

- Value-Creating Work — movements directly necessary for making products, such as welding, drilling, and painting.

- Incidental Work — motions that operators must perform to make products but that do not create value from the standpoint of the customer, such as reaching for a tool or clamping a fixture.

- Waste — motions that create no value and can be eliminated, such as walking to get parts or tools that could be positioned within reach.

While observing work waste manifests in an operator’s mind and body. For instance, if an operator must search for parts or recall instruction, then there is waste in the flow of information to the operator. Similarly, if an operator must bend, reach, or walk to complete a job, there is waste that should be targeted for elimination. This not only improves productivity but makes the job safer and easier for the operator.

7 Wastes Video Series

Overproduction

Waiting

Conveyance

Excess Processing

Excess Inventory

Excess Motion

Correction

Additional Resources on the 7 Wastes

Article

The Seven Types of Waste

Synonyms:

7 Wastes