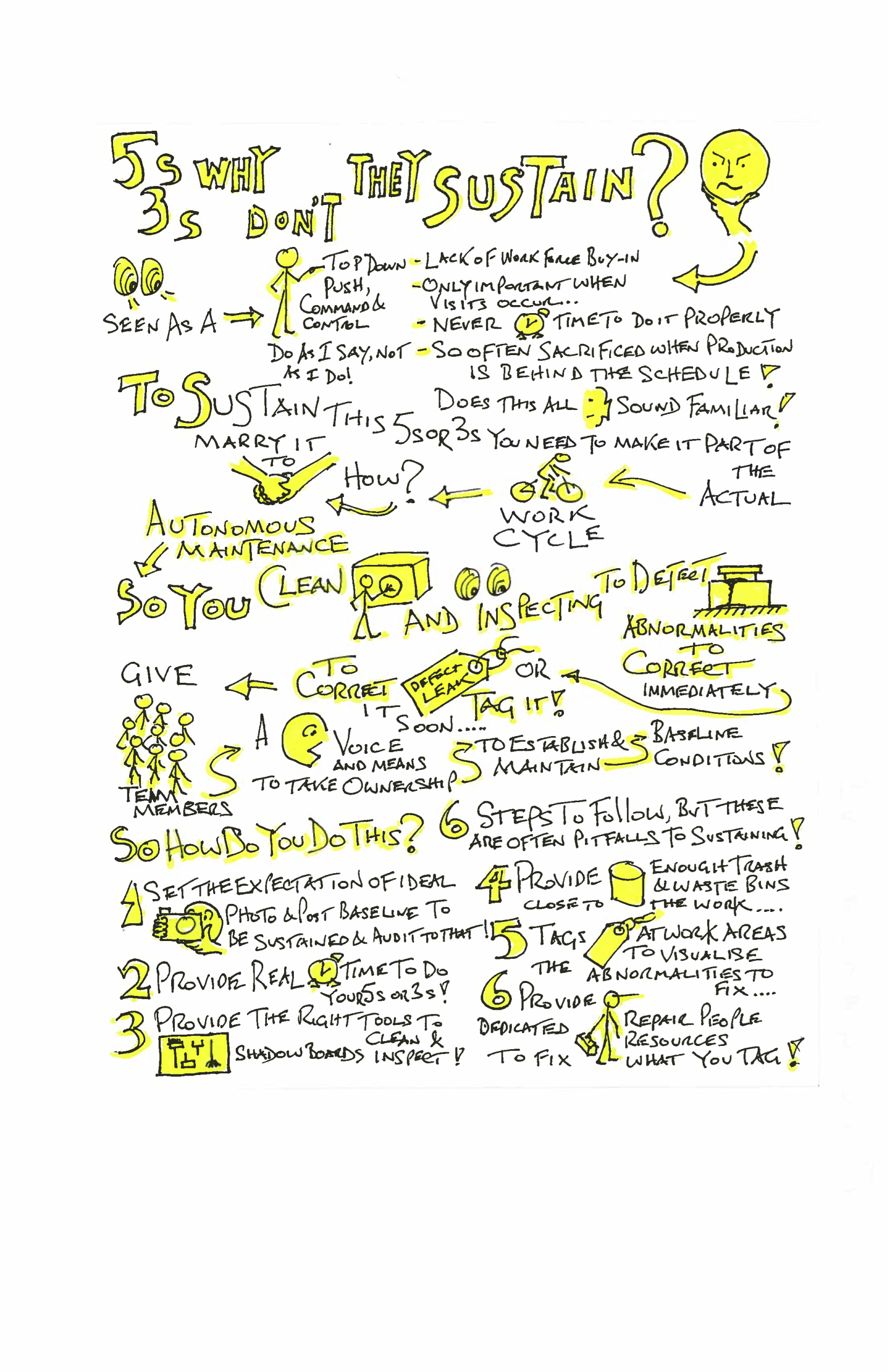

5S (often thought of as housekeeping) is an essential practice for most lean thinkers that, unfortunately, we take for granted over time. Until, that is, events such as a customer or VIP visit forces us to suddenly re-establish housekeeping methods. All of which raises the question:

Why can’t organizations make the whole aspect of 5S or even the simplified 3S approach stick and be sustained? How can we ingrain this approach as simply the way we do things?

Everyone must view cleanliness writ large as a pre-condition for doing your job properly.Housekeeping comprises an essential part of the actual work of doing your job. Over years of lean work I have learned that mindfulness about how you do what you do should never be viewed as a separate activity. Everyone must view cleanliness writ large as a pre-condition for doing your job properly. Understanding where, when, and how things get done needs to be a condition of leaving the work place at the end of your shift or day. Activity creating a safe and healthy work environment for not just you but those around you as well must be an explicit and primary shared goal.

So why does this target become obscured so often? And how can we sustain this?

I have found that the fundamentals of housekeeping become truly sustainable when they are married to the core aspects of autonomous maintenance. People should frame housekeeping as a means of establishing and maintaining baseline area and equipment conditions. It identifies and detects normal from abnormal conditions, helping to fix or correct issues that can prevent us from safely and effectively doing the work to the required predefined standards. Autonomous maintenance, married to 5S, guides people to detect and fix ‘small issues’ before they become catastrophic breakdown moments (such as knocking out a shift if not a day or more of production.)

How Do I Make this Work?

First thing to do is to pair up the actual cleaning with inspection (detecting). Deeply examine what you are cleaning, scanning for anything that looks abnormal, loose, broken, leaking, out of place. Combine your eyes with your other senses: touch (can you feel heat, vibration), smell (burnt, odd smells). Can you hear air escaping from a connector or fitting?

These senses will highlight any abnormality you must address. Understanding where, when, and how things get done needs to be a condition of leaving the work place at the end of your shift or day. After cleaning (which might include wiping, sweeping, brushing, vacuuming up debris), you can now permanently Understanding where, when, and how things get done needs to be a condition of leaving the work place at the end of your shift or day. correct the abnormality you have detected. Correcting the abnormality you have detected should now be a priority to follow up on. At a very minimum, you should always tag what is found (using bright colored tags) if you can’t fix the issue on the spot. Tagging abnormalities is a hard mechanism preventing team members from handing off problems that can potentially hinder them from doing the work safely and effectively. It ensures that the issue is flagged for action, avoiding the dreaded ‘workarounds’ that result in waste—which show up as anything from lost time to defects experienced by the customer.

Tags identify what must be fixed at the first available opportunity by another better trained or equipped team member. Tags expose and highlight risks in the workplace: suboptimal conditions that can impede production. Tags are a productive way of bringing problems to light, and spur useful conversations about removing waste.

Focusing everyone on this “housekeeping” is one of the most powerful mechanisms for empowering team members and driving sustainment of any lean effort at the lowest possible level. It’s a practical vehicle exposing problems that must be addressed. And it is the secret to SUSTAINING a culture of 5S (or 3S), creating a feedback loop that fixes abnormalities.

Here are six quick takeaways to consider:

- Set the Ideal expectation or the baseline minimum condition with pictures of what you expect to see as clear reference points, so there is no misunderstanding.

- Provide the real TIME to get these actual tasks done! Don’t steal that time from the team members at the risk of deteriorating working and equipment conditions.

- Provide team members with the right cleaning tools to do the job in the right quantities, and ensure a replenishment of these as required to maintain the standards.

- Make sure there are enough trash containers, which are close to the work, emptied frequently, and replaced as needed.

- Provide adequate tags to apply to equipment for repair, and replenish these as used.

- Provide dedicated maintenance resources to check and review tags, to schedule or effect immediate repairs or replacement.

I hope you will make housekeeping an ingrained habit as a means of respecting your team members and developing a culture of improvement.