I’m a career automotive guy, an engineer turned manager who started out in quality and did the circuit in manufacturing. My hair turned to grey faster than I planned and I found myself moving full circle back into quality and continuous improvement in my present role as a VP in a global enterprise.

My hobby and passion today is Lean. I’ve been actively pushing down the lean route since 2006 when I transitioned from plant quality manager into manufacturing as KAUTEX Textron’s TPM regional leader and then CI leader. Working in these positions I learned more and more about the Toyota Production System, not just tools and techniques, but what made it different in terms of culture, mindset, and behaviors. The more I’ve learned, the more I’ve come to like teaching people about lean thinking, and I get pretty animated talking about it. This animated quality seems to help drive my point home in conversations with team members.

So after a while I began thinking, how can I effectively communicate lean ideas having to do with culture so that behaviors, techniques, and tools stick? What makes for a powerful conversation with my team? For too long corporate culture had been “death by PowerPoint.” 60 slides into a presentation, I’d think, “Get me out of here!” Who cared what the message was! What a waste of time.

I wondered, How can I communicate my message to organizations that don’t think or act anything like Toyota? When I’m sharing information, what is the bare essence of my message? Let’s get right to the substance! I thought, Try drawing just a simple sketch… make people think so they have to respond with their own interpretation of what I’m drawing.

I continued to develop this approach to communication (images and graphic text) in my work with BAMA (Bluegrass Automotive Manufacturers Association, suppliers of Toyota North America). In their workshops, they also emphasized the importance of visual images, showing how powerful they can be if the message is packaged right. From here my approach to communicating visually was coupled permanently with enthusiasm for lean thinking.

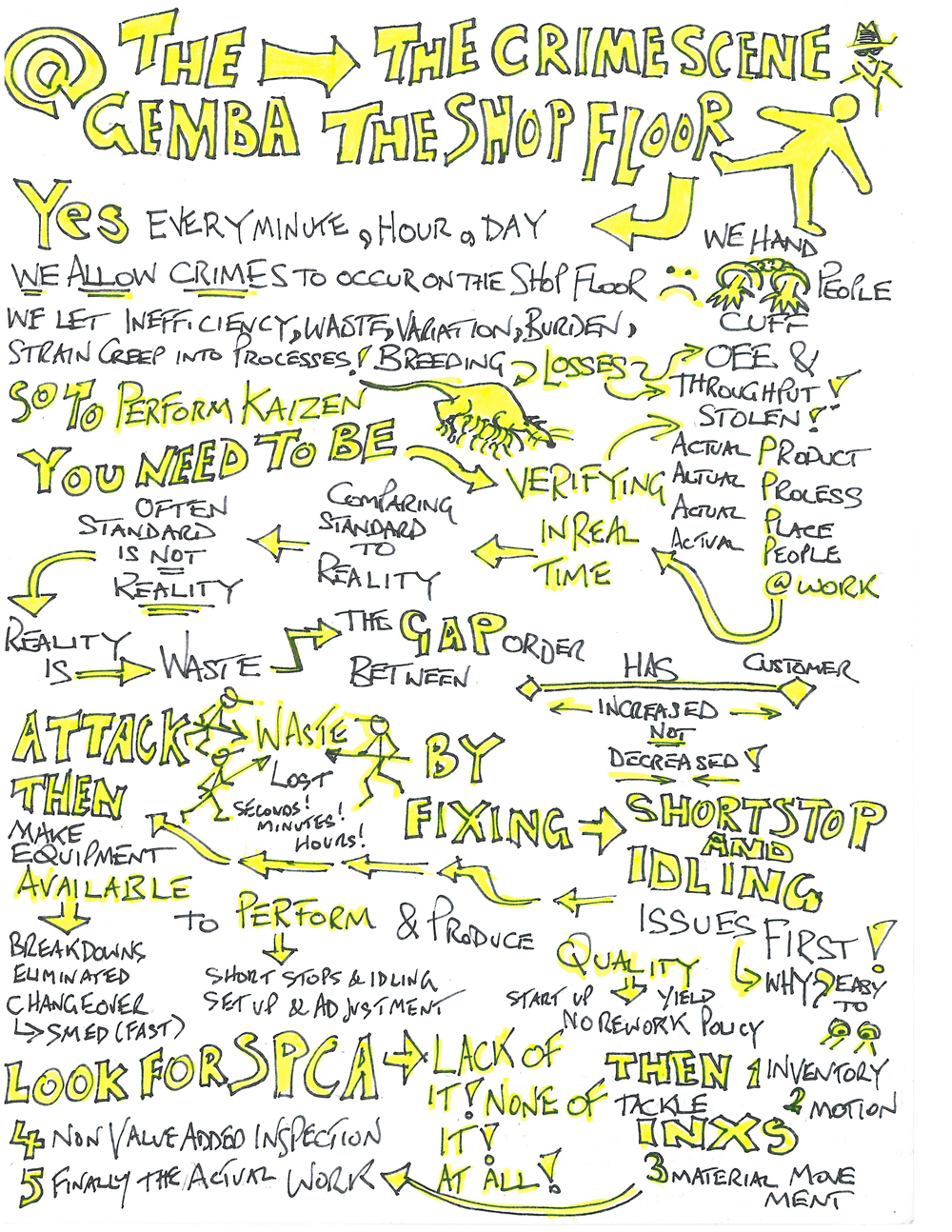

This image below is one I’ve used with frontline workers in an automotive plant:

Going to the gemba and playing detective is critical to eliminating waste and fostering lean thinking in yourself and others. Look at the image above and follow the story, interpret the images. What do you see? Take the image to your shopfloor. Can you see the holes, gaps, waste, burden, struggles, inconsistency I’ve seen so many places?

Or, draw your own images of what you see at the gemba and from that, think about what’s most important for you to communicate with your team. How will you communicate it?

Identify problems, draw them, and then start to fix them, one step at a time.