At LEI our mission is to “Make things better through lean thinking and practice.” Some of you remember it used to be “advancing lean thinking throughout the world,” but as the lean community has changed, it’s been increasingly important to us to be clear on what we’re really trying to do – and that’s make things better, whether that’s products and services, the way organizations function, or working conditions for employees.

Our vision is the same as it’s always been, to serve as a bridge between theory and practice and help society improve through lean thinking. How do we aim to do it?

- By supporting you, our community and customer, to make things better through lean thinking and practice (LT&P)

- Encourage more individuals and organizations to try LT&P

- Practice LT&P in all of our own activities

- Partner with other companies and organizations who share the same mission

- Create products and services that meet your needs by being interesting and most importantly, useful

How do we aim to do these things? To actually accomplish these goals? That’s where Hoshin comes in.

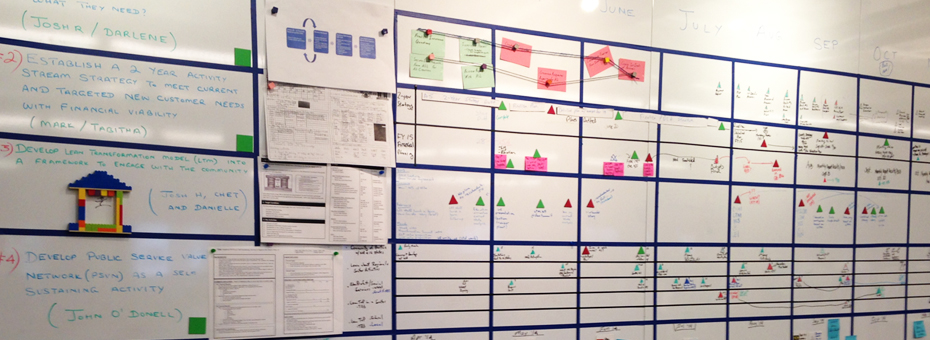

At LEI, we follow a Hoshin (Strategy Deployment) process to set our objectives. Near the end of each calendar year we reflect on what we accomplished the previous year, consider how we should challenge ourselves to better serve our customers and community members in the coming year, and reflect on our mission, vision, and strategic priorities. Then we set new goals. LEI has been working diligently to develop and execute a hoshin structure that brings out innovation of thought and process. As a small nonprofit, it’s taken us many cycles of PDCA to practice lean thinking ourselves and to closely connect our processes with our customer.

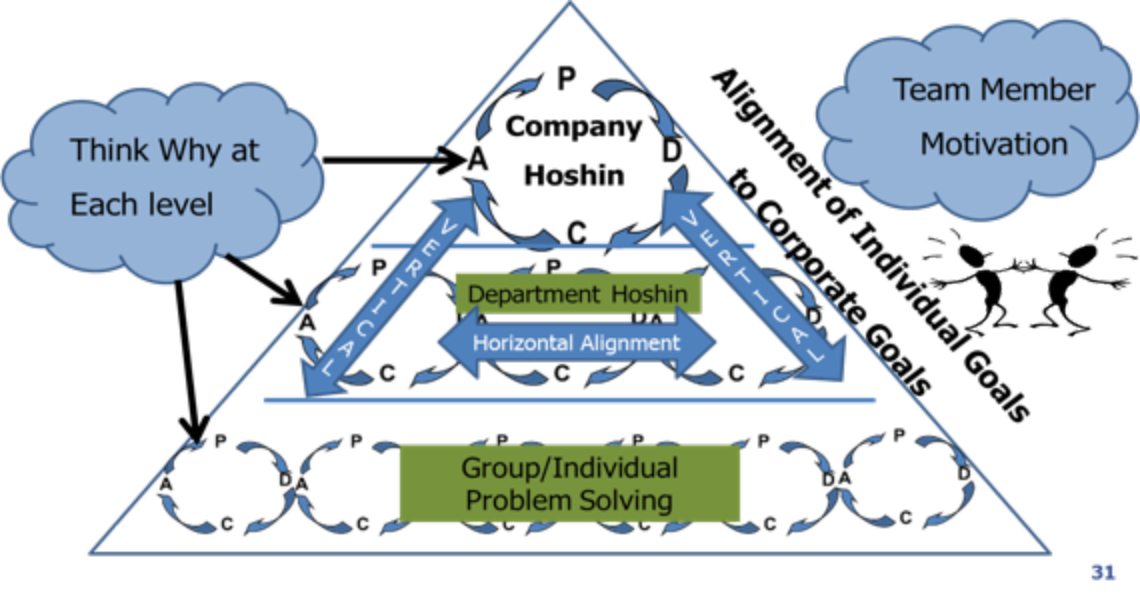

I personally spent many years in a large organization (Toyota) doing hoshin work to do exactly this. Whether you’re deploying hoshin in a small nonprofit or a huge organization, the struggles are the same. How do you create alignment across the organization? How do you get team members more actively engaged with the work? How do you encourage and create the conditions for a culture of continuous improvement, including daily PDCA? How do you do Hoshin deployment without overburdening your team members?

As leaders, how do we create a deployment structure that gets each team member to think about the customer and the “why” behind the problems he/she is trying to solve for the customer and for the organization? How do we motivate people to seek alignment with company objectives both horizontally and vertically? Whatever the work is, how do we support people in taking ownership of their work and how do we help people build their problem solving capability?

This graphic below is one I use to show the importance and thinking behind building vertical and horizontal alignment. Use this in your own organization if you’d like.

As the lean community has grown, our #1 hoshin item was to better define and understand you, LEI’s customer and community member. In the coming weeks, we’ll share reflection pieces on various LEI hoshin items – some of which have carried over into the next year.

In the meantime, let me know if you have questions about Hoshin or LEI and I’ll be happy to answer them in the comments.

Join Mark Reich for LEI’s Live Online Workshop: Hoshin Kanri Remotely: Aligning and Executing on Your Organizational Objectives.

Hoshin Kanri

Aligning and Executing on Your Organizational Objectives.

Can you explain futher about the “What, Why, and Goals” of Hoshin and how a facilitator (myself) can help an executive team (used to traditional strategic planning) understand how these are defined