Organizations should be focused on the long-term, but evidence demonstrates many process improvement projects are short-lived. Somewhere between 60-90% of business improvement projects fail to sustain their initial impact. See the case of the aerospace company in The Wall Street Journal and “Jumping on the Lean Bandwagon” in Industry Week.

As a lean coach and change agent who has supported improvements in more than 100 manufacturing and service companies as well as buying and transforming my own manufacturing organization, my experience is similar. I’ve spent the last few years experimenting with how to help organizations achieve sustainability. With most improvement projects, part of the problem has been that fundamental traits and behaviors are not altered to align with process improvements, which means old habits and attitudes quickly creep back in. Many lean leaders are much more comfortable implementing the technical and market-driven solutions and aspects of lean, only dealing with the social aspects (soft skills or cultural issues) as they become roadblocks. As many of us have begun a successful career based on technical expertise, it’s often unnatural to focus on soft skills. But in order for a lean transformation to be successful, both the hard skills (or technical issues) as well as the soft skills (social aspects) of lean must be addressed simultaneously from the beginning.

We have plenty of data now to show that the lack of sustainability often begins when team-driven improvements are not strongly linked to organizational goals. As a result, these efforts never receive the support, focus, and attention they need from leadership. Continuous follow-up is necessary to overcome ingrained behaviors and habits. Proper strategy deployment offers the best solution for prioritization and ultimately achieving sustainability, but often this “deployment” lacks the necessary engagement from senior leadership.

Don’t take my word of how well your strategy is deployed! If you feel your strategy is working, make random enquiries with five or ten associates from various levels and departments, asking what the company’s targets are and what actions they are personally taking in pursuit of those targets. Then draw your own conclusions. You might imagine, leaders are frequently surprised as to what they felt was clearly deployed and communicated and what was actually understood. When such a gap exists between perception and reality, then lean improvement projects feel like just another “flavor of the month” program.

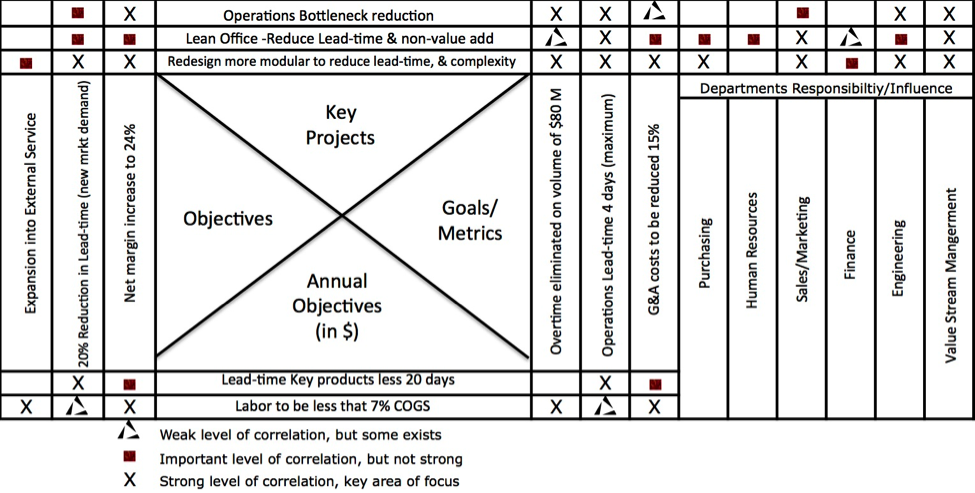

Therefore, the first critical step for lean leaders is a refocus on strategy deployment. This might mean enhancing some of the current and confusing “tick the box” methodologies like X-matrices with simple, more engaging methods. After top management determines 3-5 key focus areas, team leaders should work to identify programs and actions to confirm and reach targets. Be careful, often some departmental engagement gets overlooked as leadership or department heads themselves feel they don’t need to be involved in particular improvement efforts or don’t have control over particular organizational objectives.

A practical way to engage all levels in your annual strategy development is to use a simple matrix like that shown in figure 1. This facilitates a discussion at each intersection, where an objective (shown across the top) can be examined in relation to what actions a department can take to support it. This helps not only in identifying actions where there is control, but also fleshes out where the department can have “influence” (the various colored post-its distinguish control versus influence). Compare this to the X-matrix shown in figure 2, which in my experience is often confusing.

The next step in sustaining process improvements involves linking strategic objectives to desired traits and behaviors. For more information on the steps involved in strategy deployment and aligning soft or social skills, check out Organizational Culture Change.

How are you working on sustaining your organizational improvements? How do you engage team members in strategy deployment and what challenges are you experiencing?