I’m often asked: “What should our leaders actually do in a Lean culture”? People want to know specific actions to guide their activities. They want a “recipe” to follow. Some folks want to wave a magic wand that suddenly transforms everything. Wouldn’t it be great if anything were so easy?

In reality, Lean has to be lived, felt, breathed, seen, and experienced. It must be reinforced by senior leaders who walk the walk and set high expectations for team members. When I was at Toyota, the Japanese trainers commonly used the word “behave.” At first, this sounded like the kind of directions we were given as kids in school, but when I thought more deeply about it, I realized they were speaking about particular behaviors. Behaviors and actions that created good habits, developed the character of team members, and fostered a learning culture.

So when I am asked about leadership and responsibility, I reply that lean leadership is a way of doing business, not simply a process to “think” through or try on for size. I call this idea (which really is a way to remember key behaviors and actions) “GTS4” (GTS to the fourth power)”. What does it mean? Here are the four steps involved in the GTS thinking process:

Go to See + Grasp the Situation + Get to Solution + Get to Standard = GTS4

The starting point for any lean thinking activity (and the beginning of the PDCA process) is Go To See (GTS), also known as Go To the Source (GTS). This habit is hard to develop, since we tend to rely on assumptions formed from our experience or from what someone has told us. My Japanese trainers would often say, “Please! Go Looking!” They may have known just a minimal amount of English, but we always knew what they meant. When I visit the gemba with clients they usually struggle to answer my questions because they lack the facts—the measurable data to work with. Instead, they have assumptions. It is only when we GO SEE and talk with the people who do the work every day that we can uncover the truth of what is really going on.

Why GTS4? Going to see is just the beginning. Once we GO SEE, we must then Grasp The Situation. We do this by asking the right questions! Let’s start with the three most essential questions a company and its leaders (at every level) should be asking themselves:

- What should be happening?

- What is currently happening?

- What is your measurable (gap) between the two above?

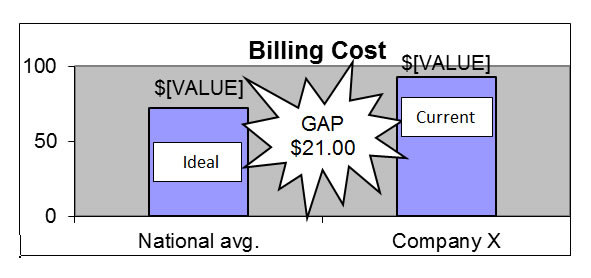

The first question is aimed at defining the ideal state, or standard. The second question defines your current state. Consider your problem as the gap between these two conditions. This type of “thinking” is really the first step in framing a problem in the Plan-Do-Check-Action (PDCA) process. In this clarifying the problem step, it is essential that you have a measurable “gap”. This enables the problem owner to see a measurable difference once the process is defined, root cause(s) found, and countermeasure(s) implemented. So the answers to these two questions should always be quantified! For example, this visual shows the Ideal-Current-Gap:

This gives us a $21 gap we can begin to break down and ask more questions about!

Most companies I work with (even ones you’d think should know!) can’t answer those three questions. As a result they have difficulty framing a problem as a simple gap between what should be happening and what is actually happening because the measurability just isn’t being tracked at the process.

I was raised with this thinking at Toyota, so these questions feel natural to me. But helping others develop this kind of thinking is a challenge. Too many leaders are too busy running around trying to fight fires or make fixes based on loose assumptions. This type of problem solving is weak at best, and surely not repeatable for long-term sustainability.

The next GTS is to Get to the Solution. If you have properly grasped the situation then this leads you to ask further questions like: What are the processes that address the gap? Then we look for the places, blocks, bottlenecks or “points of occurrences” within processes that help us understand root causes and finally, countermeasures. As mentioned above, this is PDCA. If we are able to complete this process by practicing the last GTS, and our countermeasures are effective, then we want to proceed to the fourth and final step: Get to Standard.

Knowing what to do as a leader can feel like an unwieldy question. But consider GTS4. It’s not easy, but it is fairly simple. The challenge is less a matter of being lean than it is asking ourselves if we are really practicing lean thinking—a way of thinking that starts by going to see, grasping the situation, getting to a solution, and ultimately, getting to a standard. It won’t feel natural at first, but it can be learned!