Establishing and following standardized work is an essential part of any lean transformation, serving as the foundation for kaizen. But in practice, many organizations struggle with issues of leadership, culture, and resistance when implementing or sustaining standardized work.

“The major challenge is convincing people to accept standardized work,” says Sammy Obara, a Lean Enterprise Institute faculty member and managing director of honsha.org, a San Diego-based lean consulting group comprised of former Toyota employees.

“The [surfing] culture was averse to a standardized approach. For example, they didn’t want to wear watches because they believed they could manage just as well by watching the sun.” |

Standardized work consists of a detailed, documented, and visual system that serves as a blueprint for people to follow to perform tasks in a predefined process. Typically centered around human movements, standardized work outlines efficient, safe work methods that help eliminate waste and serve as the baseline for kaizen, or continuous improvement.

Standardized work documents the current best practice, and as the standard is improved, the new standard becomes the baseline for further improvements.

In practice, some groups tend to be more open, while others are more resistant, to accepting and embracing standardized work. Not surprisingly, Obara has found that military organizations are among the best at following strict standardized work methods. Employees of pharmaceutical firms also tend to more readily accept standardized work, perhaps because they are accustomed to following the requirements of the Food and Drug Administration.

“In my experience, among those least likely to accept standardized work are surfing instructors who tend to be free-spirited in the way they approach their work,” says Obara. He speaks from the benefit of experience, having worked with the Pacific Surfing School (PSS) in San Diego to instill standardized work among the school’s dozen or so surfing teachers. “Realistically speaking, having surfers adhere to a more regimented procedure, where you have to respect standards, times, requirements and expected outcomes, is a miracle in itself.”

Surfers tend to take a loose, relaxed attitude toward the sport, so anything that smacks of regimentation naturally would be hard for them to swallow. “The culture was averse to a standardized approach,” Obara says. “For example, they didn’t want to wear watches because they believed they could manage just as well by watching the sun.”

After carefully observing the entire process of how PSS taught people to surf, Obara was able to break it down into half a dozen parts that made up a one-hour session:

- Fitting (boards and wetsuits);

- Communications (introductions, safety briefing, hand signs, whistle signs);

- Exercise (stretching);

- Land surfing (simulation);

- Rowing (getting out to catch a wave); and

- Surfing!

The first five steps took up so much of the hour session that when Obara clocked the time one surfer spent actually surfing, it was a total of five seconds standing up on his board on three waves.

|

3 Main Elements of Standardized Work |

For example, fitting took 10 minutes. As the dozen students Obara observed scrambled among one another to find the best-looking suits, some got the wrong size, boys got girls’ suits and vice-versa, while others got wetsuits that were still wet from previous use.

He suggested organizing the wetsuits in advance, assigning each student his or her own suit on a dedicated hanger so it could be picked up before the start of class. As a result, they were able to add 10 minutes of actual surfing time to the end of the lesson.

For the land surfing component, instructors showed each student where to place their feet on the board during each maneuver– i.e., getting up on the board, standing, acquiring balance, and finally picking up speed. Having placed one or both feet only a few inches to the left, right, forward or to the rear of the correct position often resulted in a wipeout once they stood and attempted to balance on the board.

Students had to repeat this 10 times, each time going from lying on the board on the sand in a simulation routine, to the standing position on the board. Some students would get their feet in the right places the first time, but most had to be shown where their feet belong.

Too much variability in foot placement on the board resulted in a student failing to get up. “If they couldn’t stand up on a board at the end of the class, they would get a free follow-up class,” Obara says. “Our solution was to put marks on the boards so the students could self-check the placement of their feet when doing this simulation exercise 10 times.”

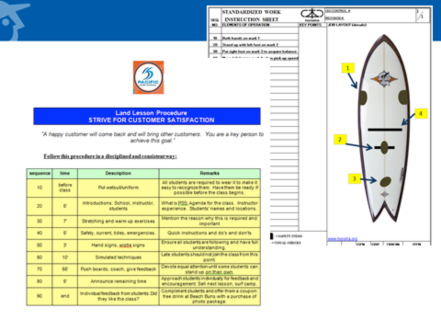

Two standardized work sheets developed at the Pacific Surfing School created a uniform curriculum (left) for instructors and a way for students to self-check foot placement (right) to practice correctly on land.

The owner of the surfing school, Emiliano Abate, convinced his people that the organization would fail if they did not implement standardized work, Obara says. “His leadership played a key role in getting people to follow his example and his commitment to standardized work,” Obara adds.

“The key ingredients that made this a success in my school were the example that we — the senior instructors and myself — showed the rest of the team,” Abate says. “And it was important to continuously ensure compliance to the new standards, which in the beginning had their share of resistance from the instructors.”

In the communications segment, instructors had different approaches to introduce all the students and themselves. In fact, the variability of instruction techniques used by the teachers afforded plenty of opportunities for improvement by applying standardized work.

“The key was to look at this type of business from a somewhat similar angle that manufacturing does,” Obara says. “I soon realized that the best perspective was to see students as the raw materials coming in, and an hour later, finished goods going out the door as surfers.

To find out if students at the Pacific Surfing School embraced standardized work, read the whole story here. Learn how to use standardized work to advance your continuous improvement efforts by attending the workshop Standardized Work: the Foundation for Kaizen with Sammy Obara.