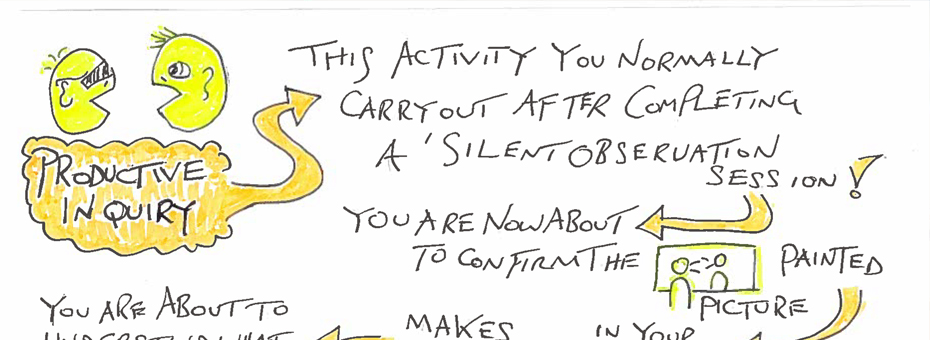

In my last release I explained how to perform “silent observation,” which is the preparation you do in advance of carrying out “productive inquiry.”

Productive inquiry is the step you take to verify and confirm something you observed, which either did or did not make sense to you. Often I have witnessed and confirmed through productive inquiry that tasks that made no sense to me actually were quite logical for the person doing the task. Why?

That person has created a workaround or nonstandard process to keep things moving. This is normally a direct result of support functions or supervision not responding to calls for help or addressing underperforming (minor stoppages) or problematic equipment that hinders the person doing the task. In effect, our lack of concern and action as management forces the team member to take action with the best intentions (they believe) to keep things running, but in reality they are only masking problems or creating waste or defects that could potentially impact the customer.

So talking to someone about what you saw is easy, right?

Wrong. What I have learned through many painful interactions is you MUST use open-ended questions, which ensure you get at least a sentence-length response. Their antithesis, closed-ended questions, are prone to getting you a simple “yes” or “no” response – which shuts down your line of inquiry pretty quickly.

The art of asking open-ended questions takes plenty of practice. You need to make sure the person you are talking to feels emotionally safe and comfortable with you, so tone of voice, posture and eye contact must be friendly. You should show concern and interest in helping them, not hindering them. Lastly, it is very important that you listen, let them talk and don’t interject. It’s 90 percent listening, 10 percent your input.

Check out my new sketch and animation to reinforce the learning opportunity and then just go practice, practice, practice.