Most of us think of the Deming Wheel of PDCA, Plan-Do-Check-Adjust as the most fundamental thought and action approach for continuous improvement. It’s been tested and proven many times over the decades. Yet is PDCA the role, the standard work of a lean coach? I don’t believe so, and think that if it was, it would be the waste of rework. I’ve found that a lean coach uses three deliberate practices that keep continuous improvement focused and purposeful.

The first deliberate practice of a lean coach is mindfulness. The practice of mindfulness is to frequently get a fresh observation, a new conscious “take” on what’s happening in the moment. An effective coach learns to be mindful and perceive “what is” without preconceptions or bias.

Second, a mindful coach would confirm or refine the purpose of the next improvement or experiment. For example, perhaps a machine is going out of calibration and the cause is unknown. A prior PDCA may have targeted improving the programming of the computer controls, but on second examination the purpose might change to a simpler “experiment” like switching the brand or hardness of inserts that do the cut the metal.

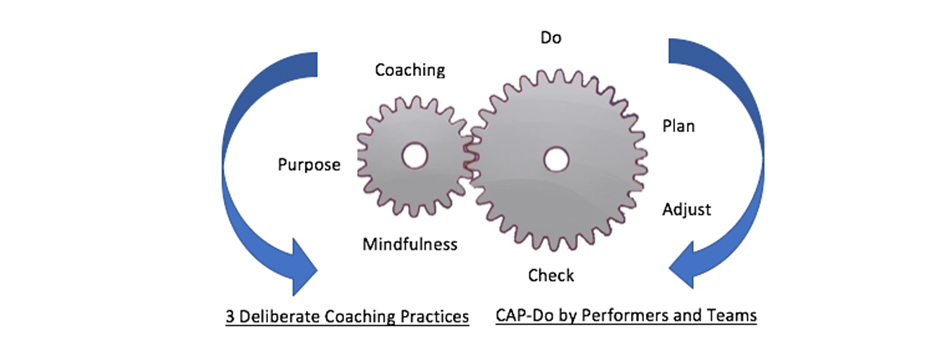

Third, a disciplined coaching method might be Socratic questioning, Toyota Kata, A3 people development, or just brainstorming kaizen ideas and doing quick experiments. The deliberate practices of mindfulness and purpose increase the quality, the focus of PDCA by Job performers and teams. The diagram below illustrates the three deliberate practices of lean coaching as a pinion gear that rotates an individual or team to do PDCA, pictured as a larger ring gear. The lean coach’s role isn’t promoting lean tools, checking metrics or process confirmation or following-up on previous kaizen events. It’s adding value by doing the three deliberate practices to keep the big PDCA gear spinning clockwise.

As the wheels turn toward each other, on the left side a lean coach would be mindful to grasp the situation and check plans on the right, then be purposeful in helping job performers adjust their plan, and finally use a deliberate coaching method to focus them on the “do”. A number of newer lean coaching methods are popular, including Toyota Kata, A3 people development, customer-back coaching, as well as old reliable, PDCA kaizen by doing quick experiments.

So a lean coach’s role isn’t PDCA; he or she uses the practices of mindfulness to grasp the always-new situation, and purpose to adjust improvement plans accordingly, and coaches a plan and experiment to close a gap. The coach’s role is to increase the quality of PDCA, not to do the PDCA. Every work situation evolves and new factors arise. Like change in work and life itself, continuous improvement needs to be constantly “new”.

Develop your coaching skills alongside other coaches at the Lean Coaching Summit, this July 18 and 19 with workshops on the 17th, in Seattle. Learn more at: http://leancoachingsummit.com/