Article

How Often Should We Change Takt Time?

Dear Gemba Coach: How often should we change takt time?

View article

Article

Ask Art: Why is Takt Time So Important in a Lean Turnaround?

Takt time represents the beat of the customer, or, the rate of demand, says Art Byrne: "As the primary focus of the lean company is…

View article

Article

Misunderstandings About Value Stream Mapping, Flow Analysis, and Takt Time

Value-stream mapping is not flow analysis, but rather a simple tool that guides you through the process of analysis to improve flows and design better…

View article

Article

How do I convince management to run to takt time, not as fast as possible?

Dear Gemba Coach: I have always struggled with convincing management about the importance of running to takt time, since the mindset is typically run as…

View article

Article

Takt Time Thinking for a Low-Volume High-Mix Company

Dear Gemba Coach: Our company produces custom products that cannot be easily forecast in terms of when they will be ordered, and in what format.…

View article

Article

How do you apply takt time to service work?

Dear Gemba Coach: How do you apply takt time in fields like services where customer demand is not known?

View article

Article

Ask Art: What Happens When Standard Cost Accounting Meets Takt Time?

Trying to become a lean enterprise while retaining traditional standard cost accounting is an exercise in futility. It was developed for a steady state environment…

View article

Article

Coaching Effectively Within Takt Time

When time is of the essence and work just needs to be done, how do you help someone improve their work or solve a problem…

View article

Lexicon Term

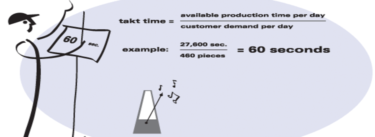

Takt Time

Takt time is a calculation of the available production time divided by customer demand. For example, if a widget factory operates 480 minutes per day…

Learn more

Article

Time To Make Time

When the people in a lean system don't value time, everyone is cheated, says John Shook, in this fascinating reflection on the role that time…

View article

Article

How Can Lean Take Root in a Crappy Culture?

Dear Gemba Coach: I've done a lot of working with lean, and recently started my first coaching/consulting gig. And while I'd love to help by…

View article

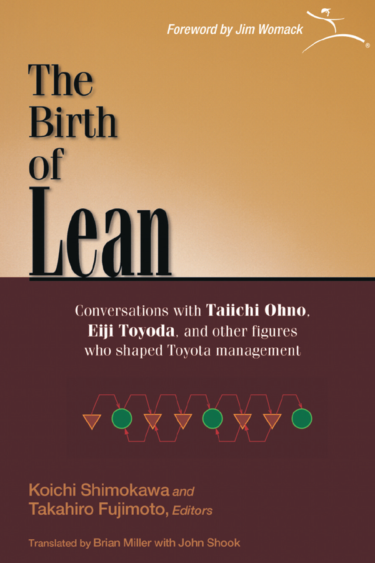

eBook

The Birth of Lean: Conversations with the Founders of TPS

Fascinating interviews with the founders of lean. Learn about the origins of the Toyota Production System from the people responsible for its creation. As its pioneers…

View event$30.00

Article

Why We Believe that Pull Flows Are Too Often Overlooked

In this incisive series of articles on the essential value of pulled flow, the lean sensei women argue, in the words of Catherine Chabiron, that…

View article

Article

Performance versus costs, part 2

Dear Gemba Coach: I’ve read your recent column on performance versus cost with great interest, as I believe we’re currently having a similar discussion at management…

View article

Article

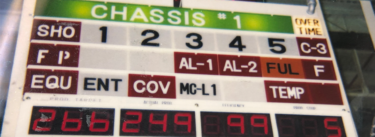

Are You Managing By The Right Numbers?

Knowing the key metrics to track will help you and your team start your learning journey, says Tracey Richardson. She shares the key figures that…

View article

Article

Learning to Help Anna Elevate Her Game

Anna was trained by NUMMI to identify and solve challenges via experiments with her team, notes Jeff Smith, sharing a story from NUMMI; she had…

View article

Article

Why does one-piece-flow matter?

Dear Gemba Coach: Recently, during a plant visit, our sensei made a big fuss because there were three parts between two operators and he insisted…

View article

Article

Are You Pulling?

Dear Gemba Coach: We’ve made a substantial effort in training all our operators to standardized work (SW) by deploying Training Within Industry(TWI) principles across all our…

View article

Article

I have years of experience in operational excellence but if I were to start lean where should I start?

Dear Gemba Coach: I have years of experience in operational excellence and have always assumed that lean is just a more gemba-focused way of improving…

View article

Article

Heijunka: Mastering the Peaks and Valleys

Struggling to run different types of products down one line? Lean coach Jeff Smith explains the lean manufacturing concept of Heijunka (or production leveling) by…

View article