Lean Events and Training

Seeking to meet your or your organization’s needs, LEI offers a wide array of learning opportunities

For Individuals and Teams

Coach-Led Online and In-Person Courses

Classroom-based, hands-on learning experiences led by LEI faculty online and in-person.

View allSummits

High-energy, inspirational gatherings where practitioners share actionable insights and network.

Learn moreLearning Tours

Unique opportunities to see firsthand outstanding examples of lean companies.

Learn moreFor Businesses and Organizations

Custom Training

Custom training and executive coaching designed to meet your needs precisely.

Customize your trainingEnterprise Transformation

LEI coaches help accelerate your lean journey and discover the best approaches to lean transformations.

Transform your companyUpcoming Events

Events by topic

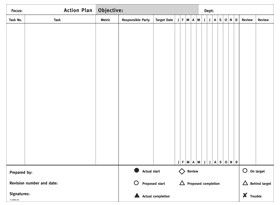

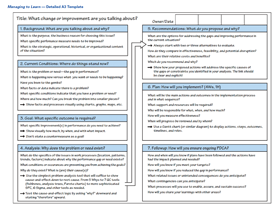

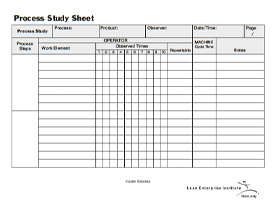

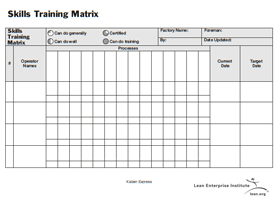

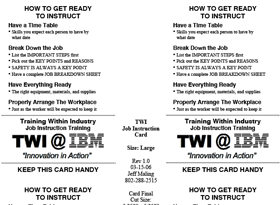

Forms and Templates

pdf 277.14 KB

pdf 464.27 KB

pdf 365.08 KB

pdf 261.82 KB

pdf 65.69 KB

xls 171.00 KB