Learn the systems-based method of new product, process, and service innovation that enables you to leverage your entire enterprise to create sustainable—and profitable—value streams.

Creating profitable value streams

Too often, organizations segregate the people developing new products, processes, and services innovation from the production and delivery parts of the business, fragmenting the value chain. This approach causes delays, cost overruns, quality problems, and a host of other issues. Worse, it can do tremendous damage both to the culture and overall performance of the organization. Lean Product and Process Development (LPPD) counters this tendency by bringing the entire organization together in the innovation process.

LPPD is a powerful system for developing new products and services, as well as the processes needed to produce and deliver them. Proven effective in companies large and small across diverse industries, it is more than merely a strategy for product development. It enables you to leverage your entire enterprise to build a sustainable system for consistently creating profitable value streams that, from the start, eliminate upstream issues.

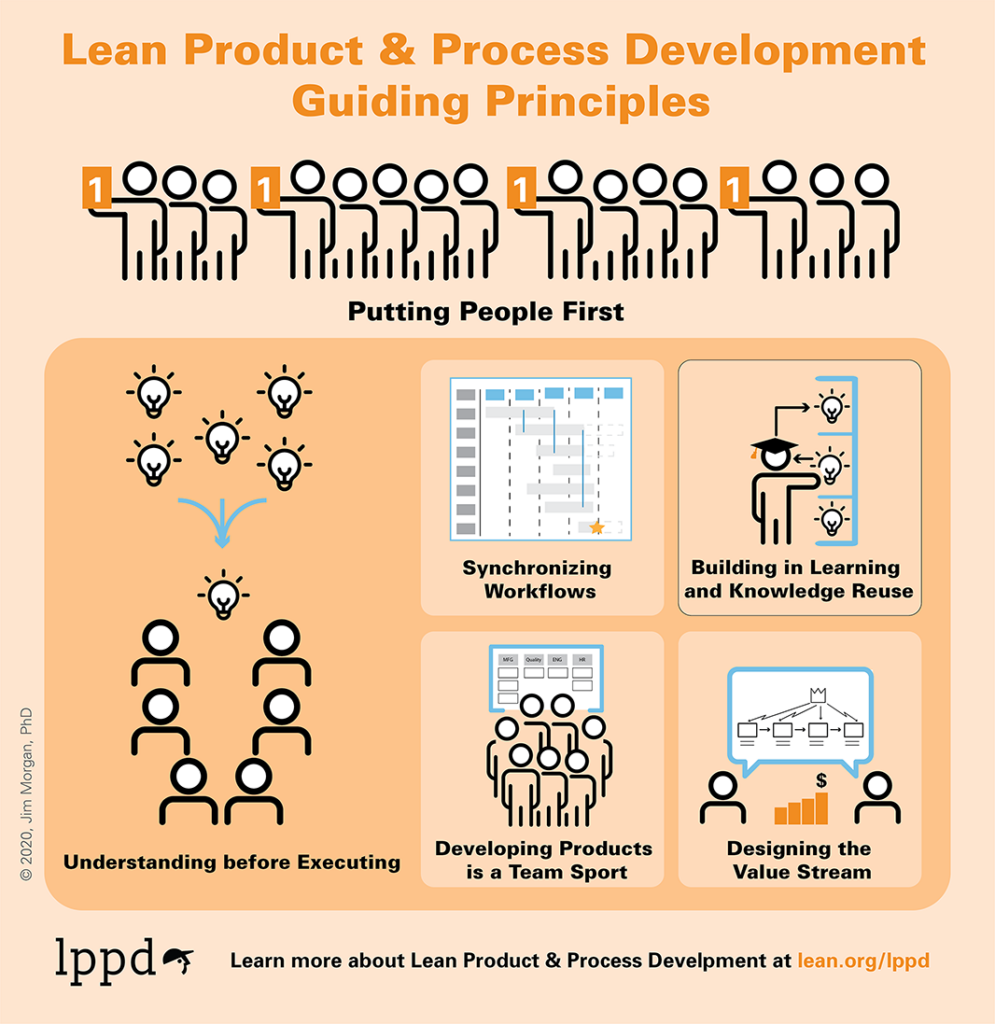

Lean Product and Process Development is built on six core principles:

- Putting People First: Organizing your development system and using lean practices to support people to reach their full potential and perform their best sets up your organization to develop great products and services your customers will love.

- Understanding before Executing: Taking the time to understand your customers and their context while exploring and experimenting to develop knowledge helps you discover better solutions that meet your customers’ needs.

- Developing Products is a Team Sport: Leveraging a deliberate process and supporting practices to engage team members across the enterprise from initial ideas to delivery ensures that you maximize value creation.

- Synchronizing Workflows: Organizing and managing the work concurrently to maximize the utility of incomplete yet stable data enables you to achieve flow across the enterprise and reduce time to market.

- Building in Learning and Knowledge Reuse: Creating a development system that encourages rapid learning, reuses existing knowledge, and captures new knowledge to make it easier to use in the future helps you build a long-term competitive advantage.

- Designing the Value Stream: Making trade-offs and decisions throughout the development cycle through a lens of what best supports the success of the future delivery value stream will improve its operational performance.

Learn more about each LPPD principle by watching the following brief videos:

The LPPD Guiding Principles provide a holistic framework for effective and efficient product and service development, enabling you to achieve your development goals.

By promoting early consideration for not only what gets made but how it will be made, the LPPD process identifies and addresses potential upstream problems in the design phase, so rework in upstream stages is considerably reduced or eliminated.

In this brief animation, Jim Morgan, LEI senior advisor, lean product and process development (LPPD), offers an overview of this unique set of principles, methods, and tools that has been proven effective in helping organizations create value for their customers.