James (Jim) Womack, PhD

Founder and Senior Advisor

Lean Enterprise Institute

Widely considered the father of the lean movement, Womack has been talking and publishing about creating value through continuous innovation around deep customer understanding for many years. In the late eighties, he and Dan Jones led MIT’s International Motor Vehicle Research Program (IMVP), which introduced the term “lean” to describe Toyota’s revolutionary management system.

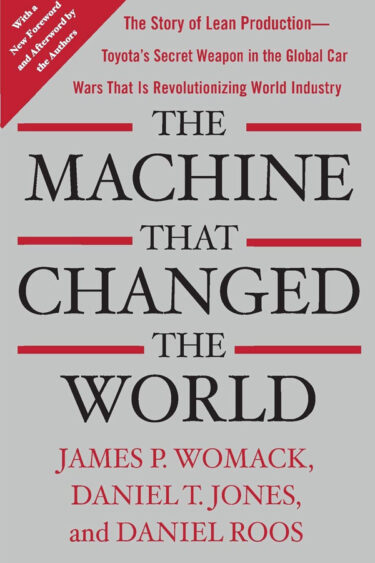

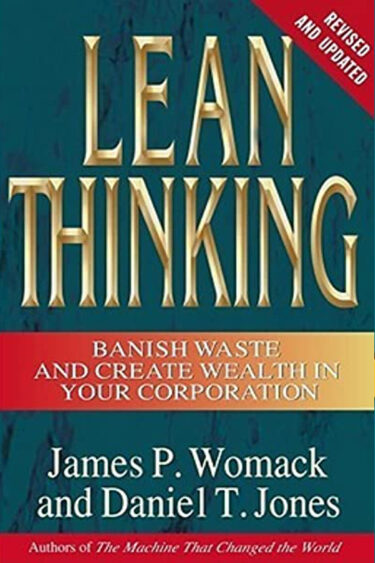

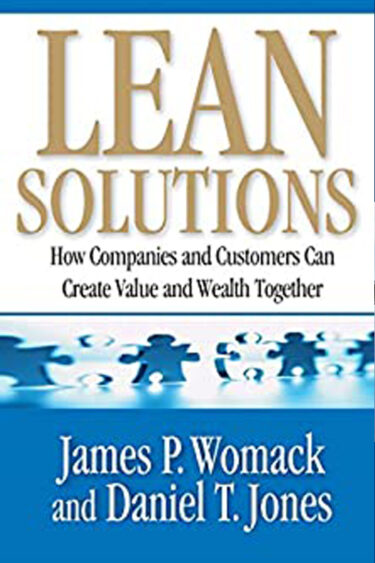

Based on that research, Womack coauthored The Machine That Changed the World (Macmillan/Rawson Associates, 1990), Lean Thinking (Simon & Schuster, 1996), Lean Solutions (Simon & Schuster, 2005), and Seeing the Whole Value Stream (Lean Enterprise Institute, 2011).

In addition, he founded the Lean Enterprise Institute in 1997 as a nonprofit research, education, publishing, and conferencing company to ensure new knowledge about lean thinking and practices would be available to the worldwide public, making things better for individuals, organizations, and society. Womack’s leadership of LEI inspired global efforts to establish lean institutes in other countries, which ultimately grew into the Lean Global Network, chartered in 2007.

Other significant articles Womack wrote include: “From Lean Production to the Lean Enterprise” (Harvard Business Review, March-April, 1994), “Beyond Toyota: How to Root Out Waste and Pursue Perfection” (Harvard Business Review, September-October, 1996), “Lean Consumption” (Harvard Business Review, March-April, 2005).

He received a PhD in political science from MIT in 1982 (for a dissertation on comparative industrial policy in the U.S., Germany, and Japan), a master’s degree in transportation systems from Harvard in 1975, and a bachelor’s degree in political science from the University of Chicago in 1970.