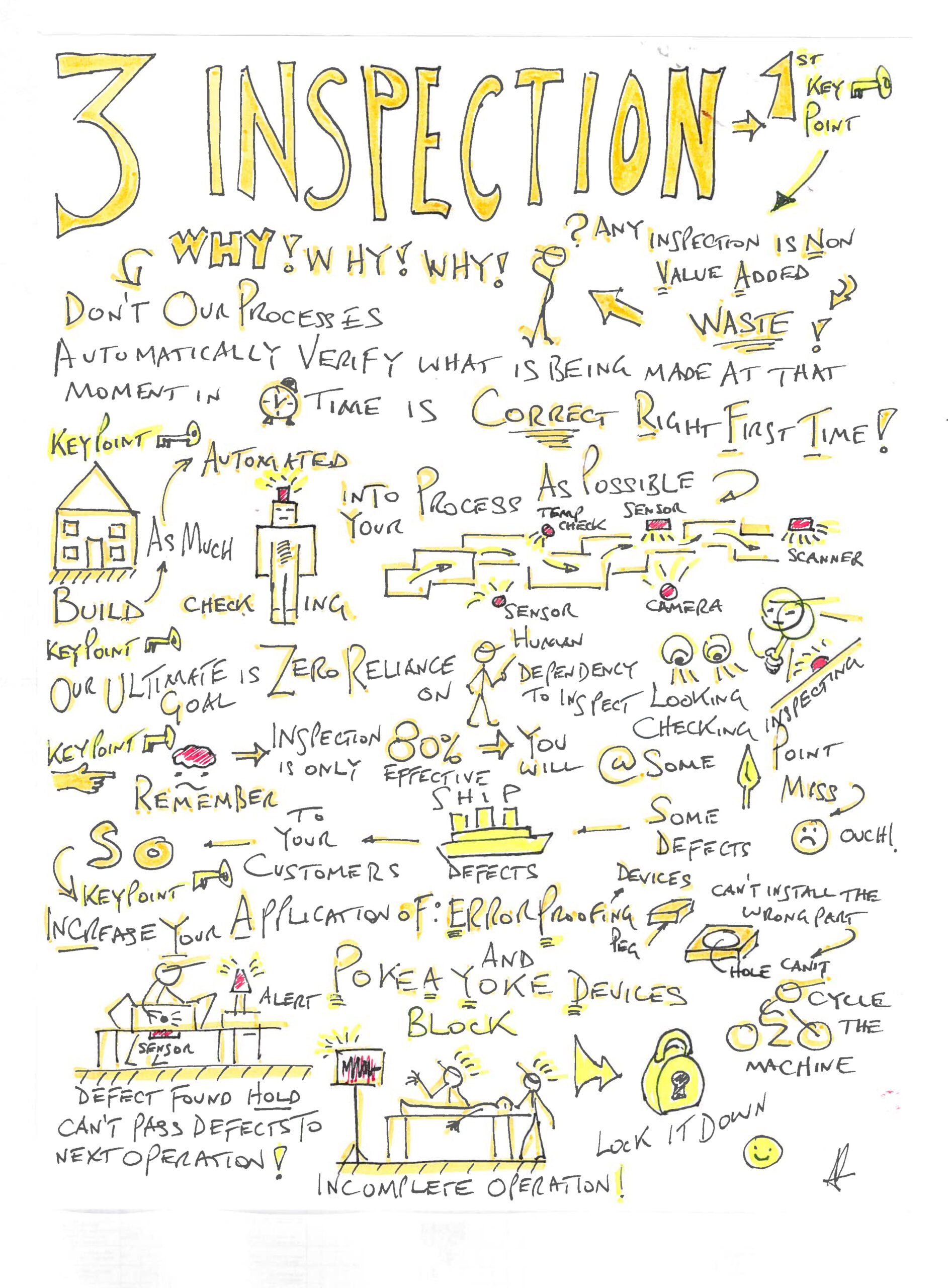

Inspection: Is it a necessary evil? That’s always a good opening line to get the debate going, but one thing is for sure: it is waste!

When I tell plant managers that their reliance on Inspection is a cause for some of their self-inflicted muda, nine times out of 10 they look at me like I have three heads. How on earth, they argue, could Inspection be wasteful? Isn’t Inspection where waste gets caught and eliminated?

Pause and think about that statement for a moment…paying people to check other people’s work? Moving product to inspect it (conveyance waste) and holding product to inspect it (wasted time and tied-up inventory) don’t sound like very healthy business practices to me.

Our goal with lean is to build processes (not necessarily human-dependent) for checking for defects. This could involve enhancing our quality assurance (QA) capability within the process itself (using andons, for instance) or applying automated checking applications, if funding allows. The bottom line is, the more we rely on human dependability in Inspection, the more defects are likely to slip through the cracks.

It’s built-in quality that is the key to eliminating waste as a consequence of having to have Inspection. And it should be in the form of error-proofing and poka-yoke devices – when we accomplish that we create the robust, right-the-first-time processes we need to make defect-free products

My new sketch and animation video explain more about the waste in Inspection. Once you’ve reviewed them, I ask you to think about how you have your processes set up…have you fully grasped error-proofing opportunities? Do you provide your employees with the means to call for help to stop defects being passed downstream?

Maybe it’s time to re-think your current approach…

I’m an inspector, we have over 10000 parts. They range from simple bushings to PC boards and sensors,

If I let them slide thru without any look. The crew will assemble the $ 50k machines that are calibrators. and try and test them and spend weeks trying to find the reason they wont work. (hidden waste) If that’s not enough the silk screen on the covers or front panels is feathered, it is not legible or it looks like someone drew the operating instructions with a felt marker. Machine parts have threads and flat surfaces that require very close tolerances for sealing and functioning,. How much time is wasted running to the line and tapping a thread. We have many vendors, and no we can’t allow them to inspect everything they send us because of cost. plain and simple. However I still use 9 wastes of manufacturing to improve and we are in constant communications with vendors when we do have issues. It is more cost effective to inspect especially today world where everything cost 3 times more a 14 dollar gear in china will cost 200 in the us. 1 inspector could save hundreds of thousands every year I’m on year 18.