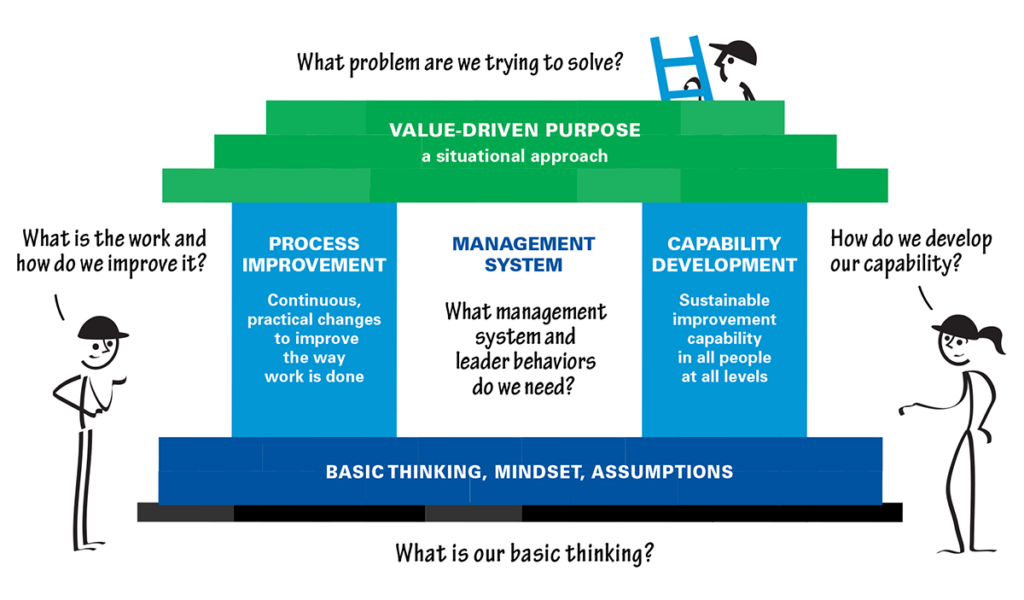

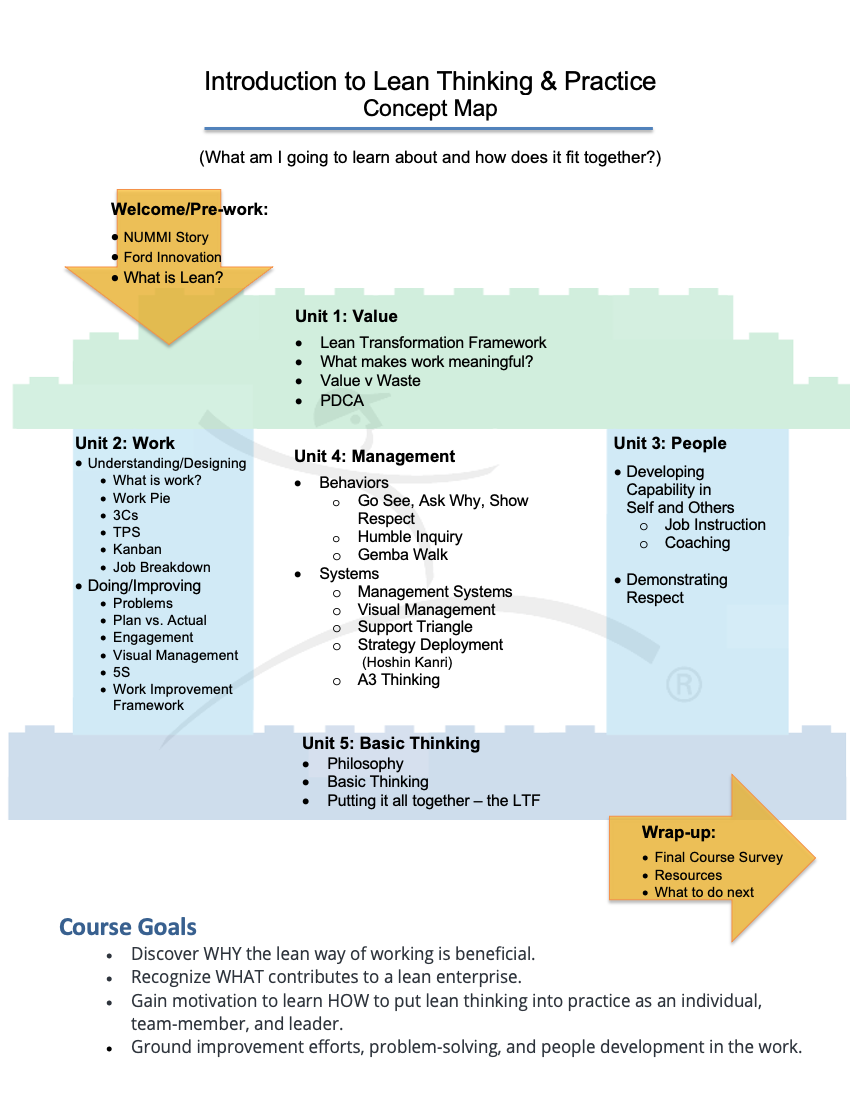

Intro to Lean Thinking & Practice

An introduction to the essential concepts of lean thinking and practice.

Location

Online – On-Demand, Self-Paced

Why you should attend

Get a comprehensive introduction to the essential concepts of lean thinking and practice, including the philosophy, principles, practices, and tools.

Cost

$249 Users will have access for 12 months