Engage in a learn-by-doing experience, applying lean practices and using lean tools to observe and understand work processes at the level of detail required to improve them.

Observations Skills Course (formerly called Work Observation) defines, provides examples, and explains the role work-observation skills play in the broader context of lean thinking and practice. These skills include:

- Showing respect

- Identifying value

- Breaking down and measuring work steps

- Making work visible

- Using observations to make business decisions.

You’ll learn how these skills help cultivate a lean culture by basing work process experiments — and ultimately, changes — on observed facts gathered through work observation.

Through case examples and completing interactive, hands-on exercises, you’ll engage in short, precise learning materials that explain, illustrate, and have you practice using critical concepts.

Who Will Benefit?

- Leaders, from mid-level managers to top executives, including continuous-improvement and human-resources leaders, who need to level up their team’s knowledge of lean work improvement thinking and practices

- Beginning lean practitioners looking to boost their career prospects

- Professionals who want to improve their work processes using lean thinking and practice

- Lean practitioners seeking to fill in learning gaps or refresh their knowledge

What Will I Learn?

Upon completion, you will be able to:

- Foster a positive and collaborative environment by respectfully approaching people whose work you plan to observe.

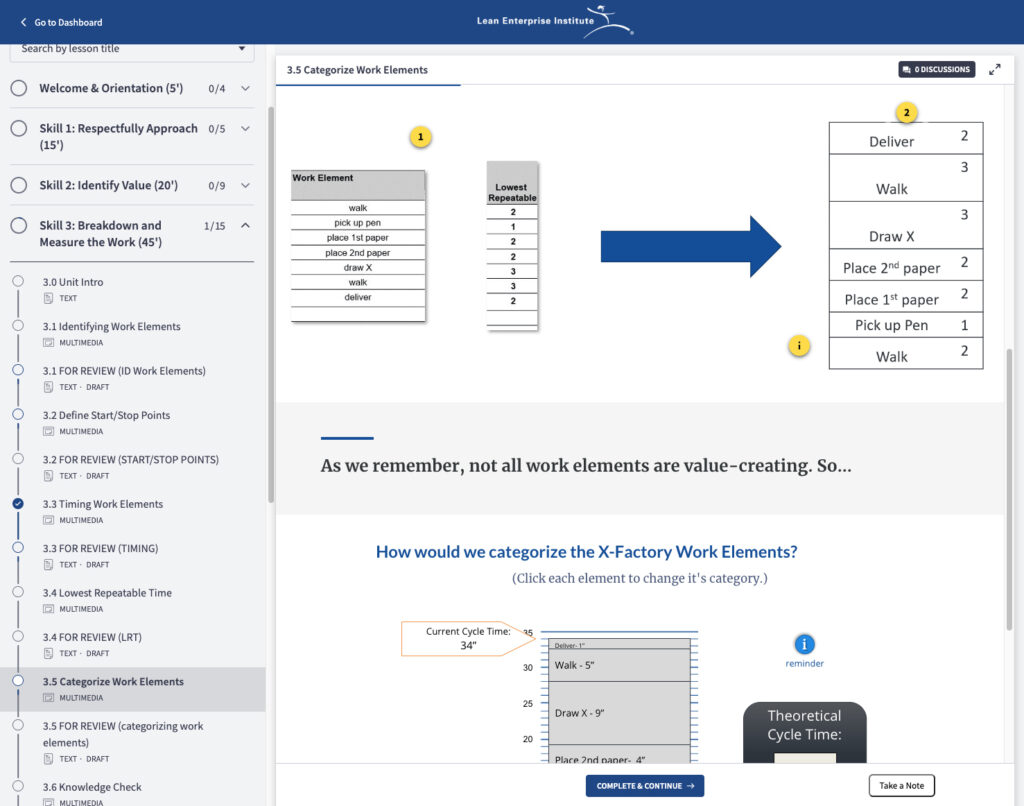

- Distinguish between value-added and nonvalue-added parts of work processes.

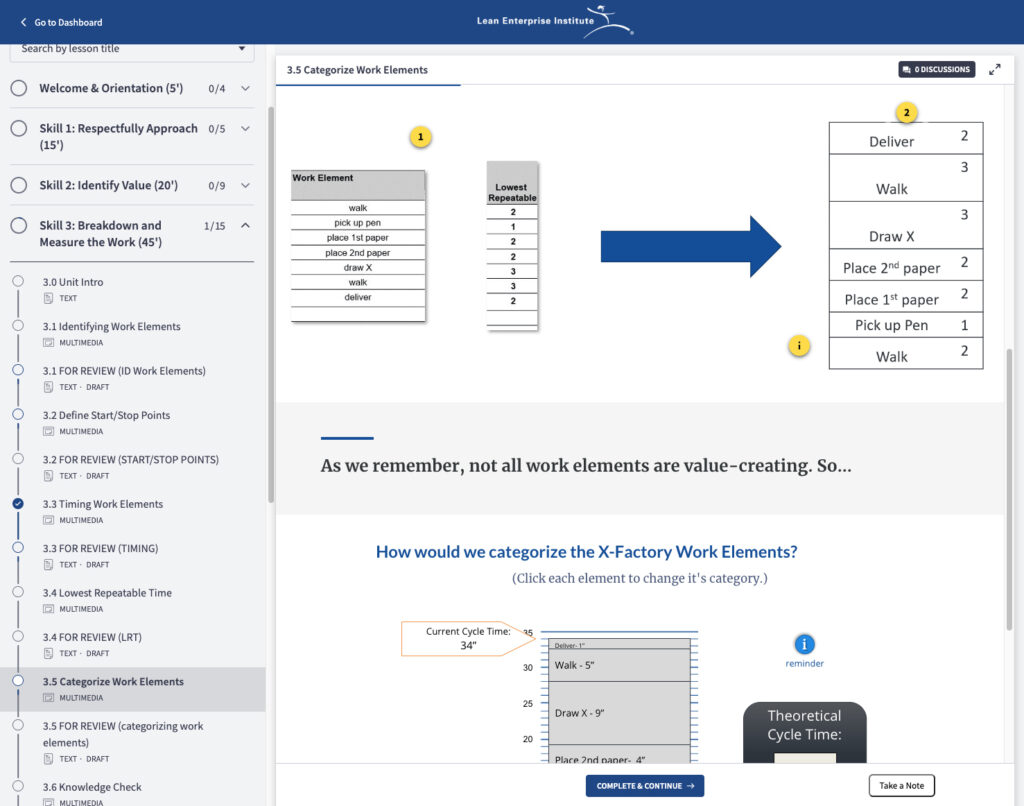

- Break down and measure each work process step using a Process Study Sheet.

- Make work steps visual by drawing an Operator Balance Chart.

- Leverage your observations to make business decisions.

- Use lean tools to align with frontline workers throughout your organization.

Related Courses:

Though no prerequisite training or reading is required, having familiarity with lean management basics will be helpful. We recommend the following courses.

Throughout this self-paced digital course, you will review examples, complete practice exercises, participate in community discussions, and take time for self-reflection.

Completing the entire journey will take an estimated minimum of 3.5 hours. Learners have the option to engage with additional resources, hands-on exercises, and reflection questions; as result, the time will vary.

Welcome & Orientation

5 minutes

Skill 1: Respectfully Approach

15 minutes

Skill 2: Identify Value

20 minutes

Skill 3: Breakdown & Measure Work

45 minutes

Skill 4: Make Work Visual

45 minutes

Skill 5: Make Business Decisions

60 minutes

Final Reflection

10 minutes