Article

Isn’t there a better way to manage inventory than just-in-time?

Dear Gemba Coach, This is 2019. Isn’t there a better way to manage inventory than just-in-time by now?

View article

Article

It seems that lean these days is all about learning and coaching. What about the good ol'-fashioned just-in-time stuff of the earlier days?

Dear Gemba Coach: It seems that lean these days is all about learning and coaching. What about the good ol'-fashioned just-in-time stuff of the earlier…

View article

Article

The Sanity of Just-in-Time

Path dependence is the worst enemy of smart resolution, argue the authors, who suggest greater "frame control" with enabling tools such as just-in-time to respect…

View article

Article

Lean Enterprise Institute Responds to The Wall Street Journal's Mischaracterization of Just-in-Time

A message from LEI to the Lean Community

View article

Article

LEI Responds to The Wall Street Journal's Mischaracterization of Just-in-Time

LEI's response to the August 21 Wall Street Journal article that mischaracterized Just-in-TIme.

View article

Article

Just-in-Time Roundup: Great Lean Reads from Across the Web (Vol. 4)

LEI editors share an interesting assortment of lean-themed and lean-related articles from across the web, this time from Harvard Business Review, strategy + business, Planet…

View article

Article

Just-In-Time Roundup: Great Lean Reads from Across the Web (Vol. 2)

Check out our editors' picks for great lean reads you may have missed, featuring stories from The Atlantic, The New Yorker, Harvard Business Review, and…

View article

Article

Just-in-Time Roundup: Great Lean Reads From Across the Web (Vol. 5)

Check out our editors' picks for 5 high value lean reads you may have missed, this time from Industry Week, the blog at ThedaCare Center…

View article

Article

Just-in-Time Roundup: Great Lean Reads from Across the Web (Vol. 3)

LEI editors have gathered another five articles that either teach us something new about lean practice or show us where lean thinking is being applied…

View article

Lexicon Term

Just-in-Time Production

Just-in-time is system of production that makes and delivers just what is needed, just when it is needed, and just in the amount needed. JIT…

Learn moreArticle

Just-in-Time Roundup: Great Lean Reads from Across the Web (Vol. 6)

Check out five recently published articles we think may help you improve your work or think about your work differently - this time from Forbes,…

View article

Article

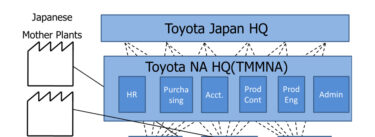

Pivoting Just-In-Time with Hoshin Kanri at Toyota

Learn about the power of hoshin kanri, a systematic approach to defining a strategy and, more importantly, a management system that engages all people to…

View article

News

The Downside of Just-in-Time Inventory

Near the end of this article, James Womack, founder of the Lean Enterprise Institute in Cambridge, MA, notes that companies won’t abandon just-in-time production because…

Learn morePress Release

Just-in-Time Coaching Is the Theme of the 2018 Lean Coaching Summit, Co-Sponsored by the Lean Enterprise Institute and Lean Frontiers

Increasing competition means busy leaders must learn how to deliver their regular work while simultaneously coaching employees to continuously improve processes. The solution is “just-in-time…

Learn moreArticle

Just-in-Time Roundup: Great Lean Reads From Across the Web (Vol. 7)

Five recent articles from across the web to help you reflect on your organization's approach to lean transformation or your own approach to work. Which…

View article

Article

Just-in-Time Roundup: Great Lean Reads from Across the Web (Vol. 8)

Check out our picks for high value lean reads you may have missed - this time from Inc., Harvard Business Review, Planet Lean and more.

View article

Article

Just-In-Time Roundup: Great Lean Reads From Across the Web

We're trying something new on the Post rounding up some of the best or more interesting lean-themed articles from around the web. Our goal? Make…

View article

Article

Just-in-Time Roundup: Great Lean Reads Across the Web (Vol.10)

Our latest picks for great lean reads across the web, this time from 99u, strategy + business, a hotel app company's blog, Stanford Social Innovation…

View article

Article

Just-in-Time Roundup: Great Lean Reads from Across the Web (Vol. 12)

Our latest compilation of lean reads from around the web, this time featuring articles from Stanford Medicine, the Association for Talent Development, and Insurance Business…

View article

Article

Just-in-Time Roundup: Great Lean Reads from Across the Web (Vol. 16)

Our editor's picks for the best lean news from around the web, this month from Harvard Business Review, FedScoop, and IndustryWeek!

View article