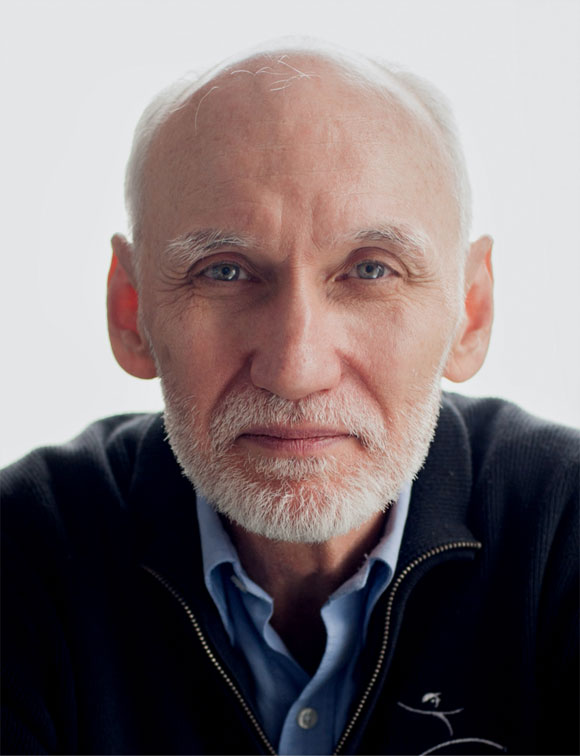

John Shook

Senior Advisor, Lean Enterprise Institute

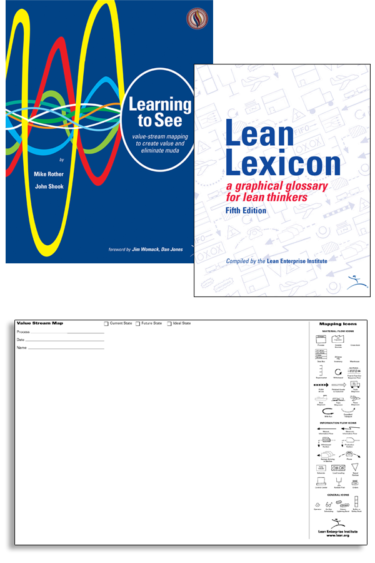

John Shook learned about lean management while working for Toyota for 11 years in Japan and the U.S., helping it transfer production, engineering, and management systems from Japan to NUMMI and other operations around the world. While at Toyota’s headquarters, he became the company’s first American kacho (manager) in Japan. In the U.S., Shook joined Toyota’s North American engineering, research and development center in Ann Arbor, Michigan as general manager of administration and planning. His last position with Toyota was as senior American manager with the Toyota Supplier Support Center in Lexington, Kentucky, assisting North American companies adopt the Toyota Production System. Shook co-authored Learning to See, the book that introduced the world to value-stream mapping. He also co-authored Kaizen Express, a bi-lingual manual of the essential concepts and tools of the Toyota Production System. With Managing to Learn, Shook revealed the deeper workings of the A3 management process that is at the heart of Toyota’s management and leadership.

Shook is an industrial anthropologist with a master’s degree from the University of Hawaii, a bachelor’s degree from the University of Tennessee, and is a graduate of the Japan-America Institute of Management Science. At the University of Michigan, he was director of the Japan Technological Management Program and faculty member of the Department of Industrial and Operations Engineering.

Shook is the author of numerous articles, including “How to Change a Culture: Lessons from NUMMI”; Sloan Management Review, January 2010, which won Sloan’s Richard Beckhard Memorial Prize for outstanding article in the field of organizational development.