Time and again, I have seen companies that struggle to create an effective management system pay the price in their performance. Indeed, research that looked at the management practices and performance of 12,000 firms from across 34 different countries reveals that healthy management and operational excellence are a competitive advantage: “If you look at the data, it becomes clear that core management practices can’t be taken for granted… Firms with strong managerial processes perform significantly better on high-level metrics such as productivity, profitability, growth, and longevity. In addition, the differences in the quality of these processes — and in performance — persist over time, suggesting that competent management is not easy to replicate.”

The authors behind the research further note, “Achieving managerial competence takes effort, and it requires sizeable investments in people and processes throughout good times and bad. These investments, we argue, represent a major barrier to imitation.”

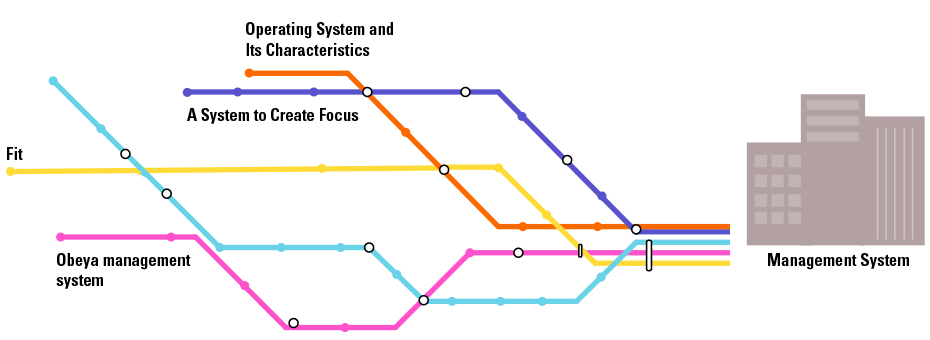

I agree, and in our book, Designing the Future, my co-author Jeff Liker and I share our belief that, while the term management system is used in different ways, we believe a management system is the product of two elements — leadership behaviors and an operating system (LB*OS=MS). If either multiplying factor is weak, then the resulting product is diminished.

Leadership behaviors and your operating system are interdependent. There is no operating system you can possibly devise that can anticipate every possible failure mode or compensate for incompetent leadership. When companies try to do this, though often well-intended, the result is a suffocating bureaucracy. As W. Edwards Deming said, “A bad (operating) system will beat a good person every time.”

Good leaders energize and bring life to a management system, and an effective operating system can focus and magnify leadership effectiveness just as a poor one can diminish it.

A strong management system requires you to strengthen both elements. You can’t (and shouldn’t) take people and their skills and judgment out of the equation. Good leaders energize and bring life to a management system, and an effective operating system can focus and magnify leadership effectiveness just as a poor one can diminish it. A great deal has been written about good leadership, but what is an effective operating system?

Creating an Operating System

An operating system is made up of the tools, processes, standard work, cadenced activities, and other mechanisms that enable the work to get done. If a leader is the craftsman, then the operating system is his or her collection of tools. But a good operating system is far more than the sum of its parts.

If a leader is the craftsman, then the operating system is his or her collection of tools.

An effective operating system moves an organization toward its objectives in order to accomplish its mission. It creates a cadence of regularly occurring management activities instead of episodic management interventions. It is a single, integrated system, not a hodgepodge of departmental plans that do not hang together. It is transparent, multileveled, and cascades throughout the organization. It establishes objectives, allocates resources, and provides clear, aligned roles and responsibilities in order to deliver the plan. It provides the structure that enables (or inhibits) people to do their work. It knits together and drives critical value-creating activities, such as strategy deployment, continuous improvement, new product delivery, people development, and working environment, manufacturing, and supply chain. Finally, the operating system provides performance feedback on how you are doing.

An effective operating system helps bring strategy to life. It synchronizes critical activities, enables the organization to respond quickly to a changing environment, and allows plans and teams to move together. And when executed with discipline and coupled with effective leadership behaviors, it provides a tremendous competitive advantage for any organization.

An operating system should accomplish six basic things:

- Deploy your organizational strategy, align your organization, and allocate resources to ensure success.

- Drive the creation of new value through products and services that your customers truly value.

- Support daily operations, providing support for the basic work of the organization.

- Develop people and create a great work environment. This should be designed to provide a competitive advantage for years to come.

- Provide ongoing system-performance feedback and enable continuous improvement. The system should have a built-in improvement and course-correction capability.

- Create a framework for manager standard work. This framework should provide a disciplined cadence of management activities (daily, weekly, monthly, quarterly) that organizes leaders’ work and enhances their effectiveness.

Building a System that Increases Focus

Successful organizations are able to focus their energy and limited resources on delivering their plan. Companies without good management systems are often unable to do this, which was certainly the case when Alan Mulally arrived at Ford in 2006. At the time, there was no shortage of initiatives to improve organizational performance. Improvement programs were simply layered one on another, all competing for precious time and resources. Unfortunately, these chaotic initiatives served primarily to create organizational drag, squandered resources, and created a sense of cynicism among people.

So, what was the problem? In large part, it was the lack of an effective management system to align the company.

And we don’t believe lack of organizational focus to be an unusual problem. Stanford professor Jeff Pfeffer explains, “Companies have managed to convince themselves that, since what gets measured is what gets done, the more they measure, the more stuff will get done.” He shared a conversation he had with a woman who works for a large oil company that had 105 metrics for which she was responsible. How many did she actually pay attention to? Her answer was zero. It was just too overwhelming. And this behavior has led professor Pfeffer to what he calls his “Otis Redding Theory of Measurement,” named for Redding’s song Sitting on the Dock of the Bay. In the song, Redding sings, “I can’t do what ten people tell me to do, so I guess I’ll remain the same.” When faced with too much, people will inevitably do too little or nothing.

We believe that the focus created by Alan’s working together management system and the focus it created was one of the most important elements of Ford’s turnaround. With its disciplined cadence, his operating system clarified priorities and focused initiatives, leveraging their interdependencies toward a common set of goals. And, perhaps most importantly, it enrolled everyone in the effort.

Using an Obeya Management System

The obeya management system is another excellent example of an effective management system. Obeya meetings act as “superchargers” to align participants, build team momentum and confidence, and continually move the program forward. The obeya system also extends leadership effectiveness and provides a forum to demonstrate best leadership behaviors. The obeya management system creates a disciplined cadence and a high level of transparency for the entire team, which leads to much greater inclusiveness and collaboration, improved problem-solving, and faster and better decision-making. With obeya, like Mulally’s system, the combination of a disciplined cadence, transparency, and inclusive leadership naturally creates a high level of focus, accountability, and improved performance.

Ensuring Alignment

It is worth repeating: To reap the benefits of an effective management system, organizations must align the operating system and leadership behaviors. For example, the operating system elements of obeya and A3 are exceptionally effective in promoting transparency, problem-solving, and collaboration. But if leaders “do not want to hear problems,” attack people who surface issues, or don’t use the tools or collaborate with their colleagues, you can forget it. If you install an operating system that includes annual strategy deployment and a cadenced reviewing process to promote focus, but leaders continually chase after the next shiny object, what’s the use? This lack of alignment is often behind comments like “Oh we tried obeya or A3 or whatever … and it didn’t work here.”

Tools are just tools without a skilled craftsman. Both your operating system and leadership capability should be continually and intentionally nurtured and evolved such that they are mutually reinforcing and always improving.

Subscribe to the Design Brief Newsletter for information, insights, and inspiration — articles, videos, and interviews with coaches and practitioners who are pioneering more effective ways to develop new products and services.

Managing a Lean Enterprise

Learn how to drive performance and inspire innovation using hoshin kanri, daily management, and A3 process.

Great article and reminder of the multiplying or crippling impact of leader behaviors. Organizations thrive when the culture allows leaders to provide the “helpful help” needed to solve problems at the root cause. Too often, however, culture can even over power the well intentioned leader. The Operating System affords both the team and the leader to look at the problems with facts and data that focus on solving the problem rather than blaming individuals.