Article

A Trip to the Dentist That You’ll Enjoy

At AME's annual conference in Covington, KY, two weeks ago, Sami Bahri used his book, Follow the Learner, to base a great one hour keynote,…

View article

Article

Lean Beyond Production

Read how Lean Thinkers, using the same lean tools that worked in production, now are making improvements and benefits off the plant floor, in environments…

View article

Article

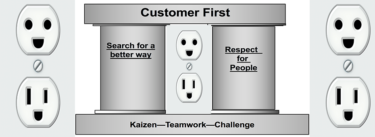

LEAN = TPS {KAIZEN + RESPECT}

Dear Gemba Coach: In the webinar, you’ve defined LEAN = KAIZEN + RESPECT. Isn’t it simplistic? Is that all there is to it? What about TPS?

View article

Article

Lean and Forecasting

Dear Gemba Coach: I’m in charge of the forecasting department in my company. My colleagues in production have been doing lean for several years and…

View article

Article

Survive to Make Money or Make Money to Survive?

With GM’s demise becoming more real every day, many people have been asking me, “Why didn’t GM learn from Toyota when they had the perfect…

View article

Article

Ask Art: Why Do Most Companies Think Of Lean as Just a Cost Reduction Program?

We shouldn’t be surprised at all that most companies approach lean as a cost reduction program, when it really is better understood as a time-based…

View article

Article

Surfer Culture Meets Standardized Work

Can surfing instructors and students really learn standardized work? Read the surprising story of how lean coach Sammy Obara worked with Pacific Surfing School to…

View article

Article

Does lean change how you think about business?

Dear Gemba Coach: I can see that lean changes how one thinks about business, but can’t quite put my finger on it. If you had…

View article

Article

Why Coaching is a Core Skill of a Lean Leader

If "learning by doing" at the gemba is the best way to learn lean thinking and practices (and it is), coaching is THE skill leaders…

View article

Article

Ask Art: How Does Lean Apply to Every Company?

Lean veteran Art Byrne shares a back-to-basics explanation of why — and how — lean thinking and practices can improve the performance of any company…

View article

Article

Once Again, Here's Why JIT Matters

Jeffrey Liker argues that recent media snipes fail to understand the crucial role JIT plays in a complete #lean system in surfacing problems & pressuring…

View article

Article

Lean Physician, Heal Thyself!

"We [need] to equip people with the right tools to address the problems they must solve," writes Phil Coy. "New software is emerging that is…

View article

Article

What is the difference between standard work and procedures?

Dear Gemba Coach: What is the difference between standard work and procedures?

View article

Article

Ask Art: Why Are Leaps of Faith Involved in a Lean Turnaround?

Leaps of faith are not incidental associations with a lean turnaround; they are a basic requirement, argues lean veteran Art Byrne.

View article

Article

How Wiremold Reinvented Itself Through Kaizen

Art Byrne shares a seminal 25-year-old article recounting how Wiremold tapped Kaizen to support a complete lean turnaround that continues to inspire and instruct people…

View article

Article

A Philanthropic 'Lean Internship' Experiment Yields Unexpected Question About Purpose

To understand what could work in a hands-on, gemba-based lean learning experience, the LEI's JPW Fund did what lean practitioners do — they ran a…

View article

Article

Why does visual management at a Toyota plant look so much different than at ours?

Dear Gemba Coach: We have been deploying lean visual management in my company for a while now, and I am troubled because I finally visited…

View article

Article

Ask Art: How Well Do Companies Follow Toyota's 'Respect for People' Principle?

Comparing traditional command-and-control management shows why this lean management tenet benefits both employees and the organization.

View article

Article

Ask Art: At What Pace Should A Lean Turnaround Be Implemented?”

Changing from a traditional batch, make-the-month culture to a lean value driven culture takes a lot of time and effort, says Art Byrne. The faster…

View article

Lexicon Term

Standardized Work

Establishing precise procedures for each operator’s work in a production process, based on three elements: Takt time, which is the rate at which products must…

Learn more