Be among the first to get the latest insights from LEI’s Lean Product and Process Development (LPPD) thought leaders and practitioners. This article was delivered to subscribers of The Design Brief, LEI’s newsletter devoted to improving organizations’ innovation capability.

When asked if “chasing cheap labor” was the reason Apple located the lion’s share of their manufacturing in China, the tech titan CEO Tim Cook said China is no longer a low-cost country. The reason he said that they produced in China was because of the abundance of highly skilled, precision tool makers, manufacturing engineers, and innovative production equipment suppliers that were located there. A skill he said the US sadly lacked in the numbers necessary to meet Apple’s quality and productivity requirements.

Ben Armstrong, executive director of MIT’s Industrial Performance Center, said on this month’s Design Brief podcast that this is not just an issue for Apple; it’s negatively impacting the US across nearly all industry sectors. Based on my own, experience of working both in and with

a variety of companies, I think many, if not most, do not have a sufficient appreciation of the contribution this discipline can make to their ultimate success.

… all the post-launch kaizen ideas in the world will have only a tiny fraction of the impact those same ideas could have had during development.

I also suspect that the lean community’s continued over-focus on post- launch operations is at least partially due to a lack of understanding of this work. But one thing is certain, organizations that aspire to be lean enterprises ignore this capability at their peril. It not only brings great product ideas to life, but it also determines the ultimate potential of your operational value streams.

In this month’s Design Brief, we will focus on the know-how behind making things well, which includes the skills of tool, mold, and fixture makers, special machine designers, manufacturing engineers, and everything that goes into truly knowing how to turn a concept into reality.

Of course, one of the key differences between lean product and process development (LPPD) and other approaches to development is that its goal is to create successful value streams, not just to create great new products.

That includes knowing how to make things in a way that keeps operators safe, minimizes waste, builds in quality, and creates flow. It also understands and protects key product attributes and accommodates product portfolio and volume flexibility without losing quality or efficiency.

The decisions made during development about design, process, layout, equipment, and tooling will impact operations for years to come. Once these things are decided, all the post-launch kaizen ideas in the world will have only a tiny fraction of the impact those same ideas could have had during development. In fact, much of what people think is kaizen is just rework.

Invaluable to design

While some designers I have worked with, especially more recently, see manufacturing process experts as impediments to their creativity, the best ones recognize that they are invaluable guides in exploring the art of the possible.

I recall a conversation I once had with Jony Ive, the uber-talented former lead designer for Apple. He talked about the invaluable relationship between the design studio, manufacturing, and tooling engineering. It turns out that he had invested a great deal of time in deeply understanding various materials and their limits, as well as the capability of manufacturing processes such as forming, coating, and machining to better partner with the people responsible for bringing his vision to reality.

Ive is one of only a few designers I’ve met who have a deep appreciation for knowing how

to make things; perhaps that is why he is also one of the very best. But to be successful, your up-front process experts must have the right experience and attitude. Their job is to figure out how to bring the design vision to life. Not just immediately reject every design idea that does not fall into a very narrow set of requirements. Creativity, deep expertise, and a passion for the product are essential in this role.

Partner with product engineers

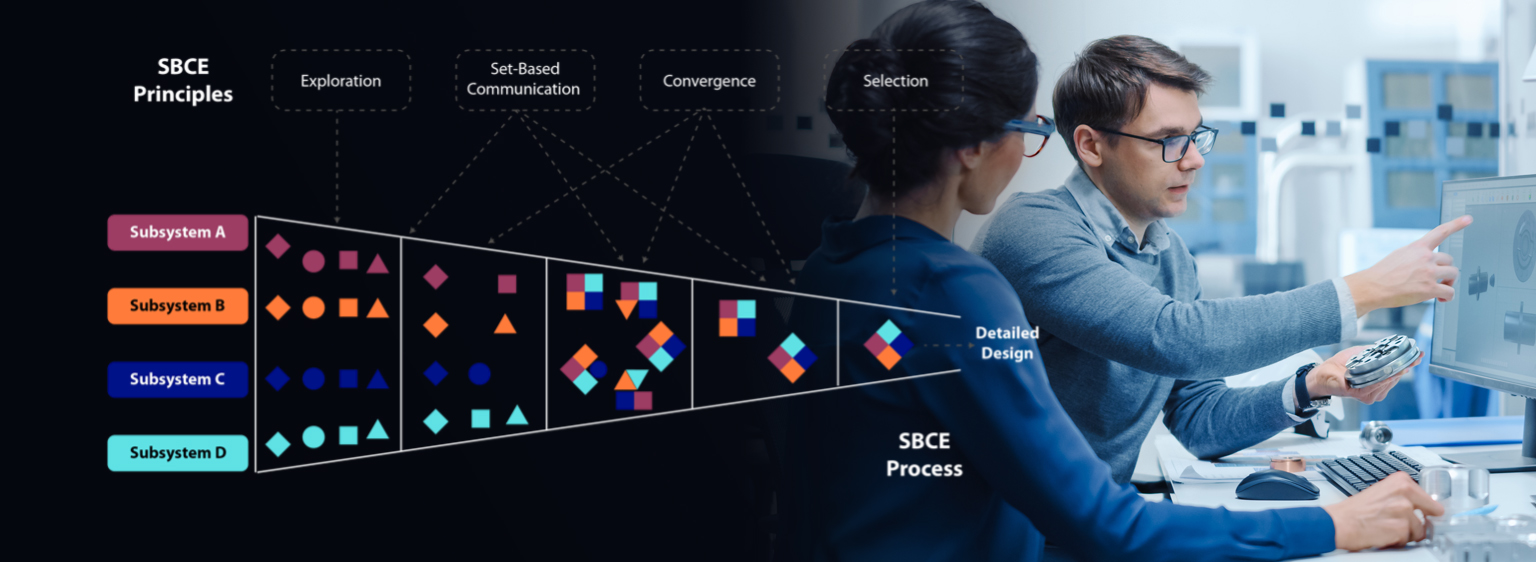

At least part of the reason we have maintained the admittedly awkward moniker of lean product and process development over the years is to demonstrate our commitment to the importance of product–process collaboration in development. This partnership begins from the start of development with set-based concurrent engineering (SBCE). SBCE exploration, experimentation, and deselection of alternatives must include manufacturability as a critical decision criterion.1

Unfortunately, in many companies “design for manufacturing” has become more of a slogan, or a vague sentiment rather than a rigorous, semi-structured discipline. And their difficult launches bear this out. That said, it is not the role of the up-front manufacturing expert

to simply reject creative engineering solutions; it is to be a true partner by bringing their knowledge and skills to bear to create outcomes.

To help with this process, LPPD proposes tools and methods that enable this collaboration.

It also offers a framework based on both progressive design maturity and manufacturing readiness levels that are built into milestones/integration points to orchestrate the team’s work.

Save you at launch

Production launch, especially of complex, sophisticated products, can be quite difficult. Some have even referred to it as “production hell.” While I haven’t experienced quite that level of discomfort, I have certainly been on my share of tough launches.

But the challenge of launch should not be a surprise. It is the first time that you bring together the tools, equipment, parts, processes, and people to run at production rates and quality. This is the point where complex system interactions have a troubling way of creating unexpected problems – in bunches. Toolmakers and process engineers are some of the best problem solvers I have ever worked with and are an integral part of any successful launch team. That can be much more difficult if those people are located on a different continent.

And beyond

The ability to consistently design and deliver successful new value streams is a hallmark of a lean enterprise and a powerful competitive advantage. Process engineers and tool makers are at the core of this capability and essential for delivering on quality, cost, and product performance simultaneously. But they are becoming as rare as they are important. Consequently, we strongly encourage you to invest in growing these skills and experience within your organization along with an operating framework that allows them to be successful. After all, the ability to create new value streams is far more important than any single product.

In this month’s Design Brief:

- LEI Senior Advisor John Shook examines the role of product and process development capability in the historic turnaround at NUMMI and shares some thoughts that might help Boeing, healthcare, and other industries.

- GE HealthCare’s Global Head of Lean Office Matt Zayko and LEI’s Senior Coach and LPPD Chief Engineer Eric Ethington share eight tips for creating great processes.

- Ben Armstrong, executive director of MIT’s Industrial Performance Center, talks with Matthew Savas and me about the current state of American industry and the challenges and opportunities that lie ahead.

- LEI founder Jim Womack shares a case study from a Lexus assembly plant that illustrates how synchronizing rigorous process development with product development results in high quality and low cost.

Download the latest issue of The Design Brief.

Designing the Future

An Introduction to Lean Product and Process Development.