As a long-time musician, I always enjoy hearing a great live show – especially at The Kessler in Dallas. This classic art deco theater opened in 1942, but remained largely vacant after a ’57 tornado and ‘62 fire devastated it. Thankfully, it was rebuilt a third time in 2010 as a music venue, and WOW, what a venue it is. It’s intimate, there isn’t a bad seat in the house, the staff is amazing, and there’s a magic that attracts diverse talent like St. Vincent, 10,000 Maniacs, and Jon Batiste.

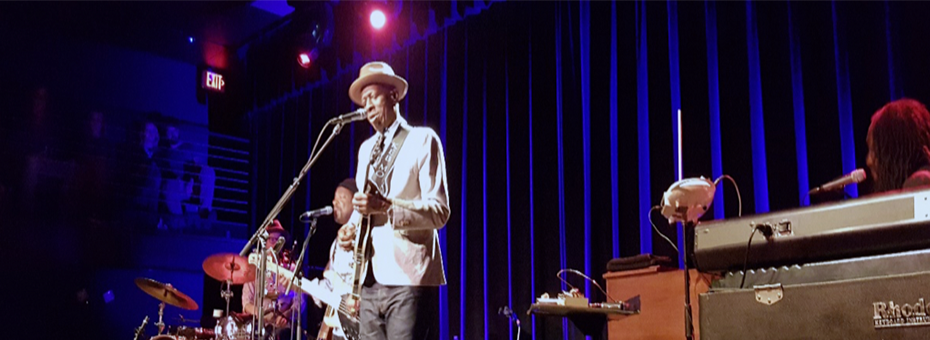

So when friends invited my wife and me to see blues legend Keb’ Mo’ there, we jumped at the chance. What I never expected, however, was it turning into a great live lesson about what most improvement programs overlook. No, Keb’ didn’t channel Taiichi Ohno through his Gretsch Electromatic, or pull the andon cord when the keyboardist missed a note: But without knowing a lick of formal lean, his ensemble delivered a powerful jam session on value. Here is what we learned:

Customers perceive value throughout the entire experience: Most organizations measure “customer satisfaction” under the belief that the product and price drive repeat purchase. Except it’s not that simple. 75% of repurchase is driven by the end-to-end experience – from branding and first contact through usage and support. Anybody can enjoy good Keb’ concerts for free on YouTube, but what made this live (and definitely not free) show special was the whole system of easy-to-buy tickets, friendly Kessler staff, good food & drink, great warm-up band, exceptional sound, meeting musicians after the show, plus being thanked on the way out. Value is never just envisioned in engineering and delivered by the factory, so how is your organization delivering customer-perceived value throughout the entire experience?

The show only runs smoothly when all stakeholders receive enough value: An often-overlooked facet of lean is “joint prosperity.” Happy customers are necessary for keeping an act afloat, but not sufficient for driving everyone involved to consistently deliver their best. If there isn’t enough value for each musician, crew, venue, vendor, equipment maker, agent, producer, studio, record company, promoter, and investor, the system falters when stakeholders leave for better opportunities. And as the music industry deftly demonstrates, it’s not just about money. Passion for the work, supporting a bigger purpose, and individual recognition (“Hey everyone, how ‘bout that awesome Casey Wasner on drums?!!!”) motivates many to forgo bigger, regular paychecks for long hours on the road. How is your organization insuring that all stakeholders receive enough value to keep the show running smoothly?

Focus on problems, but also connection and joy: The blues was created by Deep-South slaves and share-croppers during an era of extreme mental and physical hardship. And while lyrical references to pain and suffering are still standard in today’s blues, there is also an undeniable emotional uplift from sharing those challenges with each other. We are taught to relentlessly focus on problems, but is your organization also spending enough time increasing stakeholder value through connection and joy?

Nobody ever gripes that Keb’ should act more like Elvis: Musicians can teach us a lot about learning because they constantly improve through mixing theory, history, sharing, experimentation, technology, practice, and of course, feedback. And just like business, there is no universal formula or “best method” for increasing value and succeeding. A classical pianist may never write an original note, while others can advance avant-garde kazoo, or computer-automate Ariana Grande’s next hit. They don’t give Grammys to Elvis impersonators, so how is your organization learning from different sources (lean or otherwise) and then pushing beyond to create even more valuable solutions?

Humility and simplicity draw others in: I’ve met many blues musicians and lean experts in my life, and one difference is obvious: most blues musicians are humble (and many lean experts aren’t). People are drawn to humble musicians – wanting to hear their simple stories and participate in a new shared experience. And lean? Few relish complaints about those upstart rock ‘n roll kids or the unsophisticated masses who never come to the show. How is your organization drawing everyone into lean’s value with a humble, relevant narrative instead of driving them away with complexity and sour notes?

Sometimes less is more: A road show is a bit like setting up a uniquely-configured factory each night, running it for 3 hours, and then moving everything to a new location. Bands do a lot of leanish things (JIT, pull, visual management, error-proofing, cross-training, quick setup / changeover / take-down…), but Keb’ could have easily freed-up an extra song’s worth of lead time by standardizing the set list, better pre-tuning instruments, and not wasting time talking. Except that by blindly reducing “waste,” crowds would miss out on much more value. Audiences love hearing Keb’s stories while he makes his final guitar adjustments, and Keb’ loves reacting to their ever-evolving moods with banter and changing-up the song list, sound, and tempo. Every Keb’ Mo’ show is uniquely tailored and that’s part of the value.

Sadly, this reminded me of a company I know that used to be #1 in their market and a widely-recognized lean example. But over time, customers became dissatisfied with their products, delivery, and responsiveness, and they began losing money. Their solution? MORE LEAN!!! Or so they presumed…

More 5S, A3s, mapping, visual management, standard work, and Japanese terms only made operations worse, while overburdened employees kept stuffing the portfolio with more and more of the same failing products. The actual root cause was that they were so consumed with blindly reducing waste and “being lean” that they ironically no longer had enough skill or capacity to learn what customers actually needed – something completely different yet much simpler.

So until your organization can answer “What is value, really, and how do we create our own better path to getting there?”, take a cue from Keb’ – sometimes less lean is Mo’ lean.