A resilient, fast and profitable company. Employees committed to improve their work every day and happy to work with their colleagues and managers. Customers hooked and raving about your brand, lauding your flawless products and ultra-fast delivery. What is not to like?

You are sold. Now is the time to turn your company into one of those “lean” success stories. But how to proceed?

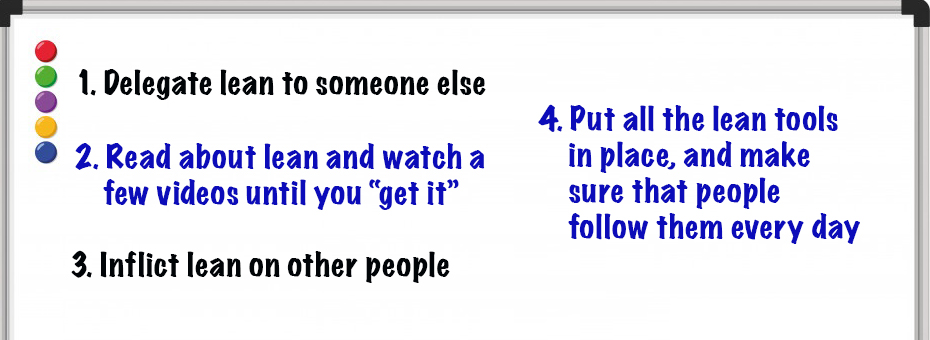

Let’s start with the easy part: failing. Failing at lean is quite easy, and a path that is well trodden. Here are a few proven tactics to save time and fail even faster.

Delegate lean to someone else

This is the best one. Find someone down the ladder, or a consultant, who has time for all this stuff, and ask for monthly reports to see how the lean initiative is going. When the initiative fizzles, as it will inevitably do, just use the time-tested, three-step playbook: complain about people’s reluctance to change, question the consultant’s skills and draft an action plan for the next initiative. Hopefully, no one will notice the pattern recurring over the years.

Read about lean and watch a few videos until you “get it”

Lean experts and CEOs say they hone their skills through years of deliberate practice, and they keep repeating that lean is just that: a practice. This might work for lean fanatics with too much time on their hands, but you have more pressing issues. After a couple hours skimming through the lean literature you realize that these principles are indeed quite easy to grasp. You have been doing lean for years without even knowing it! It will now become even more apparent that nothing is actually changing in your company precisely because the other managers fail to understand these basic principles. You definitely have some lecturing to do.

Inflict lean on other people

It is obvious that lean does not apply in your situation: your activities are so varied, and you only deal with intellectual and non-repetitive tasks. You soon notice however that your colleagues, whose work is without doubt much simpler than yours, could benefit from many lean improvements. What is surprising, however, is the extent to which they are not aware of all the inefficiencies in the way they approach their work. It is time to ask them the lean questions, so that they realize how misguided they are and embark on a journey of continuous learning.

Put all the lean tools in place, and make sure that people follow them every day

These tools are necessarily good, so the more you have in place, the better. The most advanced lean CEOs use only a few tools to focus on people development and business growth, but they must be leaving lots of potential improvements on the table. Make a habit of collecting as many tools as possible, and implement them all. You will soon observe that people lack the discipline to maintain everything all the time, but fortunately you have the answer in one of those “5S” practices: set up a solid reporting system and a strict cadence of management audits to ensure that tools are consistently used by all the teams over time. That should overcome their well-known resistance to change. Congratulations, you just replaced an old malfunctioning bureaucracy with a new malfunctioning one!

Moving forward

With all this tongue-in-cheek advice in the open, it’s time for an inconvenient truth: lean is indeed a practice, a personal journey. It is very much akin to mathematics, in the sense that it is a structured way to think about real world business situations. It is also similar to sports or music: fluency is the direct result of months and years of deliberate practice.

There is no shortcut. It is all about digging into customer complaints, analyzing defects, struggling with kanban, scratching your head at tricky kaizen challenges, and changing your mind about many great product ideas.

As you face these myriad problems, you will notice changes in your own thinking. You will start asking different questions, considering different alternatives. You will establish different relationships with your colleagues, customers and suppliers. And hopefully one day, while contemplating the amount of problems you still have to face, you will be surprised to learn that your company is the one others are trying to emulate.

(The author has just published the book Learning to Scale: The Secret to Growing a Fast and Resilient Company.)