Last week I had the good fortune to film John Shook explain LEI’s Transformation Model. This is the model LEI coaches use to guide lean transformations with our partner companies, large and small, across a wide range of industries.

About a year or so ago our mission here at LEI changed from “Advance lean thinking throughout the world” to “Make things better through lean thinking and practice”. I’m a huge fan of this change because so much of what we do here is about, quite simply, making things better. What better way to advance Lean than to show the difference it’s made in the world for people, organizations, and businesses? I firmly believe LEI’s Lean Transformation Model makes things better, whatever the industry. Or better yet, it helps people make things better for other people (employees and customers alike).

What I love about Shook’s explanation of LEI’s Transformation Model is that he makes it relatable without dumbing it down. Simplifying complex ideas is one of the hardest things to do.

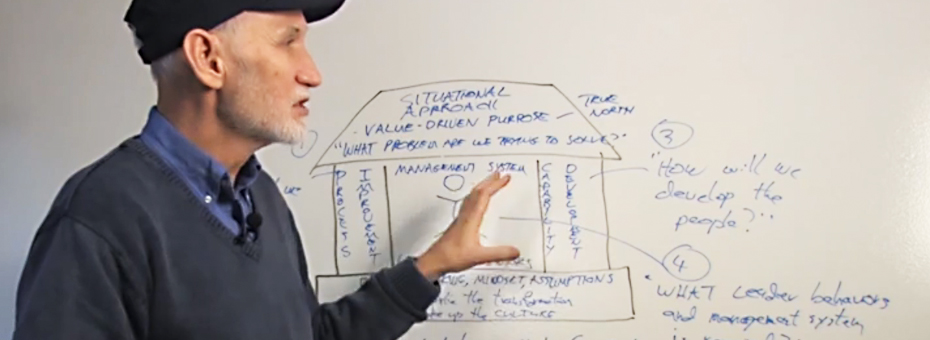

In his recent e-letter Shook offers the same 5 key questions for transformation:

- What is the purpose of the change–what true north and value are we providing, or simply: What problem are we trying to solve?

- How are we improving the actual work?

- How are we building capability?

- What leadership behaviors and management systems are required to support this new way of working?

- What basic thinking, mindset, or assumptions comprise the existing culture, and are we driving this transformation?

Interestingly, these are all questions we asked ourselves at LEI when developing our new mission.

Here’s a link to the e-letter by John Shook, and I highly recommend viewing the video below on the transformation model we use here at LEI. Its about 9 minutes long, so you may want to set aside some time to watch it, but it’s something I suspect the lean community will be learning from and sharing with each other (and making their own?) for years to come.

John Shook explains the Lean Transformation Model

I would like to know the lean framework for starting the program