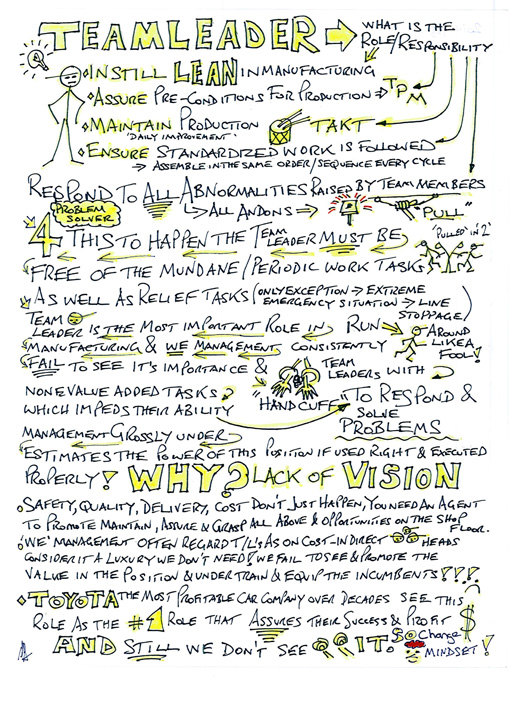

Change agents are key to making lean happen and making improvements stick. Yet the value of competent team leaders trained in basic lean techniques is grossly underestimated and underutilized by next-level management. Why do we, the management, underestimate that importance, you ask?

Change agents are key to making lean happen and making improvements stick. Yet the value of competent team leaders trained in basic lean techniques is grossly underestimated and underutilized by next-level management. Why do we, the management, underestimate that importance, you ask?

It’s a lack of vision, in my opinion. We often see the team leader as a luxury we don’t need; an overhead, indirect cost to be cut when the going gets tough.

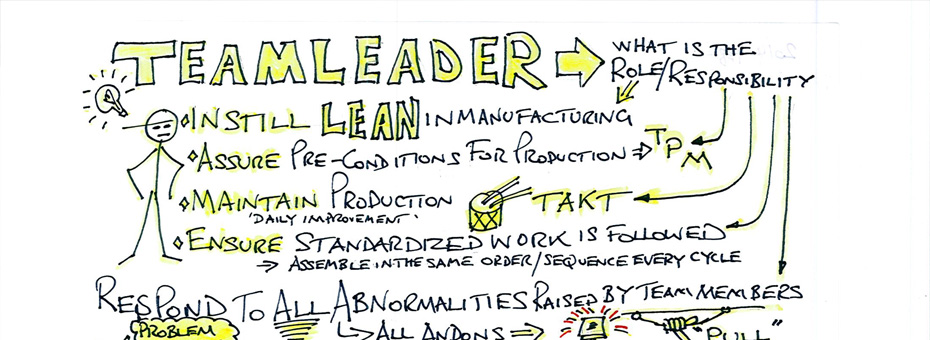

But that couldn’t be further from reality. The heartbeat of an effective TPS deployment is the role of the team leader, as you’ll see in my sketch. And if you need more proof, look straight to the bottom of the sketch for a real-life example of a company that uses team leaders to their full potential.

Now that you’ve seen the sketch, I ask you: has it helped change your view of the role of team leaders on the shop floor? It is the drumbeat (‘takt’) of your operation if used properly!