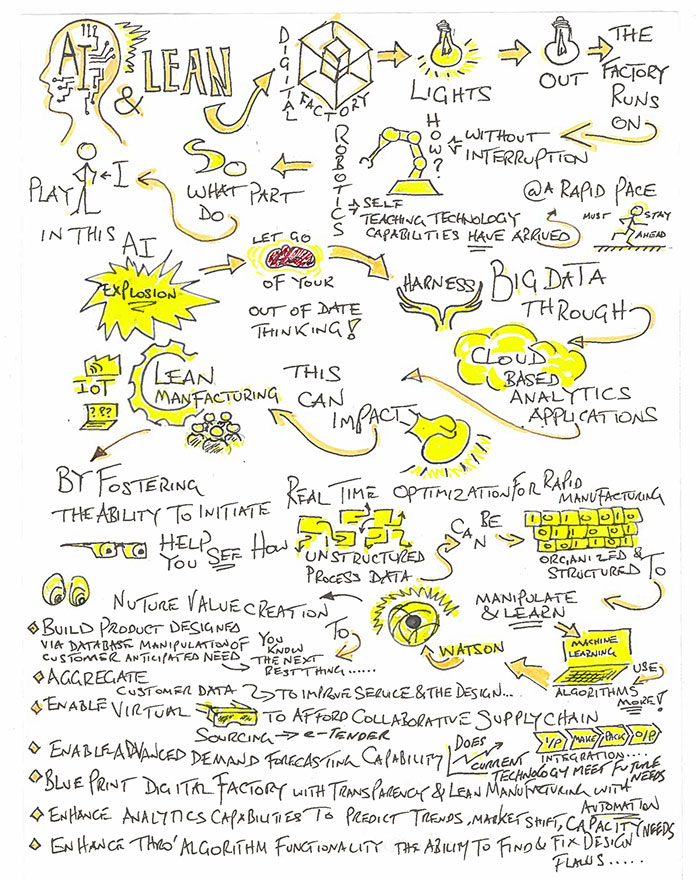

They have all really arrived but do you know the impact they are going to have on you? Within the next 10 years, I predict rapid re-modernization within manufacturing will occur due to the rapid integration, dare, I say, invasion of these three themes which could strive towards making the human more redundant on the shop floor as the digital factory takes over.

Digital factory; what you talking about?

Manufacturing can and will run with the lights ‘out’, advancements in robotics and automation are rapidly eliminating the human dependency out of the manufacturing processes, so the dependency will become negligible in the future. The Digital factory will be an environment where minimum human involvement will be needed as technologies will perpetually real-time optimize manufacturing processes self-learn to improve and ‘speed’, the processing of data and the manipulation of data will drive advancement at a phenomenal rate of change that we will not be able to hold back, but should strive to influence.

So what part can I or you play in surviving the AI explosion? What part do lean principles play? We have to let go of our out-dated thinking and in some respects take a leap of faith into the unknown to frame the vision for our businesses as to where the balance between technology and humans needs to sit, ensure our inclusion and prevent exclusion.

How?

Better use of the available data within your organization is a key factor in those businesses that are at the cutting edge of this technological advancement; learn how to manipulate the data better. Developing algorithms to find and dissect data is really driving the ability to predict and anticipate what we want — or don’t know we want yet –but we’ll be served up that option as AI believes this is a perceived need we will have to fulfill.

Most businesses only use a fraction of the benefit from the data they hold.

The capability to slice and dice the data into more meaningful chunks of useful facts to act upon is a wholly under-utilized muscle in many industrial sectors. Most businesses only use a fraction of the benefit from the data they hold. The trick is having the vision to see how you can manipulate the data you have already to frame tomorrow’s customer need and expectation beyond today’s norm. You must get off the carousel, stand back, and observe what’s going on and where is or is not the sector moving.

For me, who has not been all my life a ’tech-savvy,’ IT-driven individual, this has been hard. I have had to learn this to remain relevant tomorrow, especially as I work within the e-commerce sector now. But I do understand the game, the strategy, and the direction I need to follow to stay relevant for at least the time being. Being involved and influencing, yes, trying to influence, is my role, in order to help balance the case for and against the rate of change that AI and machine learning can take.

This cannot be stopped. It is inevitable and will happen so, as you cannot fight it, then help shape the benefit and the outcome.

For me, the areas where artificial intelligence (AI) machine learning (ML), and the internet of things (IoT) can have the greatest benefit are:

- Designing a better product as customer data has been manipulated to anticipate the next best thing they need (or don’t know they need as AI has anticipated they will want it).

- Aggregating customer data to improve service as the second step to the anticipated better-designed product.

- Virtual sourcing and developing a collaborative supply chain structure that rapidly advances e-tender virtual auctions with strategic and preferred supplier groups.

- Advancing forecast demand modeling — predictive and directional market trending analysis to identify what manufacturing technology you need to meet current or future product designs and customer anticipated needs.

- Blueprinting the digital factory by creating a very transparent view of operations, where minimal human involvement is needed or wanted in very fast and repetitive tasks; apply lean flow, pull, and optimized automation and robotic integration to run lights-out as needed. In essence, AI will design processes extracting pertinent lean principles as needed without human involvement.

- Enhancing analytics capabilities that are perpetually working to predict and anticipate market trend conditions; modeling and simulating the perceived need in order to have the internal capability and manufacturing capacity within your existing digital factory or extended supply chain (third-party fulfillment) to meet market needs should this need be realized as per the predictive modeling applied.

- Deploying self-learning and intuitive algorithms functionality to detect design flaws and fix them before the product is integrated into the hard manufacturing workflow where we start to add value, which can translate into waste of the design is wrong.

This is a lot to digest I guess?

I call it deep thinking to remain relevant in a technologically advancing world that threatens to make people redundant.

I would encourage all that read this article review my sketch to take a step into further understanding these very pertinent areas of our world tomorrow, that are shaping and will further shape our future whether we like it or not.

The Future of People at Work Symposium

Collaborating on the Challenges Ahead.