Why do lean transformations succeed or fail? Creating a culture where people think about continually removing waste, regardless of the current health or prosperity of a company, plays a key role, says Sammy Obara.

In his Lean Talk at the 2018 Transformation Summit, Sammy, who was born in Brazil to a Japanese family, started with potty talk. When he first went to Japan Sammy was struck by the way Japanese toilets included a visual element enabling users to save a gallon of water. Years later, after economic growth and a broader sense of prosperity, Sammy notes that this same practice exists—and that in fact many leading companies are producing toilets (some of which cost $1000 and up) that are still focused on conserving water (or, one could say reducing waste….)

Sammy notes that this approach reveals a crucial distinction in how to think about constant improvement. Instead of asking why anyone should continue to save that extra gallon, a more learning-based question might be: “why should anyone waste that extra gallon?”

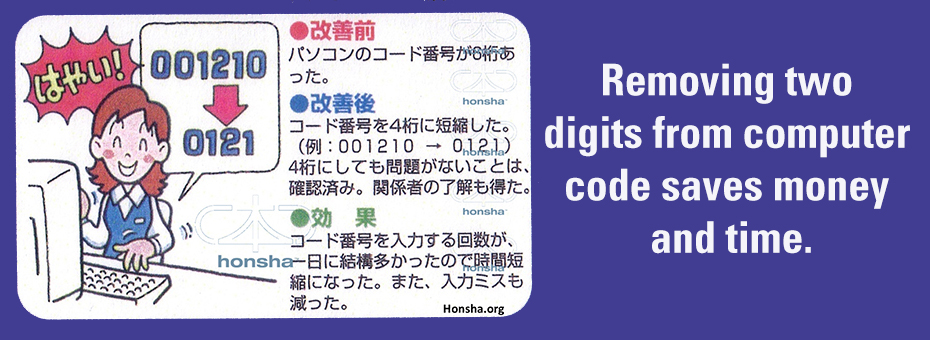

Working at Toyota Sammy saw the company work to save one second from a bureaucratic process by condensing a six digit code to four, potentially saving one second of work (and the possibility of errors and rework). Yet again he realized that the question was not “Why would a company that is almost $300B in revenue need to save one second?” but “Why would any company regardless of their size need to waste one second?”

Developing people to think in this different way is key, says Sammy, who asked:

“How can you make people change the way you think so that there is a learning platform?”

What to do next:

Keep developing you and your team members as key contributors to building a company culture of continuous improvement. Catch Sammy’s practical workshop and session at the 2020 Lean Summit, April 6-7, 2020, in Carlsbad, CA. Learn more about the Lean Summit content and how to save big on registration by clicking here now.