Fully grasp how lean thinking and practice transform operations, yielding workflows that require less human effort, less space, less capital, less material, and less time to make and deliver products and services to precise customer desires and with fewer defects.

Achieving efficient customer-focused workflows

Organizations whose operations are driven by lean thinking & practice achieve competitive advantage because they are based on a customer-first philosophy and fundamental market economics. These companies recognize that the marketplace ultimately determines the price of goods and services. They understand that, since customers determine the prices of goods and services, the best way to increase profitability is to lower costs. With this awareness, they reverse the traditional profit formula:

From: Price = Cost + Profit

To: Price – Cost = Profit

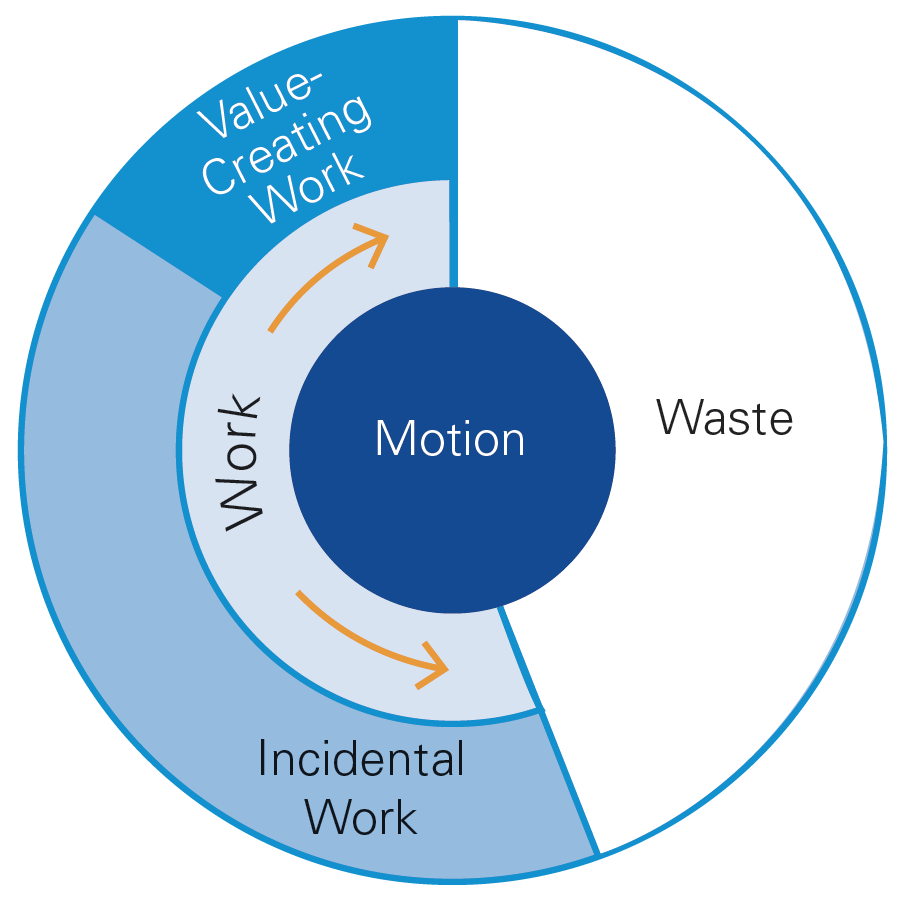

Fundamental to operations steeped in lean thinking and practice is an in-depth understanding of the specific work to be done, starting with the three categories:

- Value-Added – tasks that add value to a product or service

- Essential but nonvalue-added – activities that do not add value but must be done to complete the value-creating work

- Waste – any action that creates no value for the customer

These organizations relentlessly pursue the elimination of the seven major wastes:

- Overproduction

- Waiting

- Conveyance

- Processing

- Inventory

- Motion

- Correction

Operations based on lean thinking and practice also continually strive to achieve flow, in which material and information move through the value stream without stopping. When flow is not possible between process steps, each step in a value stream should “pull” precisely what it currently needs from the previous step in the value stream.

This “pull” then is the signal for the previous step to immediately make new items to exactly replace those just withdrawn. With this approach, organizations replace complex scheduling systems—which depend on the centralized accumulation of information and complicated formulae—with simple, intuitive processes that work much better while dramatically reducing the amount of inventory at each along a value stream.

By organizing operations to produce on-demand and deliver what the customer wants with increasing efficiency, the production and delivery of goods and services become a competitive advantage.

Relevant Events

September 17, 2025 | Plymouth, WI & Gainesville, FL

Lean Warehousing and Distribution Operations

Learn moreOctober 23, 2025 | Morgantown, PA