Change is hard – we all know that – and ignoring the element of respect for people makes engagement and lasting change practically impossible.

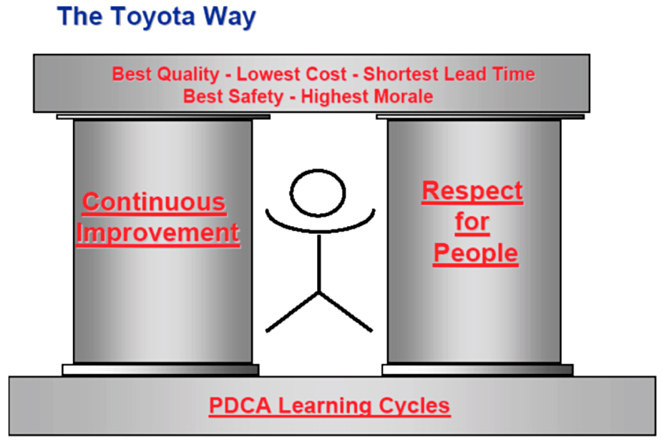

Most of us are familiar with the Toyota Production System House, with its two pillars of Kaizen and Jidoka, but the model that resonates more deeply with many is The Toyota Way House as you can see below. This is certainly the case for me, and I’ve been reflecting on why this is.

Here’s a thought: the Toyota Way model suggests a relationship between the technical and social sides of a lean transformation that we intuitively know to be true.

On the left side is continuous improvement or kaizen, and here where most people invest their time, learning, and experimenting with the myriad lean tools available: value stream mapping, 5s, A3, PDCA, standard work, visual management, kanban, heijunka, hoshin kanri, etc. These tools can be very effective at making a significant impact on safety, quality, delivery time, throughput, and productivity. However, most people discover that a tools-based approach to lean transformation is impossible to sustain and does not create anything approaching a lasting change for the better of people, teams, or organizations.

It’s really not surprising then that, according to McKinsey, 70% of all organizational improvement initiatives fail. This isn’t surprising considering the very few examples we have outside of Toyota of enterprise-wide lean transformations. There are many reasons why this is, but perhaps one key factor is that most organizations fail to intentionally balance the technical tools side with the social side of Lean. Most people say, “We respect our people. In fact, it is one of our core company values!” I don’t deny that most of us strongly believe in respect for people and that is great. But there is a big difference in believing in something and acting in a way that aligns with that belief.

On the right pillar is respect for people, so what does that really mean and what sort of actions can we take that shows we really practice respect for our people through the way we do our work? It comes down to this: how are we engaging our people? Is the purpose in peoples’ hearts aligned with our organization’s purpose? What specific behaviors are we taking to stand in the other person’s shoes and develop a deep awareness of their point of view? Do we try and try again to see the work from their perspective?

We spend so much effort trying to design perfect work systems and improve business processes focusing on lean tools, while simultaneously failing to connect with people on a level that awakens mutual trust, engagement, effective teamwork, and self-generating accountability (in other words accountability wherein people are intrinsically inspired – people assume accountability because they want to, now because they are being told to, measured, or threatened). A key takeaway from the illustration above is that creating a balance between the technical and social sides of Lean is not just good, it’s fundamental. It is the foundation upon which everything else rests. So, what are you doing in your organization to create this balance?

The next gemba walk you take, kaizen event you participate in, or daily stand up you attend, or A3 you review, ask yourself two questions:

- “What are we doing to show our people how much we care and how much we respect their opinions, ideas, contributions, and potential to transform?”

- “Are the actions we are taking to lead with respect fostering the levels of engagement, teamwork, and accountability needed to attain our vision and purpose?”

My hope is that as a lean community we raise our collective level of awareness of what effective leadership looks like and build a bridge connecting the tools side of Lean to the results and relationships side. We desperately need both to create deep and lasting transformation. Indeed it is only when we create an environment of mutual trust that we can change work habits and sustain high levels of performance.

Editor’s note: An earlier version of this article shared a statistic from McKinsey that 90% of organizational transformations fail without a holistic approach. This has been since been corrected, linking to a 2013 report.