The title of Pascal Dennis’s Getting the Right Things Done succinctly states the core promise of this popular guide: choosing and executing on the key strategic priorities for your organization. Since its 2006 publication, this detailed guide has guided tens of thousands of people select the right goals to pursue and then get them done. You can download excerpts and helpful forms from the book here.

This first part of a two-part series explains how strategy deployment (also known as hoshin kanri) ensures that lean is at the heart of your enterprise.

Within Toyota strategy deployment is known as hoshin kanri, the planning and execution system that has guided the development of the world’s most powerful production system. At Toyota Motor Manufacturing Canada plant in Cambridge, Ontario, strategy deployment steered us through the chaos and stress of continual expansion. In 10 years we grew from a cornfield to a 3,000-person company making 230,000 cars per year.

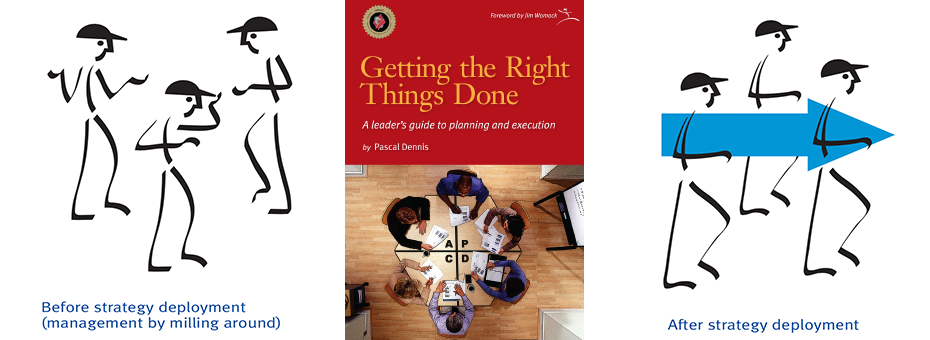

Strategy deployment will focus and align your activities, and allow you to respond quickly to threats and opportunities.

Remarkably, in Cambridge our safety, quality, cost, and throughput results kept improving, and we were showered with awards. The system kept us humble. “How can they give us an award?” we’d wonder. “We have so many problems.” It was quite a journey. Only now, years later, am I able to grasp what really happened, how we avoided catastrophe, and got so strong. It was my blind luck to work with a master trainer. (If you see this, Shin-san, I am in your debt.)

For many years, I have been the sensei, teaching the system outside Toyota, to both automotive and nonautomotive manufacturers, and to the process, service, and construction industries. Each implementation has deepened my understanding. What have I learned? Each company and sector is different, and most companies are not Toyota. We must tailor the planning and execution system to fit the business as it is, warts and all.

But why should you care? Well, strategy deployment will focus and align your activities, and allow you to respond quickly to threats and opportunities. Moreover, it’s a human system. People respond because it acknowledges their individuality. With strategy deployment, we don’t tell—we ask questions. We don’t command—we engage. Our people are not human resources—they’re human resources. Most important, we try not to bore with meaningless data—we try to tell interesting stories.

Use Strategy deployment (Hoshin Kanri) to Keep Lean at the Heart of Your Enterprise

Strategy deployment is the antithesis to “command and control,” still our predominant mental model. Command and control can suck the zest and meaning out of work. Insidious, it lives in the minds of supervisors, managers, and executives. Once we’re promoted, we think our job is telling people what to do. “Very strange,” my sensei once said. “In North America you manage business the way the Soviets managed their economy.”

If you’re a manufacturer facing low-cost global producers or other company-killing threats, strategy deployment can save the jobs that sustain your community. These days, manufacturers have little room for error.

But maybe you’re not a manufacturer. Maybe you’re a service provider, a software developer, a bank, a hospital, an insurance company. The storms are no less threatening. You might be facing your own challenges. Jobs that seemed secure just a few years ago are melting away—customer service, software development, engineering, research and development, and accounting jobs.

Strategy deployment ensures that lean is aimed at the heart of the enterprise. Lean thinking begins by defining value—what’s important to. the customer. If lean serves the core needs of the customer—safety, quality, delivery, and cost—and is introduced at the highest levels of the organization, it’s forever. By contrast, if lean is peripheral or introduced at lower organizational levels, it’ll have a limited half-life—a major loss, given the exceptional track record of lean thinking.

Strategy deployment ensures that lean is aimed at the heart of the enterprise.

Strategy deployment can also keep lean practitioners focused on the prize—creating value for the customer. Sometimes we forget that the elegant lean tools—value-stream mapping, standardized work, pull systems, and so on—are means to this end, and not ends in themselves.

Our improvement paradigm remains:

- Stabilize

- Flow

- Pull, and

- Improve the system (seek perfection).

Ensure Effective Deployment By Engaging Your Team Members

Our engine is strategy deployment, through which we align, focus, and engage our team members. But unlike conventional planning systems, our emphasis is deployment—not selection—and deployment is difficult.

Getting the Right Things Done is intended for leaders at all levels and across all industries—from CEOs to frontline team leaders—and will help answer the following questions about deployment:

- What are the nuts and bolts of strategy deployment?

- What does an implementation look and feel like?

- What are the underlying mental models and how are they different?

- What kind of management is required?

I’ve tried to describe how strategy deployment might be implemented in a manufacturing plant. It could just as easily have been a hospital, laboratory, or an insurance company. Experience has taught me that there is no one best way. It all depends on the need. Think of it as customized standardized work.

Japanese is a metaphorical language. Hoshin kanri has several meanings, including “shiny metal” and “compass.” My favorite is “ship in a storm going in the right direction.” We’re all in the deep water now, and the storm is raging. The waters may get even rougher. But there is a better way to navigate. Having a sensei certainly helps, but you may not have one. I hope that Getting the Right Things Done, and its protagonist, John Karras, can fill that role.

Hoshin Kanri

Aligning and Executing on Your Organizational Objectives.