Ideally a portion of everyone’s work day involves striving for something meaningful that we call a “challenge.” In business, a challenge typically means better serving customers. A challenge flexes our minds because it brings us to the current limit of our thinking and forces us to learn and adapt. But here’s the thing: it’s not enough to simply set a challenge. We need effective ways of working toward challenges! I know it sounds simple, but it isn’t.

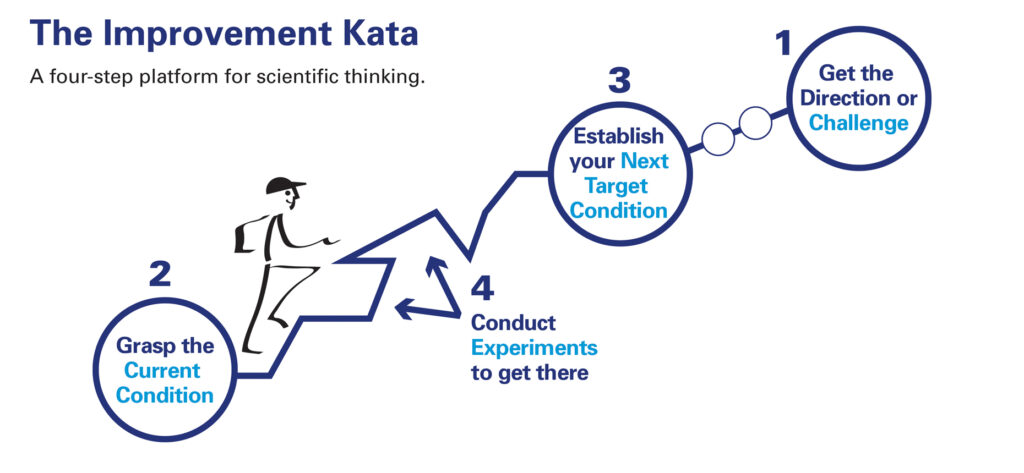

The Improvement Kata is a systematic, scientific routine for moving from the current situation to a target situation (condition) in a creative, structured, and meaningful way. Rather than a program, it is a pattern—a pattern people can practice and learn in order to achieve new things they don’t know exactly how they are going to achieve.

The Improvement Kata pattern begins with a sense of direction, or a challenge. The challenge statement is extremely important because it’s difficult for people to stay engaged with improvement efforts that aren’t rooted in an inspiring purpose.

To identify purpose, we must first consider, “What is a challenge, anyway?” A challenge is a theme that connects organizational strategy with process-level execution. The task for leaders then is to establish specific challenges (or themes) that guide and inform the application of the improvement kata pattern. This typically means strengthening the organization’s existing product or service capabilities or developing new capabilities as necessary to meet customer needs. A challenge is a non-negotiable goal and meaningful description of a new level of performance that will distinguish your organization from its competitors.

One point to note here is that “efficiency” or “cost cutting” are not challenge statements or useful themes, nor do they constitute a strategic direction. Just pursuing low cost is unlikely to be a source of sustained competitive advantage and growth. This often leads companies into a commodity trap where, in order to compete, you pursue ever-lower-cost inputs and end up jeopardizing quality.

Rather than managing the operational side of the business simply to be efficient, the improvement kata approach helps managers guide activities that support a strategic purpose that grows and differentiates the business (which may include efficiency, of course). Defining a vision or strategic purpose is about building unique value (i.e., distinctive differences that mean something to customers). This provides qualitative directional guidance for improvement efforts within the organization.

Once you identify a good challenge, that challenge will guide every day’s work. Without it, the following happens:

- The organization fails to work in alignment. Improvement efforts and proposals get ROI-evaluated independently, instead of as part of reaching for something. We tend to use short-term cost/benefit analysis to choose what steps to take, which keeps us dangerously inside our current knowledge threshold.

- We jump from one direction to another trying to avoid obstacles, rather than struggling through obstacles toward innovation and new competencies.

- What we call improvement is really just reacting to problems (“troubleshooting” to maintain the status quo) rather than reaching for a new level of performance.

How do you identify a good challenge? Specific challenges shouldn’t be easy, but they should be achievable. They should include stretch goals, in a timeframe from 6 months to 2 years. This way improvement kata teams can iterate toward successive target conditions. It’s a business “must” that the organization can’t achieve with its current systems or processes, and it needs to be defined by persons with value-stream responsibility. Remember, a challenge is best articulated by a punchy “challenge statement”, plus a future-state value stream map that shows the people where the organization is trying to go.

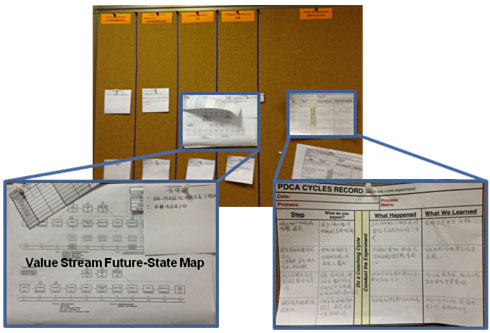

Future-state value stream mapping is a useful tool for the first step of improvement kata, because the value stream future-state describes in a graphic format, even universal “lean language”, how you want a value stream to function in 1-3 years. From the future-state value stream map we can define challenges and coordinated activities necessary to establish target conditions at the individual process-level inside value streams.

In the sense of Strategic Planning and Execution, value stream mapping is applied at the value stream level in order to grasp the current value stream condition and then design the future-state condition (the future-state condition that serves as a challenge for the loops and processes along that value stream). Then the improvement kata and coaching kata get applied at the process-level in order to iteratively achieve successive target conditions toward your future-state goal.

So, let’s look at this in practice. In the following example, we find a visual example of this application in which an organization uses a value stream map to establish and communicate their challenge for reducing the total lead time of a service process. On the right hand side you can see the short PDCA cycles (routine for improvement kata) carried out in order to move toward that goal. Here’s what’s different about this plan. In a traditional approach to problem solving, people usually define a “fixed” action plan upfront hoping that by implementing it, they’ll meet their challenge and achieve their goals. The reality is completely different. With improvement kata, each step (PCDA cycle) is built up on the previous one and followed by a coaching cycle. This approach is all about daily experimentation and learning. And the interval between one step and another is relatively short (daily for short cycle-time operations or 2-3 times weekly for long cycle-time operations).

Meeting a challenge like this requires senior and middle management passion, engagement, and commitment from start to finish, from strategic planning down to the execution of daily work at the process-level and coaching. Otherwise, The Improvement Kata approach will remain “nice talk” and never create real change or lead to any lasting improvements.

Have you tried The Improvement Kata approach? How do you connect your future-state value stream map with your daily activities?

Improvement Kata/Coaching Kata

Develop Scientific Thinking, a Foundation of Lean Management in the 21st Century.