At HP Tronic, a contract electronics manufacturing organization in Sweden, we’ve been practicing Lean in our manufacturing areas since 2007. In that time we’ve also made a few efforts to introduce lean thinking in our administrative processes.Until recently, we’d never been successful.

For years we tried to find situations where we could apply “the lean toolbox,” but this of course was harder in administrative areas, and we noticed that any gains we made seemed to slip back after a couple of weeks. We weren’t able create real commitment, which we know now was because we didn’t have a clear connection between the toolbox and what we as a company were trying to achieve. Our efforts were focused on eliminating waste, almost randomly, with no clear target.

Then in February 2014 we were introduced to the Improvement Kata and Coaching Kata practice routines, as a part of a project with Produktionslyftet, a national business development program in Sweden to help manufacturing companies improve their competitiveness based on lean principles. These routines combine a pattern of scientific thinking with principles of deliberate practice, to make scientific thinking something anyone can learn.

This Kata approach was and is quite different from anything we’ve done before. For leaders, instead of having us focus on any kind of toolbox, Kata had us focus on defining a “Challenge” and “Target Condition”, and provided a clear procedure of iterative experiments to work toward both. It’s an approach that can be applied in any situation and practiced again and again. It was key to successfully introducing lean principles in our administrative processes. We identified a clear organizational challenge statement and then worked together to find out exactly what would be required for us to meet that challenge.

Here’s more of what we actually did to change our mindset and develop new skills.

The Role of Structured Practice

Our management team, with the assistance of a lean coach from Produktionslyftet, defined a 3-year Challenge: Production volume 50% higher with the same personnel and floor space. We started our KATA work in four areas: Sales, Purchasing, Engineering, and a joint group that we call the Quotation process (which includes Sales, Purchasing and Engineering).

Since the start we’ve conducted approximately 150 experiments and have achieved several Target Conditions on the way to the overall Challenge. We are following the experiments daily using coaching cycles with the Five Coaching Kata Questions. Our coach, Lars Danielsson, reminds us that coaching cycles are where scientific routine gets established in our minds as a habit. Coaching cycles help teach and instill the Improvement Kata pattern, both in the mind of the Learner and the Coach.

“When you hear the idea of improvement activities every day it’s easy to be reluctant, I was. But when you start to experiment and see the results, you get it. Before we started KATA, I believed a 2-hour meeting was better than a couple of 10-minute meetings. Today, after three months with experiments I’ve clearly changed my mind.” – Emil, Sales Manager

As a budding Kata Coach myself, in the beginning it felt odd to repeatedly ask the same questions of my team members, but the more experience you gain, the more you understand the importance of the structured coaching routine. The purpose of the routine gets clearer over time. It’s a standardized way of reminding yourself and the team of the target condition. It keeps you and your team on track so you don’t lose focus and start with experiments that really aren’t relevant for your current target condition. The Five Coaching Kata Questions help you be more efficient, focusing on what you learned from the last experiment and your next step (rather than entering a never-ending discussion of possible solutions).

Perhaps the most important thing about Improvement Kata is that while we are working on real goals, we are practicing.

The Improvement Activity

In our quotation process, we defined a Target Condition that described a work flow process with increased integration between the involved departments, and an outcome metric of 85% RFQs complete within standard time. To increase the integration between departments we started to experiment with ways to visualize the process. The work with this target condition resulted in a daily seven-minute meeting, a whiteboard visualizing the flow, and a set meeting agenda. Everyone involved agrees that they now have much clearer picture of what’s going on. Positive crosstalk between the groups has also increased. The rate of achieving the standard lead time has increased from an average of 60 % to 85% (May 2014) and 90% (June 2014).

“Before we started experimenting toward this target condition, there were countless complaints of lacking resources and the involved departments didn’t hesitate to blame each other. After the target condition was met, I haven’t heard any complaints and we are finally working as one group instead of three different departments.” – Veronica, Plant Manager

Combined with the work we’ve done toward Target Conditions in Sales, Purchasing, and Engineering, we’re now able to measure the throughput time, quality, and resource allocation through the entire quotation process (defined as “when we receive the RFQ until we deliver the quotation to the customer”).

The interesting thing, and the thing to remember, is that this improvement was developed out of a real and specific need. We worked toward improving the process through the pattern of the Improvement Kata, not something we benchmarked from someone else and tried to copy.

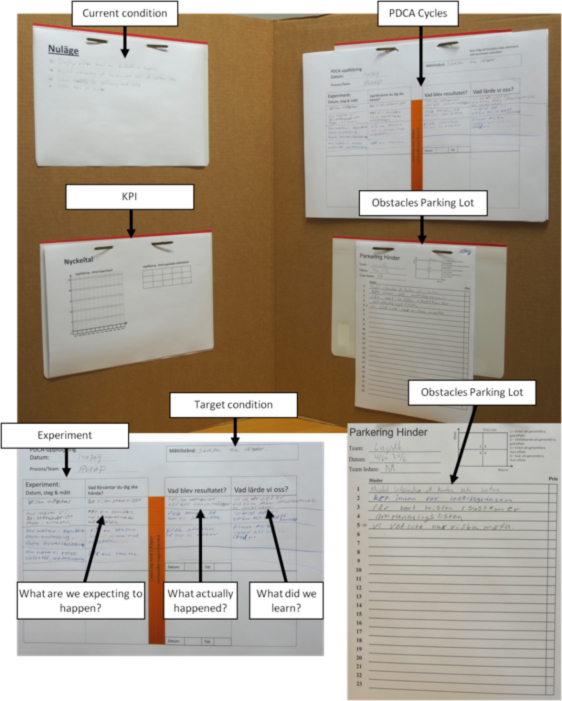

The normal elements of a Learner’s Kata storyboard. This one is in the Sales department.

Kata Lessons Learned

We’ve had our share of difficulty with Kata. First, there are a lot of areas where you simply have to change your mindset. For example, we had always worked on improvement projects with a clear start and end time. We talked about continuous improvements, but never understood what that meant in practice. The idea that improvement isn’t something you can take a break from was a huge mindset change. This challenged us to change our assumptions about what continuous improvement means and how work gets done. It’s still something we work on every day as it’s very easy to fall back into old habits.

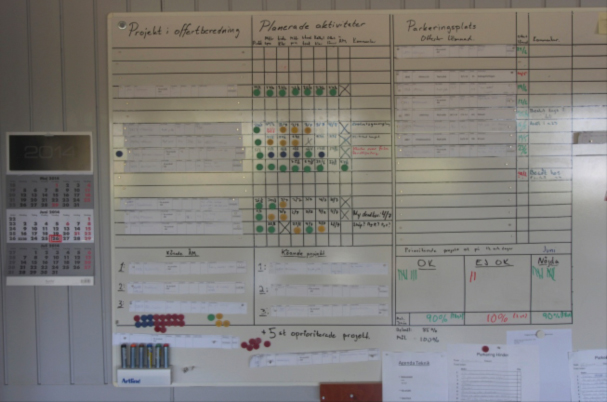

The whiteboard visualizing the quotation process that our Kata team developed.

Sales, Engineering, and Purchasing meet here every day at 08:30.

Second, before we started to work with Kata we had always focused our improvements activities by picking the lowest hanging fruit with no clear direction. The Kata approach is different; you have define a Target Condition and focus on the improvements needed to achieve it. Again, it’s easy here to fall back to old habits, especially when you try to experiment against obstacles that are hard to understand and overcome.

“Today I have much better understanding of the sales process, my colleagues’ work, and why we make certain priorities.” – Lars, Sales

Lastly, it’s hard to learn how to formulate good Target Conditions! You have to formulate a Target Condition that’s outside your current knowledge threshold, without using verbs (as if you were already there), and you have to make it concrete enough so you and your team know when you’ve reached it. (You’re defining where you are going without knowing how you will get there).

Next Steps

We’re still in the early steps of practicing Kata, but in the future we want this to be a part of our orgnanizational DNA. So as for the future, our main focus interestingly is “more of the same.”

- Create a habit of daily experiments. Try not to fall back into old habits.

- Experiment with ways to follow up our improvement activities in the management team, expanding Kata to other departments, and developing more Kata coaches.

- Create patterns of activity and learning throughout the organization so that this new way of working with Coaching Kata and Improvement Kata becomes normal.

If we’re successful, then we think HP Tronic can meet all sorts of challenges… with the help of “structured experiments into the unknown!”