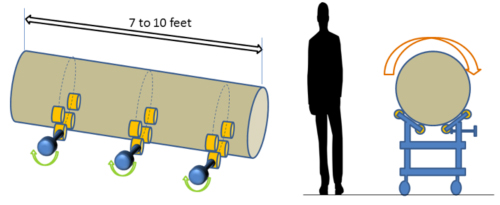

Recently, while visiting a client, a lean manager showed me an “improvement” during a shop floor tour. It was a workbench designed by engineers where a huge steel cylinder sitting on polyurethane rollers could be easily rotated by hand. Before this improvement, the steel cylinder had been laying on two or three steel trestles and needed to be moved with a traveling crane. The team had difficulty moving it.

The manager wanted to show me how easy it was now to rotate the cylinder. To do this, he said he had to release 3 or 4 roller brakes by rotating 3 or 4 handles anti-clockwise for 4 or 5 turns, which took some time. To his surprise, it was still proving difficult to rotate the cylinder properly. The lean manager told me, “I have to push too hard to rotate the cylinder. There must be a brake not fully released.” Then we went on the rest of our tour.

This moment in our tour got me thinking about what it takes to solve problems like this one, whether it’s on the shop floor or anywhere else. Kaizen Teian (or kaizen suggestions) is about creating a discipline of everyday kaizen in which improvements are made by frontline workers and operators themselves. For this culture to take root, team leaders must teach operators to go through three “gates”:

- Identify the problem

- Find root cause

- Fix root cause

This isn’t rocket science, but it’s not easy either. If you never teach team leaders these skills, kaizen will never happen in your company. It takes time to develop awareness and “5-why” thinking among team leaders and operators.

To help people go through these 3 gates, there are some lean tools that can help. Let’s look at the situation of the brake release. To properly identify the problem, try these lean tools to guide your thinking:

- Explore the 7 wastes. You have to admit for yourself that “It takes too long to UNSCREW the rollers brakes”, and the word “unscrew” is a clue among many other words of OVERPROCESSING.

- Use a spaghetti diagram. You can draw the walk of the operator from one handle to the other and show the MOVEMENTS around the cylinder, another well-known waste.

- Check if it is “right the first time.” You have to admit that the process of releasing the brakes is NOT RIGHT THE FIRST TIME, EVERYTIME: “I have to push too hard. There must be a brake not fully released”. So this process is badly designed.

Next, let’s go through the first gate and state the problem. Perhaps you say, “Releasing the brakes takes too long and it is tricky.” Now we can go through the 2nd gate and find the root cause:

|

? |

Releasing the brakes is long |

? |

|

Why |

Need to rotate 3 brakes handles for 3 or 4 turns |

Therefore |

|

|

|

|

|

? |

Releasing the brakes is tricky |

? |

|

Why |

The operator can’t see if the brake is released if he doesn’t bend to look at the roller and brake (3 times) |

Therefore |

|

Why |

Released position is not shown by the handles |

Therefore |

Only now can we design and implement a new solution. Again, some lean principles can help here. (Remember, you want to use lean tools and principles to help you or your team member find a better way to do the job, not just for the sake of using them).

Consider your options:

- Combine: Release the 3 brakes at the same time.

- Reduce or Eliminate. For example, reduce or eliminate the need to turn a screw for 3 turns to brake a roller.

- Change: Use foot to operate the brakes instead of hands.

Notice, the focus is on what the worker him/herself can do to improve the job. The focus is on the ingenuity of the worker who is drawn to actually build his/her solution, improvement, or next step. In a manufacturing setting, team leaders have to develop these skills for themselves, under the guidance of group leaders. With the right teaching and guidance, a good process, and a target of one kaizen activity per day, team leaders should develop these skills fast. They can then help operators to develop these skills. If needed, some low cost incentives can help develop this kind of problem solving culture, too.

It is by helping your people to develop their skills that you’ll be successful managers, with your entire workforce doing one kaizen per day. Just imagine how quickly those improvement activities add up.

In the end, this company that had a problem with the cylinder figured out how to solve the problem. The engineering and lean team did a great job improving the cylinder layout and rotation. Safety and ergonomics were taken into account. But the real learning point in this story is about the need to develop the skills of frontline operators so they become “improvers” rather than resort to saying, “Engineering always designs bad tooling.” The goal is to develop a kaizen culture among people, teaching frontline workers to improve the work by trial and error.