Anna, a Team Member on the Truck Assembly final line, notices herself falling behind.

It is 1994, and Anna is at the New United Motor manufacturing plant in Fremont CA, having begun her shift at rear seat and inner door install. Anna reads specs from the manifest, retrieves parts, and places three large seat pieces in the extended cab (and door parts) and two seats in the regular cab, as they pass her on a moving line traveling at a 90-second takt time per truck.

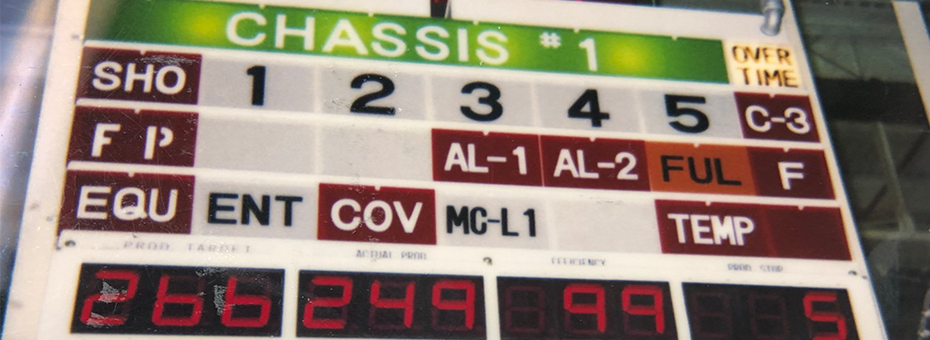

She is not working within takt time. There are visual hash marks on the floor saying what work is done by when, so you know when to pull cord for help. What starts to really concern her is the sales mix: One large extended cab after another comes down the line. Initially the job was set up for several regular trucks, followed by an extended cab. In this normal scenario she would gain time on the regular trucks and then use the time-savings up on the longer cycle extended cab. Today the mix coming down the line is mostly extended cabs.

Bob was no beginner and had been through the traditional labor wars and complex labor contracts. He had learned that there was a better way to resolve conflict – that the NUMMI non-adversarial “go fix it with the process owners” method was the better way.Anna finds herself pulling the Andon cord almost immediately because she could not complete the job in a 90-second Takt Time and she knows not to let bad quality go down the line. However when she pulls the Andon cord no one arrives. The line is down, and she has to finish the job and restart the line. No one is free to help.The reality is that injuries, vacations, people on leaves of absence, have caused all team leaders and even the group leader to be on line doing jobs that evening.

Anna understood the NUMMI system that works really well to identify, respond, unearth, and fix challenges. The system was going to do just that this evening. But on this night on this job it was going to take an outside intervention from the Union and Labor Relations to make that assist.

Anna put in a Union call to get help for herself (and her team) with the Labor Relations department to help resolve this overload issue. Under the NUMMI contract, challenges are handled at the lowest level to ensure involvement of the process owners. The call to Labor relations dispatched a UAW Rep and a Labor Rep.

Anna’s call drew UAW Rep Bob (25 years of experience, team member & TL experience) and Labor Rep Jeff (truck TL and Supervisor experience). Upon arriving at the line and being informed that Anna, her team leader, and group leader could not meet with them due to a Friday night attendance issue, we (Bob and myself) zipped right over to the job Anna was performing and observed 3-4 job cycles.

Bob was no beginner and had been through the traditional labor wars and complex labor contracts. He had learned that there was a better way to resolve conflict – that the NUMMI non-adversarial “go fix it with the process owners” method was the better way. In the past, grievances were written, problems left unresolved, and arbitration and much bargaining took place—i.e. deals. Bob was an experienced UAW man and had a big heart. This evening would bring his best leadership skills to the test as a teacher. I had a relatively open mind with only 7 years in industry and was learning from Bob.

Though both of us had been team members like Anna, we understood that each job, as a unique hands-on experience, is different. Both of us had shot bolts, attached parts, pulled the cord when needing help, and dug ourselves and others out of the hole (behind condition) many times. So like many other NUMMI members with lots of time on hand we could find true countermeasures to reasons causing bottlenecks to Takt Time. Seeing Anna struggling physically and emotionally with her very real-time overloaded job situation caused both of us a great deal of concern.

Our trained intent or automatic response (habit) to Anna’s struggle was to reserve any judgment, without criticism, to stay calm, and speak and act only in a way that brought resolution as best we could.

We knew right away that to help Anna she needed to be participating in the fight actively and not remain in a passive state taking blows from the overloaded condition of work. Any meaningful resolution was not going to happen unless she was physically safe/comfortable and emotionally calm.

Before both of us jumped on the job to free Anna up as a trained Observer, Bob made the odd comment to me “The job is light (not loaded to full potential in a practical way).” After seeing Anna struggle over three job cycles I thought Bob may have been pulling my leg (but I trusted Bobs’ experienced insight). I could see she was moving way too much and the net work was very low.

The two of us took over the job from Anna: I was retrieving parts/reading the manifest, and doing some door work part attachment, Bob was busy installing rear seats and torqueing them into place. Anna was asked to just step back and relax but keep us from sending a wave of bad stuff down the line.

Bob and I realized that leadership begins within with ones own self. Here and now this meant staying out of her way to allow Anna to master her challenge at hand. We helped when needed and tried to hold that job while she busted a move on the waste in record time.Anna’s blood pressure started dropping back to normal, her tears dried up, and she started to laugh a little watching us two knuckleheads have at it. However, something else was happening. Anna began to see what was wrong with the job—75% of the job was walking and recalling info. For the first time, she, as the process owner/real expert on the job, was free to just take a look and observe us moving and working. In this rare moment, unchained from the intense struggle, she was free to think. SHE WAS FREE TO THINK.

Anna (per her NUMMI training) grabbed a pen and a piece of cardboard and drew the walk paths and work times; a picture of the takt cycle. She went to her team room for shop floor tape and a ball of string. That act made Bob well up a little, and I was touched as well. We were delighted to see her strengths play out. Lets face it: some muda-busting was going to happen. Bob and myself both knew at that moment the tide had turned.

Anna used some string from the team room to measure the distance of walk angles between a part/tool location and the vehicle on the line. We were just helping by holding the job without falling in the hole, doing what looked like an iron man contest. All three of us could easily see and feel the causes of the existing waste of walk and reach.

Anna wasted no time in moving parts and tools around, and having us try this and that until it looked right and took far less time to do each task in the job work sequence.

Anna would race off to get a conveyance driver to ask if part locations could be changed, she asked maintenance to move tools and foolproof device zones. She grabbed a larger maintenance pouch to hold fasteners and clips and stuck it on Bob (I got a kick out of that).

Anna DID ALL THIS HERSELF. She felt empowered and knew it was a team member’s responsibility to set up their own Standardized Work routine to a Takt Time and to change the method when needed.

Bob and I realized that leadership begins within with ones own self. Here and now this meant staying out of her way to allow Anna to master her challenge at hand. We helped when needed and tried to hold that job while she busted a move on the waste in record time.

Two hours had passed since we leaped into the fire and lunch was approaching. Anna suggested we could help fix/try her ideas with conveyance and maintenance after lunch. We all agreed that “all of us” would do the new job work sequence together until Anna had complete rhythmical control of the work under or at takt time for the high cycle time extended cab. We shared the work for an hour after lunch until Anna was coasting with good quality and few andon pulls.

Anna was trained by NUMMI to identify and solve challenges via experiment with her team. She had been trained to set up jobs, build racks for parts, make line dollies to reduce walk, knew andon procedures, and job training principles for people.

Yet evidently what she needed to resolve the issue at hand was a little practical understanding/physical help and space to think while being relaxed and not being emotionally wound up. She needed extracted from the situation temporarily to just survive. Her deep focus took over to bring her best game. Best game it was.

The question is really “How do we allow people to create a new or extend a culture in those moments that ensure a better way forward?” “What leadership skill needs developed within ourselves to allow this to happen?” Respect for others abilities stands out near the top of the list, as well as the resolve to help them use their training to make that difference.

We knew Anna was the expert on the job. She needed “our resolve” to free her up and encourage her. Anna took almost immediate action to understand, discern a course of action, and to try a plan to solve a 30 second delay in takt time per job.

The next day we spoke with the manager, assistant manager, team leader, and group leader to set up a temporary countermeasure of learning from the previous night. Production control was given jobs in the shop close to being at a bottleneck condition when sales mix changed and a group gathering would happen when this was foreseen. Adjustments on job assignments would follow.

Anna and her team shared her learning on effective job design to minimize human motion in a 10-minute class for the shop teams “on the line” not at a board. True countermeasures were going to take place, but rarely can these be just done on a whim in the moment (though we can try). However in the critical moment her training kicked in to call for help, help came, and her determined focus transformed waste into effective work and open time. Anna demonstrated the NUMMI approach embedded in the heart of its team members.

I later asked Bob how he knew the job was light. Bob said he counted her foot steps and the angle/turns she made each job cycle. Almost three-quarters of Takt was walk.

None of the objects she needed were at the point of use to do the work. Why? We are only human, we make mistakes, but we can fail fast and learn to remedy the situation and not repeat the same mistakes.

So on that evening in 1994 it was “Just Another Day” – but it was a really good one!

Jeff can be reached at djwhal@icloud.com