John Shook once wrote about “Five Things Missing from your Standardized Work.” If you have not yet read this three-part eLetter, I highly recommend it. Shook shares that the need to “practice, practice, practice” is too often overlooked when companies decide to implement Standardized Work. As a way to facilitate effective practice while training, he suggests consideration of Training Within Industry’s Job Instruction method.

The history of Training Within Industry (TWI) is truly fascinating! Check it out. After nearly disappearing from use in the United States, where it was originally developed just prior to World War II, Job Instruction’s popularity has experienced a resurgence over the last decade. Today, it is used across the world by companies as diverse as Toyota, IBM, and Starbucks.

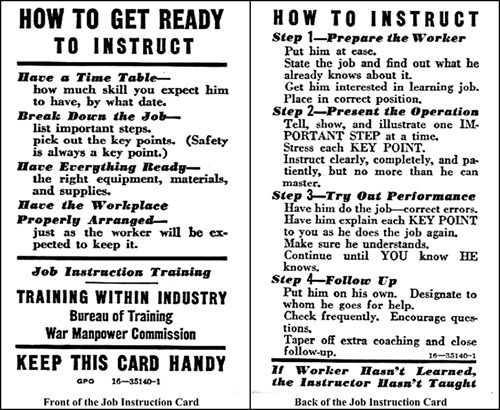

Job Instruction is a four-step method that teaches an individual how to do a job correctly, safely, and consistently while meeting all requirements. As you can see on the card at right from the original TWI program, the four steps are:

Job Instruction is a four-step method that teaches an individual how to do a job correctly, safely, and consistently while meeting all requirements. As you can see on the card at right from the original TWI program, the four steps are:

- Prepare the worker

- Present the job

- Try out the job

- Follow-up

The training experience includes seeing the job, hearing the job described, trying the job (hands-on) immediately, describing the job, and being supported until fully competent. The worker benefits by gaining competence quickly. Companies see an increase in quality and productivity.

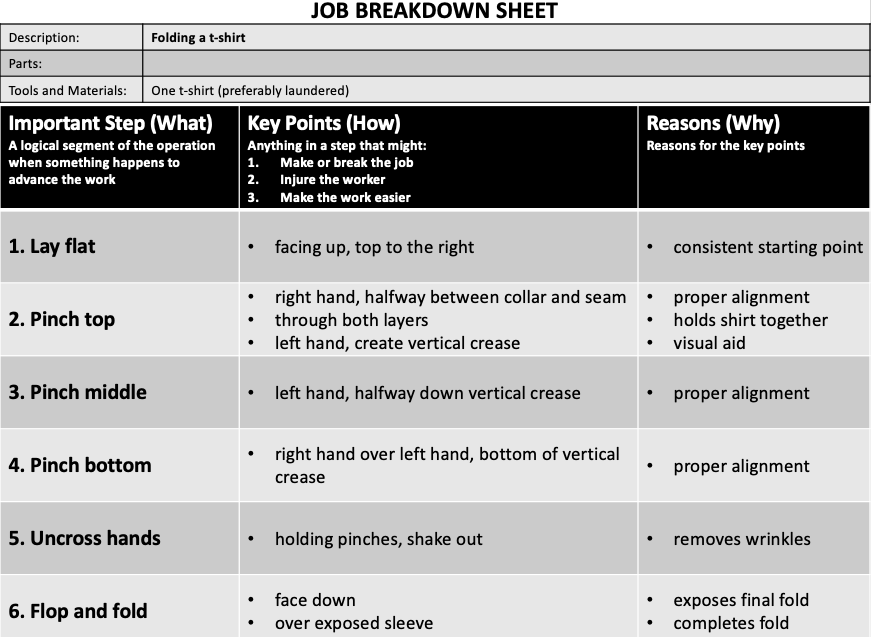

The trainer relies on a set of notes, if you will, called a “Job Breakdown Sheet.” This template breaks the job down into “Important Steps,” “Key Points,” and “Reasons Why.” This information is shared with the worker a little bit at a time, at an appropriate pace for the individual. I’ve heard this described as “layering” or “just-in-time” training.

I hope you enjoy and find value in the video demonstration below, in which I train my colleague on how to fold a t-shirt the LEI way!

Here is a copy of our T-shirt folding Job Breakdown sheet or create your own with this blank template.

Update: An earlier version of the Job Instruction demonstration video did not include a key technique. The technique, as noted by the commentor Pat Boutier, is to say the terms “Important Step” and “Key Point” as audible cues for the learner to help them organize the information they are receiving.

Investing in Work(ers) Using Job Methods and Job Instruction

Learn how to develop team members for sustained success.

I recall that sometime in 1993, we were a group of engineers trained on a new detection technology. The trainers came from Atlanta and we learned this methodology to coach and train other engineers locally. At that time, I took my handwritten notes, but we were not told about the interesting background behind this TWI methodology. It is genuine and effective leadership. Recently, 2 years ago I recognized this method from a Dr. Womack’s conference and the crucial history behind during WWII.

Very clear and easy for trainees to grasp and understand. The trainer gave a step by step demonstration. Each step performed was coupled with the highlighting of the key points and reasons such the key points. Thus the trainees would be able to grasp and follow easily. Easy to understand and follow

Well done and congratulations.

From :A retired OJTTrainer (Singapore)