I was recently talking with the CEO of a large insurance company who said, “Our people seem to know lean concepts and tools, but they are not being lean as they go about their daily work!” If this sounds familiar then read on.

After years of training, workshops, and books on lean and continuous process improvement, most organizations applying lean have not realized the performance breakthrough and cultural shift they wanted. I have visited numerous organizations that have invested years undertaking lean activities (value-stream mapping, A3 problem solving, visual management, leader standard work, kaizen, etc.) but have little to show for their efforts in terms of sustained value-stream performance, quality, productivity, effectiveness, safety, and efficiency gains.

This is an issue we as a community need to take an honest look at. Perhaps there are some missing elements that we need to be considering. Is it possible that we’ve gone on “autopilot” and are just going through the motions without engaging our minds? Have we become robotic in our lean thinking and doing? Have we become so comfortable with the knowing of lean that we have lost touch with the being of lean?

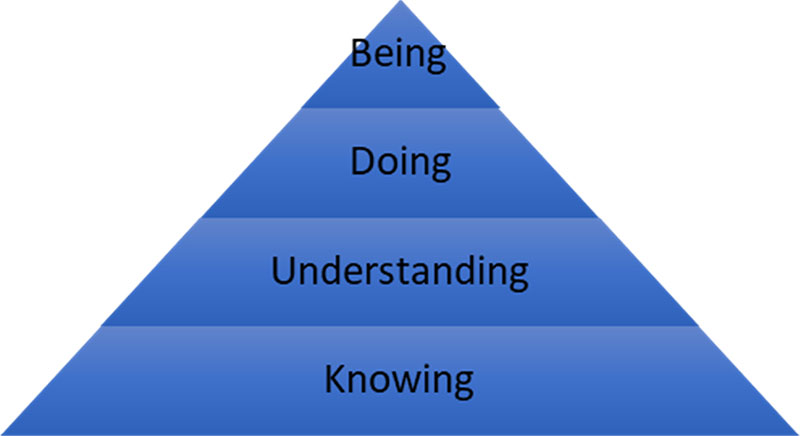

Four Levels of Awareness

A state of being known as mindfulness presents a path forward. Mindfulness is defined as “a mental state achieved by focusing one’s awareness on the present moment, while calmly acknowledging and accepting one’s feelings, thoughts, and bodily sensations.” Mindfulness has gained lots of attention in the business press over the past decade. The Centers for Disease Control and Prevention (CDC) journal Preventing Chronic Disease reported that “approximately 1 in 7 workers report engagement in some form of mindfulness-based activity, and these individuals can bring awareness of the benefit of such practices into the workplace.”

You are probably familiar with the classic four stages of awareness:

- Unconscious Incompetence – blissful ignorance (not knowing that you don’t know something)

- Conscious Incompetence – painful awareness (realizing that you don’t know something)

- Conscious Competence – intentional awareness (knowing what you know and don’t know)

- Unconscious Competence – unaware but knowledge and experience has taken over

Initially described as “Four Stages for Learning Any New Skill”, the theory was developed by Noel Burch in the 1970s.

Isn’t it interesting that unconsciousness competence emphasized the autopilot nature of our thinking? Perhaps this works for a few people, but the rest of us would be better served relying on mindfulness and conscious competence to develop deeper levels of focus, analysis, experimentation, reflection, and learning. To that end, please consider the following model:

Four levels of awareness: Knowing, Understanding, Doing, and Being

A Good Place to Start

Knowing is where we typically begin by training people in lean basics: principles, systems, and tools that make up the lean body of knowledge. While knowing key concepts and models is certainly needed, by itself knowing does not necessarily lead to major changes in behavior. I may know eating pizza is not good for my health but that knowing does not stop me from ordering a large pizza most Friday nights!

Understanding occurs when we mentally process the new information we have learned, compare it to what we know and don’t know, and create context and perspective. We reconcile the new knowledge to give it meaning in relationship to everything else we believe we understand.

But even solid understanding does not drive sustained changes in behavior. John Shook addressed this issue in his landmark “Lessons from NUMMI” article in 2010. In that piece, he wrote, “It’s easier to act your way into a new way of thinking than to think your way into a new way of acting.” This key insight is attributed to Millard Fuller, Founder of Habitat for Humanity.

Activity with Mixed Results

Doing is where many organizations find themselves – they are diligently putting up team boards, updating metrics, holding team stand up meetings, updating A3s, developing countermeasures, going to the gemba, and so on. There is a concerted effort to accomplish the tasks of continuous improvement. Kaizen events, team huddles, and the lean management system have been determined a success, but at the end of the day, not much has changed!

Let’s pause here; how accurate is it to suggest that “not much has changed” If we define change in terms of sustained gains in value-stream performance, quality, productivity, effectiveness, safety, and efficiency gains? Go take a walk around your company and honestly assess the level of sustained gains when viewed through this lens of awareness.

Just as understanding is needed for clarity around the “why” and “what” of lean, doing is the action needed to close the gap between where we are and where we want to be. Someone once said, “A tool is only as useful as the user.” If a team using lean is operating at knowing, understanding, or doing levels, problems are not deeply understood, changes are not permanent, and solutions are not sustained. We can often find ourselves so absorbed with the challenges of achieving our daily work goals that we lose focus and reliance on process improvement – we are doing lean, but we are not being lean.

To move to action, we need to move from understanding to doing. However, to sustain the change, people must progress to the next level of awareness – being.

Being Is a Whole New Ballgame

Being is the calm, focused state of mind where we are fully present and aware of what is here, right now. When we are in this state, the mind is nonjudgmental and accepting of the current situation. Acceptance does not mean approval; it means that we grasp the situation for what it truly is, in order to take steps to improve the situation and close the gap. With acceptance, we do so with a clarity of mind and calmness of thought that leads to a state of allowing things to be as they are while moving towards an improved target state.

Acceptance, acknowledgment, and allowing things to be as they are, versus resisting, judging, or making excuses for them, gives us a powerful edge for direct observation, which often reveals underlying contributing factors to the current conditions.

Being delivers a key element that is missing from doing: space for the mind to be more relaxed, more creative, and less stressed. As we become more present and focused on the moment directly here and now, the mind becomes calm, curious, and accepting. Mindfulness positions us to approach problems dispassionately, which directly supports lean thinking (structured experimentation, reflection-based learning, connecting with people on an authentic level).

In the next post, we’ll explore some specific mindfulness practices you can apply to boost your effectiveness at being lean.