A follow-up Q&A to the “Lean Digital Transformation” webinar with Presenter Bruno Guicardi, president, CI&T

The Lean Digital Transformation webinar with Bruno Guicardi, co-founder and president of technology services company CI&T, drew a global audience that submitted hundreds of questions, many more than he could answer during the hour-long presentation.

Many questions were about the cultural transformation at CI&T, summed up by, “Could you please share with us the three most important things to work on to start changing a culture from lean traditional to lean digital?”

Read Bruno’s culture change answer below then watch the webinar to learn:

- Why enterprises take more than 2 years on average to go from an idea to digital experience in the hands of customers even when they already using agile;

- How the use of value streams accelerates digital delivery and what are the organizational changes necessary (report structures, incentives, metrics) to get the most of this new model;

- How lean principles create the foundation for the cultural transformation necessary for collaboration and innovation in big companies.

- How a lean digital transformation combines the principles of lean management, agile development, design thinking, and cutting-edge digital technologies to dramatically improve speed to market, customer experiences, and corporate culture.

- How lean digital principles worked in a real-world transformation with a Fortune 500 client.

We selected other questions that represented the main issues you wanted to know more about for this follow-up Q&A with Bruno. You can access the presentation and webinar at LEI’s Webinar Library.

Q: While my intent is to do a PhD on this issue, I do find that operations management programs within schools resist including the “people” component, whereas organizational behavior departments only talk about the “human.” My question is, does lean management bring these two fields together?

Bruno Guicardi: Absolutely! Lean focuses on changing the work in a way that’s respectful of people’s abilities to incorporate new skills. It ensures that on one hand people are continually being challenged. On the other hand, support in the forms of training and coaching, and time to practice in an operating environment are essential for people to develop these new skills.

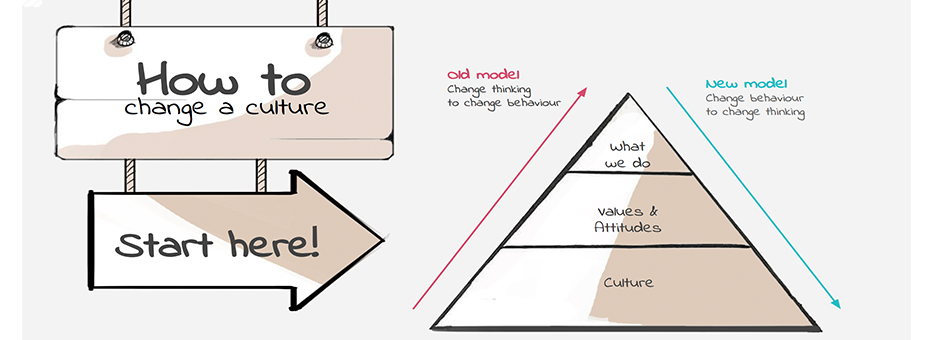

Q: You said, “change the behaviors to change the thinking.” How do you change behaviors at first? Do you apply command and control initially?

Bruno: Start with need. Find people who are open to a new way of doing things. My tip would be to look for business leaders within the organization who have a big challenge at hand—either a crisis or a great business opportunity that these leaders are willing to tackle differently. It’s very tough to install a radical change if everything is going really well. Anyone would (rightly) claim, “Why change if we’re doing so well?” With the willingness to change out of the way, then it is time to systematically introduce change. We use many concepts in this phase, most importantly the Shu-Ha-Ri method, which matches well Prof. Edgar Schein’s theory of providing a role model to be followed before asking people to do it by themselves.

Q: Where does value-stream mapping fit into what was done at the bank you cited?

Bruno: VSM was central to raising awareness of the total lead time. Each area was familiar with their own part of the process, and no one really had a complete view of the end-to-end process or how long it took. We were shocked when we found out that the product development lead time took 24 months. After realizing this, it was very important to provide insight into the reason for it. It was vital to understand the main root causes for the long cycle and for the low-flow efficiency which were: (1) a great number of handoffs from one area to the next and lot of back-and-forth among them; (2) constant re-prioritization of work within each area creating a lot of WIP.

Q: How long did the transformation kick-off meeting last at the bank to bring all the stakeholders onto the same page?

Bruno: The whole assessment phase using A3 plus design thinking took two to three weeks. It was a mix of an all hands-on workshop and individual interviews.

Q: Thank you for your insights. The approach you described is similar to a method called lean startup developed by Eric Ries in 2011. Are there any differences between the two methodologies?

Bruno: There are similarities as we incorporated some of Ries’ concepts into our system. The main differences are:

- The way we are integrating A3 plus design thinking as one consolidated method to create cross-functional alignment and unlock real collaboration;

- The way we are planning, designing, and introducing change within a PDCA cycle that is apart from the value stream’s PDCA;

- Also, we use principles like “skin in the game” (hands-on coaches), bold goal (summit of the mountain), and short cycles (camps) with measurable business impact at the end of each cycle (usually agreed upon with objective and key results or OKRs.)

In summary, Ries’ ideas are about how to introduce a system for constant value discovery. Our contribution builds on that but is a system to incorporate change continually.

Q: Changing a culture is very difficult. Could you please share with us the three most important things to work on to start changing a culture from lean traditional to lean digital.

Bruno: First, I would recommend finding a business leader who’s willing to try new things and who has the CEO’s support. In our experience, we find that often the authority to provide the waiver needed to assemble real cross-functional teams resides solely with the CEO. My second tip would be to run away from the “big bang” approach—to change everything everywhere. Focus on depth instead of breadth. This will give you business results much faster, even if it is localized and small-scale, and most importantly a new group of lean thinkers who will become your advocates and will help you promote the “new way”. Finally, don’t try to change the culture! Instead, organize yourself to solve impactful business problems in a new way of working. As a by-product, if you’re successful, the culture will change naturally.

Q: How would you implement these principles with virtual teams?

Bruno: All of our engagements involve remote teams. In our experience, the main challenge with distributed teams is how to create trust among them, and to debunk the common idea that comes from the corporate world, which is: “whoever is not in our team, sucks.” Remember that it’s critical to have a high level of collaboration across teams in order to be able to self-adjust in environments of high uncertainty. If you don’t have trust, forget about collaboration!

So I would advise you to assess the level of trust you have across teams and invest accordingly to build empathy, trust, and collaboration, in this order. Investments like flying key people (not necessarily everybody) from all teams involved to one place to have rich interactions in critical moments are important. Another key thing is to provide the support for change (the Shu-Ha-Ri) locally to every team.

Q: Do you need to do some training with leadership ahead of time to change their mental models of how to interact with staff and vice versa?

Bruno: Leaders get training in basic concepts like agile, lean, and design thinking. However, that’s only 1% of the program; the 99% comes with the change in the real work being done by the leaders. For example, we replace project status report meetings with gemba walks. This way, all levels of leadership can see the team’s visual center or “situation wall” and understand the team progress and struggles. The situation wall provides essential transparency—a “no-filter” approach to team performance. Leaders’ behaviors change a great deal when, instead of reviewing all-green project scorecards in their rooms, they spend quality time with the teams discussing their real issues and learnings.

Q: Do you have a maturity model that you reference with client leadership to give them a view of how the transformation could progress over time?

Bruno: We are a bit skeptical when it comes to maturity models and playbooks to solve this type of challenge. These are good solutions for solving problem domains of “known knowns” and “known unknowns” but not for the “unknown unknowns,” which is the environment we’re dealing with most times.

If you try to be prescriptive in this environment you lose your most indispensable weapon which is the ability of your empowered teams, who are closer to the action, to probe, sense, and respond in the best way possible. We measure the progress of the transformation by the impact we are able to create in the business, the culture, and leadership change are by-products of a new way of doing things that are more successful than the previous way.

What to do next:

Read the Lean Post article “It Starts Within: the Lean Journey of CI&T.”