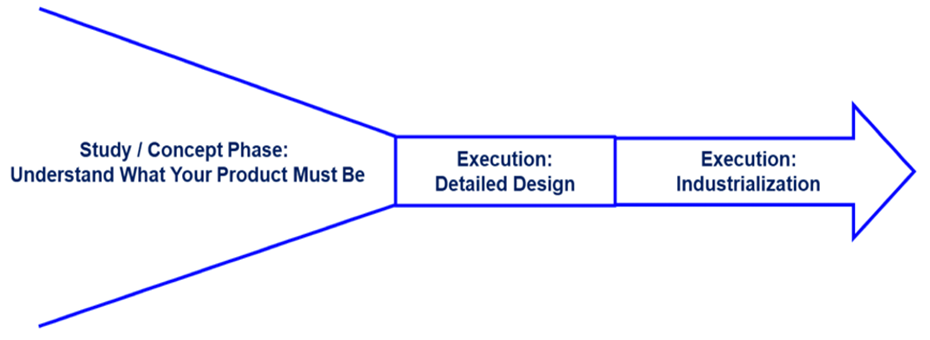

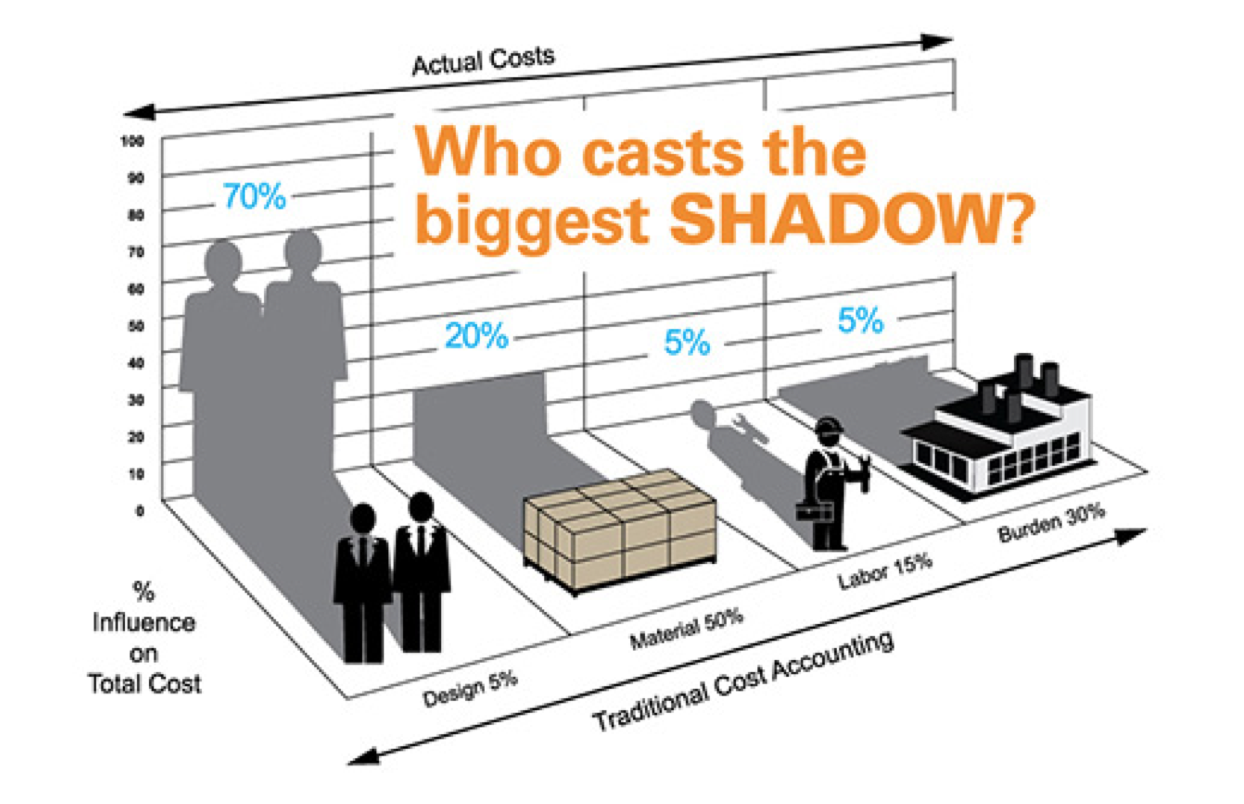

When managing or improving a business we often focus on the areas that have the biggest contribution to the bottom line. The biggest opportunity to impact these costs comes during the design phase (Figure 1) since decisions made during design lock in the on-going costs. These costs aren’t just financial, but environmental as well. Many of these costs are not consciously decided, but rather are decided for us when making design decisions without understanding the environmental impact. While kaizen events or lean management projects will reduce production costs after launch, cutting environmental costs post-launch is harder. And many post-launch improvement efforts are rightly viewed as re-work that we can eliminate by designing efficiencies into the original design.

Figure 1: Influence of Decisions on Cost (Copyright Munro & Associates, Inc.)

Consumers are also demanding and updating products more frequently, which is great for businesses and consumers. These new products are usually more efficient with lower carbon emissions when they are being used than the products they are replacing. However, we often forget to consider the environmental impact of making more products as we upgrade more often. A third of man-made carbon emissions come from making products.

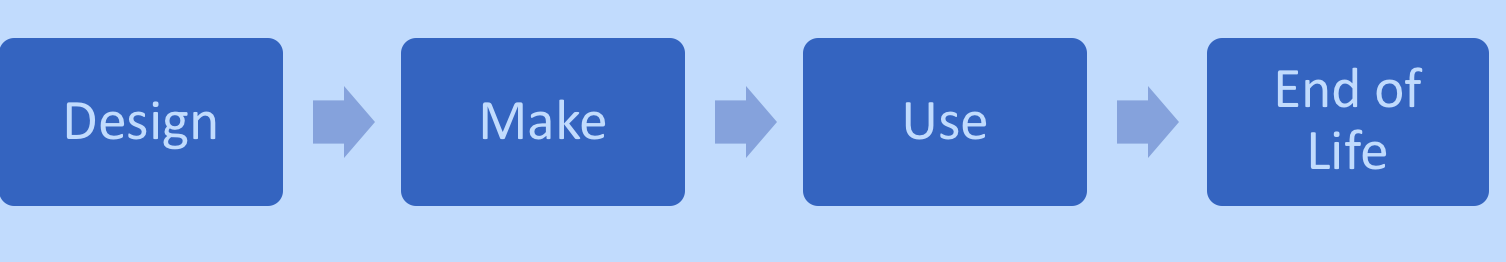

As the need to reduce carbon emissions becomes clearer, as laid out by The Intergovernmental Panel on Climate Change, the need to understand the impact and consciously consider it during the design phase is ever more important. Lean Product and Process Development (LPPD) principles, methodologies, and management behaviors are a system that enables the environmental impact of the entire product life-cycle (make, use, end of life) to be consciously considered in the design phase.

Figure 2: Product Life Cycle Phases

Understanding what is driving carbon emissions in production is the first step to lowering them. Approximately one-third of the carbon emissions from making things comes from metal. Metal has a high scrap rate throughout the global supply chain with 25% of steel and 40% of aluminum being scrapped. This provides a large opportunity to reduce carbon emissions by reducing the amount of material that is scrapped through better utilization.

Another major driver of carbon emissions in production is the energy used to make products. The impact of this is amplified by increasing use of energy-intensive materials and new manufacturing technologies such as additive manufacturing, whose green credentials are still unclear. Another key benefit to reducing the amount of material scrapped and energy used in production is that both drive significant cost reductions, which have a direct impact on the bottom line.

Despite this, material and energy utilization are rarely considered in the development process, or are not considered until late in the process when the design and impact on the environment are already locked in. Asking designers and developers to consider the environment, is easy to say but hard to do. So, we need a way to build this thinking into the development system, which is why I have been collaborating with Dan Cooper in the Resourceful Manufacturing and Design group at the University of Michigan on how lean product-process development can provide the structure that enables low-carbon manufacturing principles to be built into the development system.

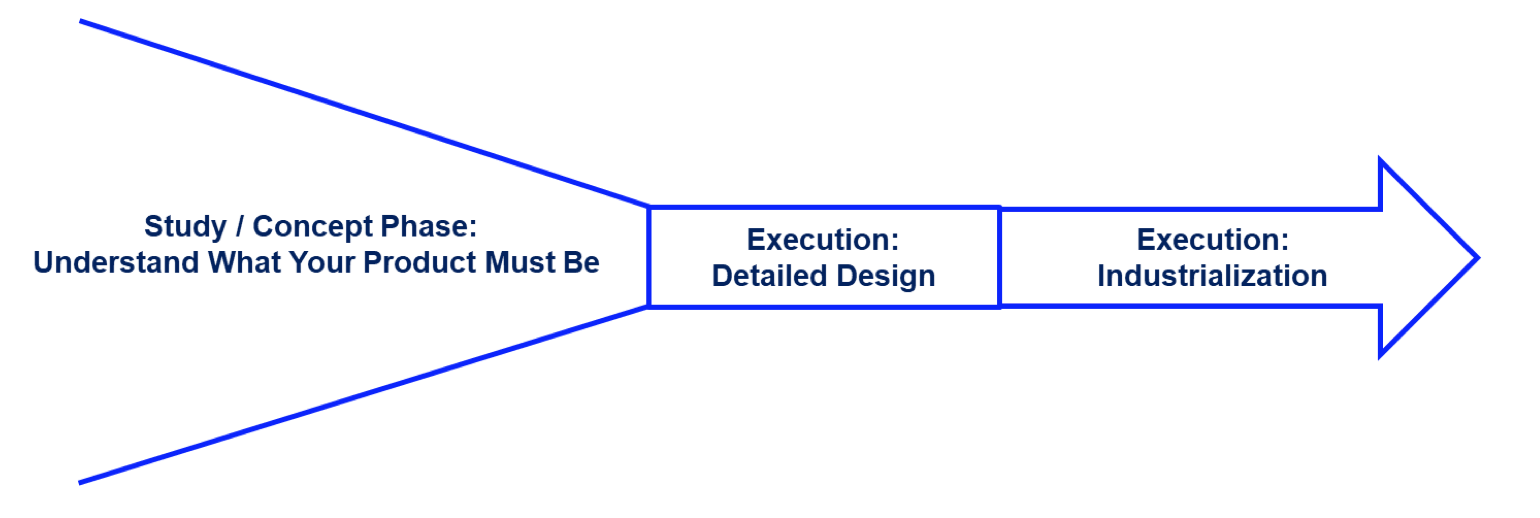

One of the principles of lean product and process development is to deeply understand what your product needs to be in the study or concept phase (Figure 3). This includes both from the customer / user perspective and the various business perspectives that exist within organizations. Sustainability/low-carbon emissions can be both a customer/user and a business perspective. Amongst others another commonly considered business perspective is the cost of making the product.

Figure 3: Typical Phases of New Product – Process Development

Within the study/concept phase a combination of lean tools and modified sustainability tools are utilized to consider the environmental impact of products throughout their life-cycles. Chief engineer immersion is another method that focuses on observing how products are used can be valuable to understand what is important to users in the use phase, including sustainability aspects. Another valuable piece of input in the study phase comes from using life-cycle analysis predictively. Life-cycle analysis is typically done after a product has been designed to understand the environmental impact across all stages of the life-cycle. Life-cycle analysis for similar recent projects could be used to understand the environmental impact and drivers, so that when decisions are being made that knowledge is considered. These perspectives can then be captured in the concept paper, which is used to get cross-functional alignment on what the product needs to be. Sustainability and low carbon emissions across the entire product life-cycle can be part of the conversations and trade-off discussions with stakeholders in the process of socializing and writing the concept paper with targets being set to achieve the product vision.

Another one of the LPPD principles is to create flow and eliminate waste for speed to market, which comes into play when you transition into the execution phase of development. This includes creating actionable plans to meet the targets set in the concept paper, including milestones and glide paths to meet the targets. Since product development is a team sport it takes effective collaboration to meet the targets, which are supported through having compatibility before completion and using obeya rooms effectively. At Ford, body engineering and stamping engineering were able to improve material utilization by nearly 10% per program utilizing the idea of compatibility before completion through feasibility checkpoints. This is an example of how LPPD enables dramatic cost savings and lower carbon emissions.

Creating new value through learning is also a core lean product-process development principle. As the organization gains more knowledge on designing efficiently for material and energy utilization, this knowledge should be captured in design guides and standards. This enables the knowledge to be accessible and used when designing future products. It also creates a mechanism for developing engineers, which aligns with the lean product-process development principle that it is all about people. Lean product-process development provides the system and structure to enable people to bring their best selves and contribute to making great products that are design efficient from both a financial and environmental perspective.

What To Do Next:

- Participate in research: In collaboration with the Resourceful Manufacturing and Design group at the University of Michigan, there is on-going research on this topic. If you have utilized any of these methods resulting in lower carbon emissions and are willing to participate in the research please contact us at appell@umich.edu.

- Learn Lean Product and Process Development, increase your professional skills, and enhance your value by registering for the in-depth workshop with LPPD instructors John Drogosz and Katrina Appell, Designing the Future: A Lean Product Development Immersive Learning Experience. Since LPPD is an enterprise activity, managers, leaders, designers, product developers, engineers, and continuous improvement agents are encouraged to attend.

- When you practice Value-Stream Mapping for Manufacturing at this comprehensive workshop, you’ll understand how to apply lean management techniques for maximum impact and improved flow of value to customers. Mapping helps you avoid the common mistake of cherry-picking individual lean techniques, which creates isolated islands of improvement and limited benefits.

Designing the Future

An Introduction to Lean Product and Process Development.