Dear Gemba Coach,

We’ve had spectacular lean results with our old boss, but our new boss doesn’t get it. He’s already cut his gemba walks from weekly to monthly and doesn’t see the point of kanban. What can I do to convince him?

I honestly don’t know. This has to be one of the most frequent questions in lean and I have to confess I have not found an answer so far. The real problem is that bosses already know everything (that’s how they get to be bosses) so convincing them is not an option. The real problem is showing them something where they can convince themselves.

And, there we get stuck. If we show them the full TPS, they just balk. Understandably as it’s both alien and complex:

If we introduce them to lean piecemeal, by going the “simplified” way, they tend to latch on to one part of the system, figure it out (they’re rarely thick), delegate it to someone to fix operations, move on, and so never get it either.

Let’s try yet another way to skin this particularly resistant cat. What is TPS supposed to teach us?

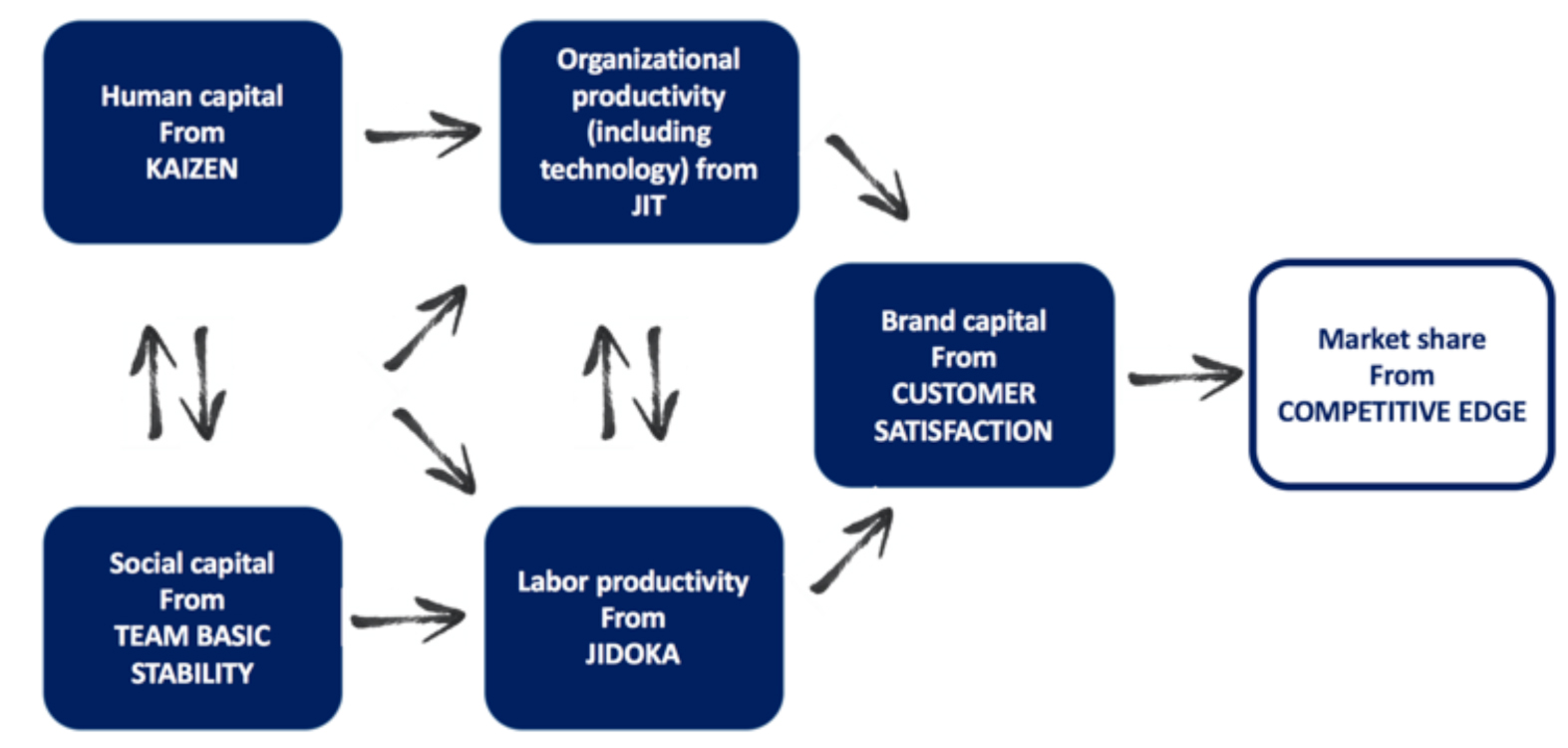

First, how to satisfy the customer better: this is developing brand capital. The assumption is that in a saturated market we gain market share faster by reducing churn (keeping existing customers happy) than by seeking to “acquire” new customers. The approach here is to try to understand fit-to-customer better, and the learning method is VA/VE: value analysis to fix customer issues in the current contract (and learn about how they use our products or services) and value engineering to improve future contracts (and test customer preferences by proposing new features).

Then there is jidoka (if you read the Asian pictograph right to left), which is learning how to make our products better: this is developing labor productivity. By focusing on self-detection and not accepting defective work, not creating defecting work, not passing on defective work, but, on the contrary, focusing on every problem as it appears in context, we develop a deeper understanding of both our own work and the equipment used. We also better understand the “process point,” where the tool hits the part.

Just-in-time is all about learning to coordinate departments and functions better to deliver to customers quickly, with the existing capacity while introducing variety: this is developing organizational productivity. By pulling work as needed as opposed to doing the job and pushing the batch to the next step when it’s done, all departments in the full supply chain learn to coordinate better and to level the load and make their equipment more flexible, which radically improves capital utilization (and leads to machine redesign for flexibility). The learning tools here are good ol’ fashioned kanban and SMED – no surprises.

Employee satisfaction is achieved by developing team-level kaizen and standardized work and easing the flow of work both at individual and process level: this is developing human capital. As teams learn to improve their own work environment and to handle their various jobs better, and as they are engaged in establishing their own ways of working in order to achieve their mission, they develop unique knowledge as well as greater engagement. This knowledge, when cumulated over time and place through the intensity of kaizen, is the key to competitive difference as it both makes the operational process more efficient and can be fed into engineering work to design the next generation of products and services at greatly reduced cost (The aim is to reduce existing costs by 30 percent.)

Mutual trust between employees and management is the key to basic stability. It’s achieved through supporting the right team structure and the right atmosphere within teams (Google reached the same conclusions) where people feel confident in their own skills and at ease with each other, their colleagues, and their management: developing social capital. This is achieved by developing shop-floor leadership through constant on-the-job training and teaching team leaders and frontline managers the basics of “labor relations”: how to help employees with individual problems and reinforce team spirit.

The full model would look something like:

I have no idea whether this would be any more convincing, but I fully believe your question is the right one, and we must keep trying until we find the right way to present lean that is attractive to senior managers without being over-simplistic. Try, see, try, see … and hope for the best!