As lean thinkers, I know we learn best by example. In my work preparing tomorrow’s leaders with Council of Supply Chain Management Professionals (CSCMP) Southern California Roundtable Board of Directors, I find that having vivid illustrations of ways that lean has dramatically improved real-life gembas has the most impact in teaching the next generation.

At CSCMP’s Lean Leadership Summit in May, we’ll be hearing two unique applications of lean systems thinking.

Shirley Weber (Director Laboratory Services) and Katie Abbott (Sr. Program Manager, Business Operations) will tell the story of the construction project of Stanford Hospital’s new buildings and its associated operating costs. There’s an amazing transformation happening in the labs, the benefits of which are already delivering to existing operation, and by reducing requirements for the new buildings, will deliver greater benefits for decades to come.

All supply chains suffer from spike demand. But, as you will hear from Jeff Koga (former Marine and Associate VP, Oshkosh Corp.), when IEDs in Iraq and Afghanistan began killing and maiming thousands of our troops, the ramp up to manufacture, assemble, and transport the components—and organize the in-country workforce to double the threat protection of thousands of Humvees and other vehicles in more than 50 bases across a multi-country theater of war—this was unlike anything most of us have ever seen. It makes most of our supply chain problems look like child’s play. And now that the U.S. is cashing in on the “peace dividend” we’ll hear how lean thinking enabled Jeff to sustain profitability during ramp down.

I’m especially looking forward to you hearing Gary Convis, former Executive VP of Manufacturing USA and first non-Japanese Managing Officer of Toyota Motor Corporation (who led Toyota’s North American manufacturing development from the beginning at NUMMI). Convis will also speak about how as CEO of Dana Holdings Corp. he led an incredible turnaround from near bankruptcy during the recession.

And Toyota’s VP of Production Control, Doug Formby, will explain how Toyota manufacturing used the crises of the Great Recession, recall crisis, and Great Japan earthquake to make unheard of advances in market responsiveness and flexibility, productivity, quality, and capability development.

The Summit will be a chance for supply chain professionals to come together and discuss two trends in the supply chain field that we can no longer ignore:

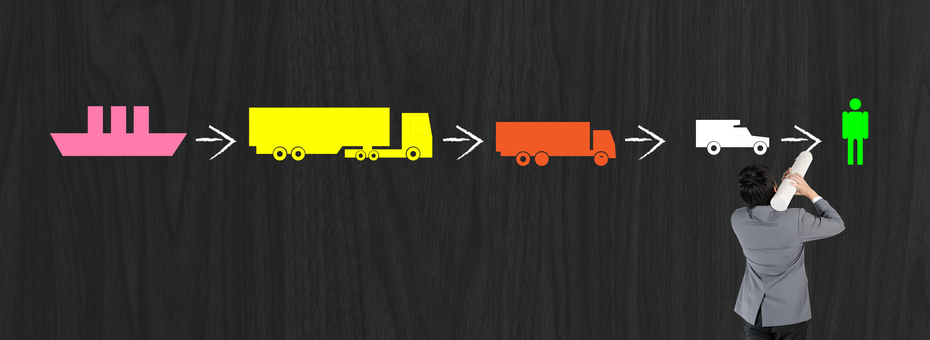

- #1: The need for collaboration across value stream functions and across the extended enterprise to develop an aligned and synergistic system

- #2: Siloed operations. We must break down silos that create conflicting goals and priorities and prevent effective connections between the various links of a supply chain

What’s next for our CSCMP chapter? In the last five years, I’ve seen our chapter more than double in size. To prepare tomorrow’s supply chain leaders for the growing complexities of global supply chain management, we’re focusing our energies on educating and connecting these young leaders.

We do this by:

- Hosting presentations by leading supply chain experts

- Leading tours from world-class supply chain operations such as Toyota’s North American Parts Center or Kroger’s highly-automated distribution center, to more entertaining venues such Dodger Stadium (to understand the logistics of transporting the team to away games and supplying the crowds at games) and Disneyland (to understand what it takes to deliver Disney magic)

- Engaging young professionals on our board of directors to accelerate their learning and develop the next generation of leaders

And in the realm of service, we’re doing the following:

- Giving scholarships to talented students pursuing a degree in a supply chain field. 100% of our chapter’s growing net proceeds from events goes to our scholarship funds

- Supporting and mentoring supply chain/operations management groups on college campuses

- Partnering with ITEP (International Trade Education Program), a highly relevant collaboration as the twin ports of Los Angeles and Long Beach (the largest port complex in America) are in our back yard. ITEP is primarily focused on exposing high school students in lower income communities surrounding the ports to career opportunities, providing mentoring and internships help students visualize career goals, gain knowledge and experience, and with scholarship support, be the first in their families to go to college. This year’s scholarship dinner raised over $250,000.

Breaking down silos and collaborating cross-organizationally is increasingly important. I want to learn from you what challenges you have in creating allies for process improvements in other functions of your value stream, how you are overcoming them, and how we can better structure our May 21-22 summit to share ideas with both speakers and like-minded attendees to accelerate your creation of competitive advantage through lean system thinking. Please share your posts with us.