Some business problems require a quick reaction to “stop the bleeding” while others require creativity or more analytical approaches to reach better target states or attain breakthrough results.

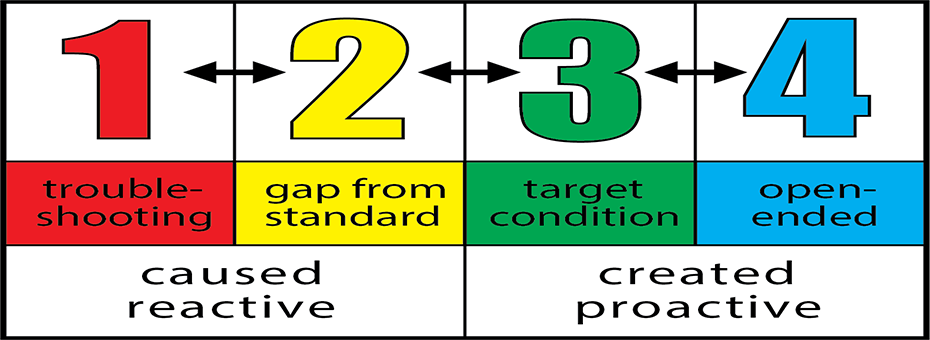

No matter the problem, it probably will fall into one of the types in the helpful framework that author and veteran lean management practitioner Art Smalley introduced in his recent book, Four Types of Problems. The flexible framework helps leaders and teams apply the right problem-solving approach by recognizing the four problem types:

- Troubleshooting: A reactive process of rapidly fixing abnormal conditions. (When a house is burning, extinguish the fire.)

- Gap-from-standard: A structured problem-solving process that aims at the root cause. (Determine what caused the fire and how to prevent another.)

- Target-state: Continuous improvement (kaizen) that goes beyond existing levels of performance. (Use superior building materials that are much less likely to lead to fires in the first place.)

- Open-ended and Innovation: Unrestricted pursuit through creativity of a vision or ideal condition that entails radical improvements. (Ask why not have systems that detect, prevent, or immediately stop fires from occurring right away?)

In this interview, Art reflects on why we make the mistake of reaching for the same problem-solving technique over and over, how the framework helps us talk about problem solving, and why troubleshooting is so important. Finally, he offers examples of different types of problems when he gets locked out of his hotel room by a faulty lock.

Q: Why is it, and this is an insight in the book, when faced with a problem many business leaders or team members reach mechanically for an A3 or kata or six sigma or the eight types?

Art: What behavioral psychologists tell me is that two things influence how you tend to learn, teach, and problem-solve. Number one is whatever framework you learned first, that is going to put a pretty dominant brand on your brain and how you choose to look at things.

The other way of looking at it, though, is how you like to learn, teach, coach, problem-solve. Do you go more towards concrete things? Do you go more towards abstract things? Do you go more towards people? Do you more go towards numbers? Do you go more towards reflection? Do you go more towards actively learning by doing?

All those are good things, which are part of problem solving, but you will have a bias. We can put you on a radar plot in a quadrant. I can predict with about a dozen questions and people’s responses what quadrant they’ll end in.

People that love to reflect and think hard about ideas and using a numbers approach tend to prefer six sigma. If they learn six sigma first and their preference is for six sigma, they’re going to dogmatically adhere to that in many cases. By the way, it’s a great approach for a lot of specific types of problems. I minored in math and had a specialty in statistics, so I got a bias in that direction. I did process control and capability studies on crankshafts, so I’m comfortable in that field.

I also know that it’s not the best way to talk to people because there’s also a quadrant of people who are more interested in people and objects and doing things, not numbers. Statistics turns them off. They’re feeling-based. They’re emotion-based. They’re 3G — go and see, get the facts, grasp the situation. They must grasp it with their hands, not the data.

Those people like to learn by doing and have an implementation-based approach to problem solving. Again, there’s nothing wrong with that. That’s a big part of problem solving at Toyota. We talk about learning by doing, but again, if that’s your only way of approaching problems, you’ll suffer; you won’t be able to reach some of the audience.

There are other quadrants such as the converger quadrant if you like plan-do-check-act (PDCA) or kata. You’ve got to make a cycle and spin it and you solve that. You think that solves every problem, and for you it does.

The opposite quadrant for that is the big thinking, open-end strategy group which says, “Well, you’re just rearranging the deckchairs on the Titanic while your business model fails. You’re Nero fiddling while Rome burns, so to speak. You’re not even working on the right problem in that quadrant. Think about the big picture in the strategy.”

The point of the framework is not that any one of those is right or wrong. It’s like situational leadership. Depending upon the task, the person, the problem you’re working with, you might have to alter your pet framework to have the most effective dialogue.

Any approach can work, but it takes more effort sometimes. [LEI Senior Advisor] John Shook and I wanted to come up with a framework where you can flexibly shift gears, look at problems from different points of view, and come up with the most effective way to interact with people and approach the process.

Q: You make that point. This is really a framework, a way to talk with people and solve problems.

Art: Yes, and to frame things. If you don’t have a framework that is flexible enough to handle a multitude of situations, then it does feel like you get stuck; one approach for all problems, which may or may not be right for that problem. And it may or not be effective with the learning style of the person you’re interacting with.

Q: Now, one of the problem types is type one, which is troubleshooting. You don’t hear a lot about it, but you emphasize its importance, and this is not just firefighting.

Art: There are bad firefighting and bad troubleshooting, and there’s good troubleshooting. In Toyota, I think it’s underrepresented how good we are at daily troubleshooting. The math is really simple. There are 10,000 andon cord pulls in a 24-hour period during a launch. You cannot do 10,000 A3 reports.

You cannot have 10,000 sessions where we sit down and do a coaching kata routine in a day. You cannot do six sigma-style process control studies in a 24-hour window. It’s not possible. Toyota doesn’t do that. What we do is triage. There are those little things we want to handle at the frontline through team member, team leader, or group leader interaction.

Not all of those go to type two status. Not all of them have a really hard root cause, but it’s coaching the training. It’s coaching the standardized work. It’s debugging something that’s slightly wrong.

We all do it. You can be the purist and say, “I never do that. I only coach type two.” But guess what? When your internet router at home is not working, what do you do? You turn that sucker on and off, don’t you? You get your internet connectivity working again okay because it fixes it in a minute and you don’t know what the root cause of the problem is.

Q: You travel a lot. I’m sure a lot of people watching travel a lot. Now you just had an example of problem-solving types here at the hotel.

Art: Again, you can say which of the four approaches is best for the situation, the task, and the person I’m facing, but you can also take the view that any problem can be viewed through four different lenses, for example. Most people who have traveled or checked into a hotel can relate to this.

I was given my card the first night I checked in and went up to try and get in my room. I was on the 11th floor. Guess what? The card key didn’t work. I’m tired, it’s the end of a long travel day, got my suitcase and my backpack. I’ve got to go back to the elevator, go back downstairs, where a lot of people are checking in. I stand in line. I wait. I finally get to the desk and, of course, the initial response is, “Oh, you demagnetized your card.”

Q: Of course. Your fault

Art: The five “who” maybe. It happens. That’s why they give you that quick response. I go up upstairs again. Card doesn’t work the second time either. I come back downstairs, “Look, gang, it isn’t working.” They say, “Oh, I’m so sorry; apologize for that. We’ll send maintenance.”

Well, I go upstairs, wait for maintenance. They come with a special device. They check the lock on the door, and it’s not working. “Oh sir, this is broken. I’m sorry. We need to get a new battery for you.” He gets the battery, comes back in. I’m standing waiting. He puts the battery in. Lo and behold, it works. It was a bad sequence of troubleshooting.

The next night it happens again. So there’s something wrong with the door. This time they did good troubleshooting. They sent the maintenance person immediately back up with me. In five minutes, I was in the room, and they replaced the mechanical portion of the door lock as well, which was sticking.

Maybe that’s what caused the battery to run down because the lock had too much friction? So now we’re getting closer to a type two problem here, but any problem can be looked at through multiple lenses. We troubleshoot it first. Maybe they found the root cause of why the mechanical assembly was misaligned or improperly installed. We’re still not sure that’s the root cause, to be honest with you, but it didn’t seem to work the next period.

They have apps where you can check into your room without a keycard now. That may be a better way of going for a future-state solution, but it still doesn’t solve the battery problem or the misalignment of a mechanical thing on the door.

It’s a good type three. The million-dollar question is, and I don’t have the answer, but what’s the type-four solution for this? How can I get into my room, 100 percent reliably — facial recognition, bio-scan, a lock that always works?

Q: Solar power lock or something.

Art: We don’t have the type-four solution figured out for this yet, but maybe there’s something better, magnets instead of mechanical locks. I don’t know, but that’s my point. You can take any problem, any one problem if you want, and look at it through four lenses.

Problem Framing Skills

Improve your ability to break down problems into their specific, actionable parts.