The way we think about problems matters. If we fear them, we tend to hide them. If we approach them all the same way, we may overanalyze simple problems (no analysis paralysis, please – just do it!) or jump to conclusions when faced with wicked problems that call for stopping, taking a deep breath, and figuring out what is going on before leaping to action.

Art Smalley’s new book Four Types of Problems can help us better understand the need for different approaches for different problem situations. Born of problem solving classification used by many problem solvers at Toyota in Japan (where Art worked many years ago), a casual summary of Four Types could be:

- Troubleshooting: reacting rapidly (and sometimes temporarily) to fix problems by quickly returning conditions to immediately known standards or normal conditions.

- Gap-from-standard problem solving: solving problems at root cause relative to existing standards or conditions.

- Target-state problem solving: removing obstacles toward achieving a well-defined vision or new standards or conditions (aka kaizen or continuous improvement).

- Open-ended problem solving: pursuit of a vision or ideal condition (think new products, processes, services, or systems).

The first two are both “caused” problems (s*** happens) and the second two are “created” (don’t wait for it to break – break it!).

Why bother categorizing any type of problem-solving at all? Simply because categorizing things can sometimes help. At a high level, there are living beings. But it helps to understand better what it means to be human when we have categories like mammals and sapiens to frame discussion and biological research. Shades of gray are all grey (sic), but they are also all colors.

We’d like to be able to paint in more than one color on more than one type of surface, and we’d like to be effective in dealing with any problem situation that may come our way. In order to better conceptualize the need for different approaches for different problem situations and therefore develop better capability in handling different situations, Toyota problem solvers in Japan sometimes tap into a framework that is similar to Art’s four types of problemsframework.

Of course, as individuals or as organizations, we all have our strengths and weaknesses. The most important contribution of Art’s Four Types categorization may be that it provides a self-reflection framework to assess and understand the state of our organizations’ problem-solving capability. Does your team have capability in all four types? Probably not. None of us are as proficient as we’d like to be in every situation. Your team may be very strong in the skills required to perform well in one or two of the types of problem situations and quite weak in the other two. Solid skills across the board will enable you and your team to flourish no matter the kinds of problems that present themselves to you.

For those of you paying attention to the Four Types framework as it relates to Toyota’s more broadly knownways of portraying approaches to problem solving, you will note that Troubleshooting and Gap-from-Standard are a further divide of the company’s “caused problems” category, while Target Condition and Open-ended further breakdown the “created” category of problems.

The caused vs created distinction is critical and yet often overlooked. We encounter problems that are:“caused,” where something breaks due to something that has gone wrong and we need to return things to a defined standard or expectation;or “created,” which is where we intentionally break the standard to set a new target condition or desired level of performance. That Toyota approach is well known by now as TBP, Toyota Business Practice; Tracey and Ernie Richardson do a great job of describing and teaching it (check out the book The Toyota Engagement Equation).

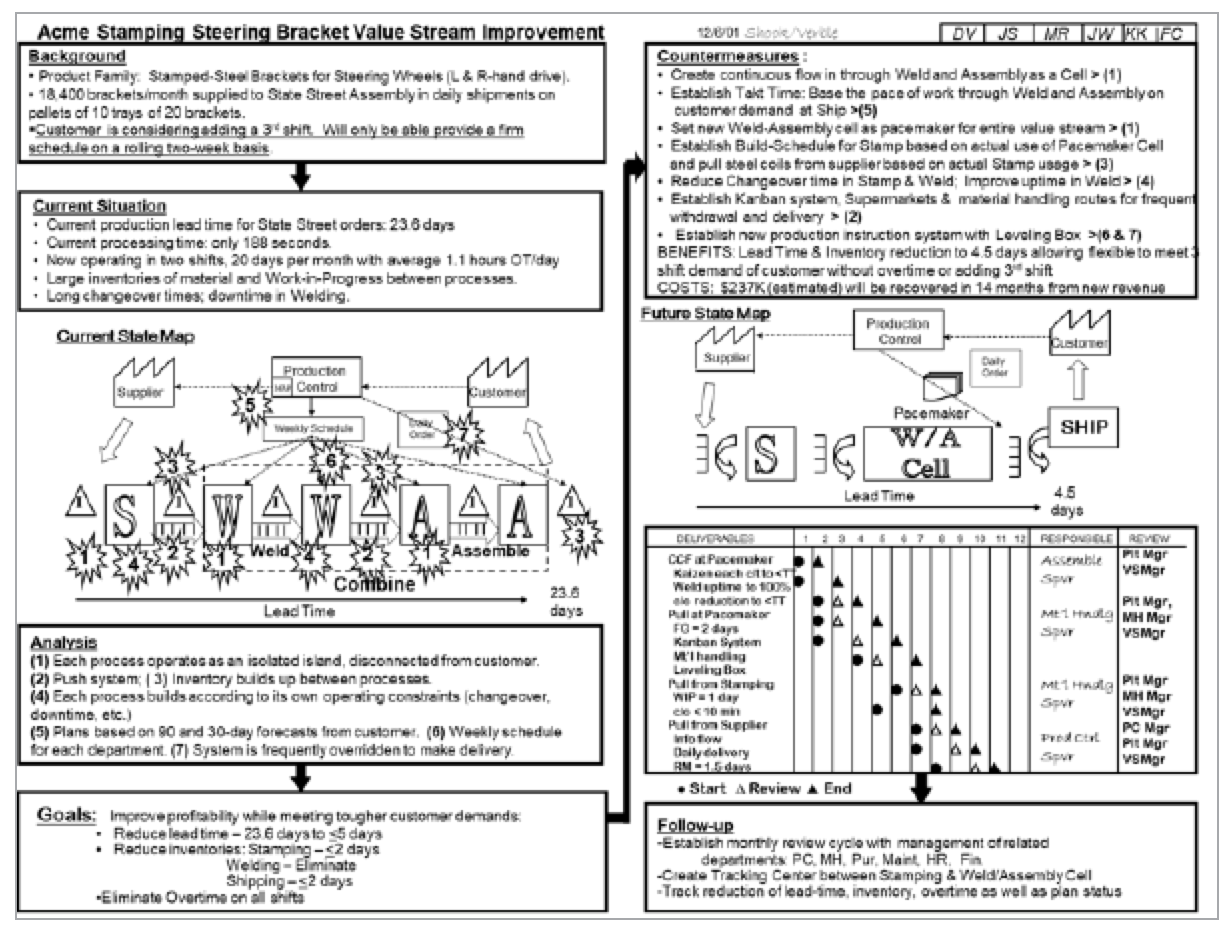

Art’s Type One and Two problems are a further subdivision of “caused” problems, while Types Three and Four represent deeper categorizations of “created” ones. The fundamental difference between Types Three and Four is that in Type Three situations, we have enough knowledge to draw a clear picture of the target condition and, if not a clear path, ofhow to problem-solve our way to get there (you can find plenty of excellent examples from improvement kata work or any good Future State VSM:

With “open-ended” (or as I like to call it “emergent”) problem solving, we don’t know enough about the desired state to even define it in detail, much less lay out a clear glide path of how to reach it. In the extreme, world hunger is the proverbial example. Or consider how Alexander Fleming discovered penicillin – he wasn’t even trying to solve the problem of infectious diseases. In that case, Fleming wasn’t working back from the problem to solve at all – yet a powerful solution to an important human problem emerged.

Closer to home, automobile companies are now flailing about, trying many different ideas to see what may stick (what solution may emerge) as new technologies and societal needs bring disruption to an industry that has experienced no fundamental structural changes for a full 100 years. Uncertainty and disruption are now pounding the auto industry from five directions: alternative powertrains, autonomous driving, asset sharing, intelligent vehicles and roads, and, last but not least, customers who may no longer desire 700 horsepower muscle cars or opulent luxury sedans.

Tesla, for its part, has its own clear vision of the future, albeit one which may turn out to be entirely wrong. Toyota, on the other hand, is running multiple parallel experiments. In my view, that’s a wise course of action when uncertainty is at such a high level. In the meantime, new players such as Rivian and Dyson are emerging alongside very different actors such as Waymo and Uber to further the disruption. In the face of this level of uncertainty, it can be a big mistake to try to test one single solution or even multiple hypotheses, a valid scientific method but one that can place unintended blinders on the experimenter.

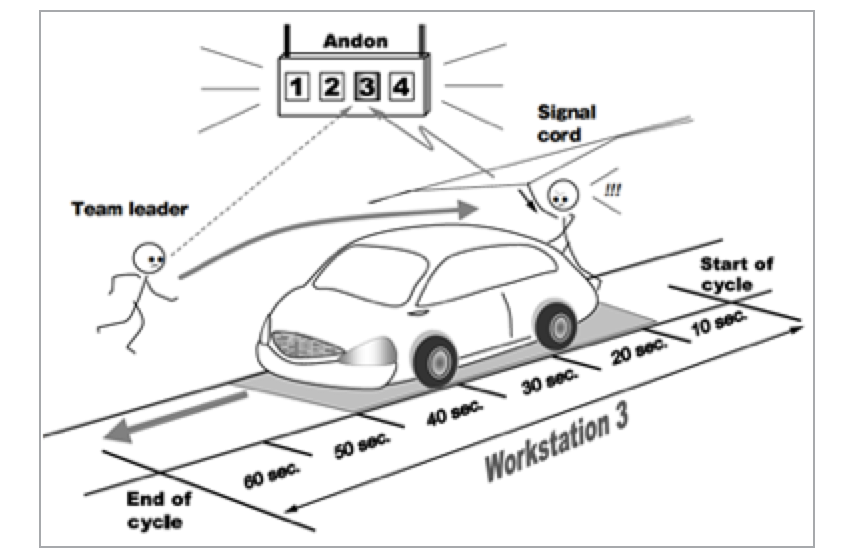

Type Four problem-solving entails and even expects innovation, But, importantly, innovations can occur in Types One through Three situations, too. Effective Type One problem solving shouldn’t be dismissed as merely applying Band-Aids. Toyota’s Jidoka principle and practices enable extraordinary levels of operational stability and provide a foundation for Type Two root cause analysis when called for. The distinction between the two (Type One and Type Two) situations is clear and critical to keep things moving and apply problem solving effort at the right time in the right way. And, from there, Type Three target condition situations can be tackled with higher degrees of confidence and reliability.

This illustration of Toyota’s famous “stop-the-line” andon system depicts a carefully designed process to enable effective type one problem solving, but the development of the system itself was a type three effort! With a target condition of enabling flow yet containing any problem or defect, the fixed-position line stop system engages each worker in identifying and responding to each problem as it occurs. Despite hundred and even thousands of andon calls each day – with problems responded to one by one – overall flow is interrupted only a few minutes per shift.

It’s vital that in order to do so organizations must recognize the need to be free from the fear of acknowledging problems, and the need to create the conditions where each individual feels comfortable finding and tackling problems.

What we’re really talking about here is creating adaptive capacity, the deep capability of an organization to tackle anything that comes its way, any obstacle that comes between you and where you want to go. Problems are never truly “solved” forever; having solved one problem or resolved the challenges of one situation, the newly created condition will bring its own problems or set of issues. Problems are not resolved with “solutions” per se, but “countermeasures,” a nod to the fact that even apparent solutions inevitably create new problems, something our friend Steve Spear calls “temporary responses to specific problems that will serve until a better approach is found or conditions change.”

Tackling them one by one is what gives an organization capability for deep adaptability. Indeed, rather than problem solving, we could well call this entire practice “problem tackling.” It’s vital that in order to do so organizations must recognize the need to be free from the fear of acknowledging problems, and the need to create the conditions where each individual feels comfortable finding and tackling problems. Harvard Business School’s Amy Edmonson spoke recently here at LEI about the compelling findings of her research on workplace psychology safety: Check out her new book The Fearless Organization.

As for Lean Thinking and Practice, whether you start with the Lean Transformation Framework or with Toyota and its approaches to establishing an enterprise of lasting excellence or with Thomas Edison and his structured process of invention or Galileo’s revolutionary approach to science or Steve Jobs’ approach to innovating products that customers love, problem solving (or tackling!) is right there in the middle.

Don’t do slow thinking when you should do fast, don’t do fast thinking when you should do slow.

Steve Spear

Steve Spear’s HBR article “DNA of the Toyota Production System” established lean thinking squarely within the long history of scientific methods of humans making things better for humans). Of late, Steve emphasizes the need to have different approaches to different problem situations. Recognize problems immediately and swarm to them when they occur. But, also, prepare proactively for future problems – which may be difficult to see or anticipate, especially system problems with multiple causes in play – before they happen.

If Daniel Kahneman’s thesis is correct or at least useful (I don’t know if it’s correct, but I think it’s very useful – check out his hugely influential book Thinking Fast and Slow), then we need different thinking and different approaches for different situations (no analysis paralysis AND no jumping to conclusions!). As Steve succinctly put it to a public audience at LEI earlier this year (LEI offers occasional public lecture sessions):

“Don’t do slow thinking when you should do fast, don’t do fast thinking when you should do slow…” – Steve Spear in a public address at LEI, Winter 2018

Problem Framing Skills

Improve your ability to break down problems into their specific, actionable parts.