Dear Gemba Coach,

I’m an entrepreneur and I used to micromanage everything, quite successfully. Now the firm has grown and I’m trying to delegate. How do I stop myself from cutting in when the actions my department heads want to take are plain silly, or not very creative?

Who says you should? But, yes, telling people that they should do as they think best and then correcting them when they’re on the cusp of taking action can’t be good for their motivation, or yours – nor for how fully they then commit to whatever is decided.

Consider:

- You can’t ignore adults’ experiences and worldview.

- We love new toys and they motivate our reasoning.

- We’re mostly overconfident in our own judgment.

- We want to succeed on our terms, not yours.

All this to say that people quite naturally see things in their own ways, jump to conclusions, commit to them, often in public and then would rather fail than back down. People are people. Clearly, if you correct them once they’ve committed to a path of action, they will quite naturally feel frustrated, fight back and/or implement your override with ill-will and in the narrowest way possible. When it fails, it’s on you, and they were right all along.

Does that mean that you should let your direct reports get on with doing stuff you don’t believe will bring value to the business? Absolutely not. Your judgment is equally valid (and, let’s face it, as flawed) as theirs. You must jump in, but by the time they have a solution in sight, it’s too late.

Intervene Upstream

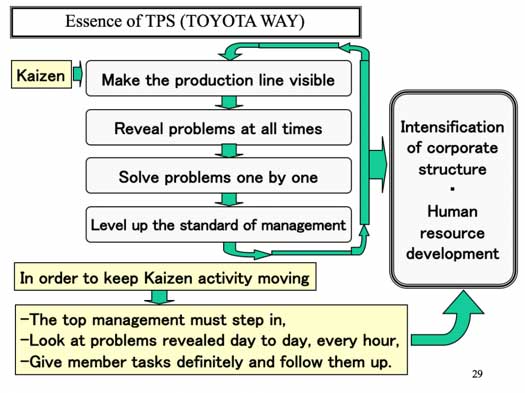

Here is the lean management model, as expressed by my father’s sensei, Mr. Hayashi from Toyota:

The trick is to discuss before solutions are formed by working on problems. Indeed, you can’t both want people to be autonomous in the way they run their area, and then challenge them on specific decisions without them feeling aggrieved. Actually, you can, and you might have to, but every instance is damaging to the trust relationship and the autonomy of the person.

The place to intervene is upstream, in getting agreement on how the problem is defined and what kind of solutions are looked for. My father taught me again and again to look for typical problems and typical solutions:

- Observe and discuss how the problem is framed: What is the problem we’re trying to solve and what kind of outcome do we seek?

- Discuss what is a successful solution and what is not: Simply responding to the situation is not enough – what would make it a successful resolution as opposed to a botched one?

Now, the deeper question of management is what do people do when you’re not there? You can’t be on their backs to check on every problem if you want to develop their autonomy. Therefore, you need to create a space for these conversations to happen. The three main ways this is done in lean are:

- Visualize the work environment: Make daily work visible through materializing processes with kanban and performance analysis boards and so on to create an environment where it’s easy to ask questions about specific details you think are problems and that your teams are ignoring. In this, you step in, and ask people to look more deeply into stuff.

- Kaizen activities: Within kaizen activities, teams will be asked to study more deeply how they do this or that in order to seek performance improvement activities. This is a great moment to discuss with them their understanding of the overall goals and how we try to achieve better outcomes.

- Obeya rooms: Dedicate a special room where customer’s opinions, goals, plans, problems, and planned changes are posted on walls that support an on-going discussion with teams and their management about the direction for improvement rather than the destination.

Of course, a conversation needs participation on both ends. This type of management requires a commitment from the people managed in the PDCA process:

|

PDCA |

Commitment from subordinate |

|

Plan: Prepare the change considered by clarifying

|

Declare your intent before you commit to a full-blown solution. This requires a commitment to expressing intent, rather than place your manager and teams in front of a done deal and then defend it. |

|

Do: Try it locally in a concrete way by finding:

|

Try before jumping to full-scale solutions and arguing that its the only way we’ll see an effect. This means committing to experiments to better understand the problem rather than rash moves to make the problem go away. |

|

Check: Figure out while the change is happening whether this has the anticipated effect:

|

To accept being challenged and question about how the experiment is going and to openly discuss outcomes and surprises. |

|

Act: To adopt, adjust or abandon the change and draw the right conclusions:

|

To not be married to one’s action just because one done it – which is hard. To accept taking a step back and asking the big question of what are we learning, not about making the change, but about better understanding the original problem? |

Careful: not all managers thrive in such an environment. I was yesterday on the gemba in a construction site where a young manager was struggling in a difficult project. To be fair, he was doing an OK job, and the situation was tough. But the point is that he was floundering. His CEO tried to help him by pointing out other ways he could address his problems and the young man kept repeating: “I’m doing the job, what more do you want? First give me additional resources and I’ll do it better.” The deeper point is about whether people see themselves as:

- Hired to get a job done: They need to administrate well the resources at their command to get the output out – anything else is out of their scope.

- Hired to succeed at the job and grow with the company: Understanding that showing “results” is not enough and that one is expected to committing to a learning curve in the job.

On another site of the same company, another project manager discussed openly and with genuine interest:

- What skill he thought he had learned.

- What was the next thing he needed to learn.

- How he intended to go about it to learn it.

- How management could support him in doing so.

Yes, why can’t lean guys ever give a straightforward answer? Back to your original question — there is a lean way of delegating without abdicating, but it means changing your angle of view on three important points:

- Hiring or promoting people to succeed, not just to get the job done, which means hiring or promoting people who are spontaneously interested in learning and agree to be coached along a learning curve, to be discussed with their manager.

- Discussing problems, not solutions: In order to let people be truly autonomous, discussions will happen around problems you’ve spotted and feel you should challenge your people with, on the occasion of kaizen activities, or by discussing your own larger, company-wide challenges and how people feel their efforts fit into solving those.

- Not hesitating to step in when you think something is not being handled right, but understanding every time you do so is a failure of the two preceding steps.

Your question can be answered by another question: how can you lead your managers to discuss their intent before they push their solutions forward? The power of plan-do-check-act is opening up the thinking in our heads and laying it bear for all to see so that deep discussions can occur at the level of assumptions, not conclusions, and so you can support your people’s autonomy in taking decisions because discussions about good or bad judgments are happening upstream