Behind a dust barrier of orange plastic sheeting, workers with power tools disassemble the metal superstructure and chutes of a huge mechanical parcel sorting machine in the middle of Canada Post’s Calgary plant. But the real demolition work here is being done by lean thinking.

Calgary Mail Processing Plant at a Glance

- Built in 1975

- 350,000 sq. ft.

- 430 employees on three shifts daily and weekends

- Processes 425 million pieces of mail annually

- One of two mechanized processing plants in Alberta

The sorter, which required 58,000 square feet, eight operators, and a maze of conveyors to separate and route incoming parcels to their destinations, has been replaced by a nearby cell occupying just 12,000 square feet, staffed by six people sorting parcels manually, based on lean principles of takt time, flow, and balanced work. When the sorter is gone, the cell will move to a far edge of the sorter’s former space, bringing parcel sorting operations much closer to a dock where trucks deliver and load parcels and mail. The move will cut lead time and eliminate the need for much of the conveyor system, which will mean lower maintenance costs and fewer back injuries to employees who had to clear jammed parcels from conveyors and chutes.

These and other improvements at Calgary and companywide at Canada Post show how lean principles can move beyond their traditional ambit of repetitive manufacturing companies.

A Closer Look

Like many services, postal operations look a lot different from traditional manufacturing. Manufacturing customers order finished goods from a plant, which orders raw materials from suppliers. In a postal service, paying customers are suppliers, pushing raw materials — mail — to plants, often with end customers not knowing that mail is coming – or even wanting it. So at first glance, there appeared to be few — if any — opportunities to use lean techniques such as finished goods supermarkets, or leveled production. And since the “inventory” of mail already is paid for, moving it faster doesn’t improve cash flow as in a traditional lean implementation.

But beginning in the mid-1990s officials at Canada Post began taking a closer look at their operations as part of a drive to cut costs and improve service. At the time, mail was moved in big batches from one production island, such as a sorter or other large machine, to the next machine, where it often waited and then was processed as fast as possible.

They discovered that such batch-and-queue postal operations had many of the wastes that lean production principles were designed to identify and eliminate from manufacturing. For example, letters and parcels, like parts, waited to be transported and processed. Large batches of mail, just like large batches of goods, required excess space, equipment, and handling. (Moving mail faster doesn’t improve cash flow, but it does reduce the number of containers, forklifts, and conveyers needed.) Postal activities, like their manufacturing counterparts, contained wasted motion. Long changeovers on highly automated equipment increased lead times. Missorted letters or parcels were equivalent to defects and rework. And while tools like supermarkets might not make sense in the postal environment, flow did. In fact, they discovered that flow and most lean principles applied to the post office’s main mission of moving the mail.

“I used to think that we weren’t a manufacturing company; we didn’t produce anything,” said Don McLellan, director, mail operations, at the Calgary facility, “but you can lean out mail operations. What we’re looking for is flow; in one door and out another.”

“What’s interesting about our business is that pull system supermarkets don’t apply so much,” said Carli Sanderson, manager projects, at Calgary. “We look more at flow because we have no control over what comes in at any point in time.” Flow between processes is maintained by FIFO (first-in, first-out) lanes.

Calgary improvement teams pursued continuous flow in much the same way that any plant — or office for that matter — would. First, they identified product family value streams. They found four:

- Letters

- Parcels

- Express mail

- Publications and advertising mail (“Pubs and ad mail,” as it is called, includes items such as magazines, catalogs, and marketing pieces.)

“Each value stream has had success with applying lean,” said McLellan. Here’s a look at how it was done in pubs and ad mail.

Sweating the Details

About two years ago, an improvement team of managers and engineers believed a manual sorting cell could be designed to perform better and faster than the existing system in which mail bags in large metal containers or “cages” were removed from trucks, staged on the dock, and ultimately emptied through holes in the floor onto hidden conveyors. “The conveyors held all the product so you never saw your inventory,” said McLellen.

The conveyors took the bags to the sorting machine, which was a much smaller version of the one described above for parcels. Operators at the sorter read the coded destination tags on bags and keyed them into the computer system, which routed the bags by conveyor to a big cart. Carts were taken to another area of the plant for further sorting to the final destination. “We handled the bags four times,” said McLellen. Beside being wasteful, multiple handling meant operators were repeatedly lifting the 50-to-60 pound bags.

The team used value-stream mapping and other tools to study the mail moving through the sorter and discovered it could be broken into four major groups based on its general destinations: eastern Canada, southern Alberta, the city of Calgary, and mixed mail that had to be sorted further. “Each of the four flows worked out to being almost exactly 25% of the volume,” said Sanderson.

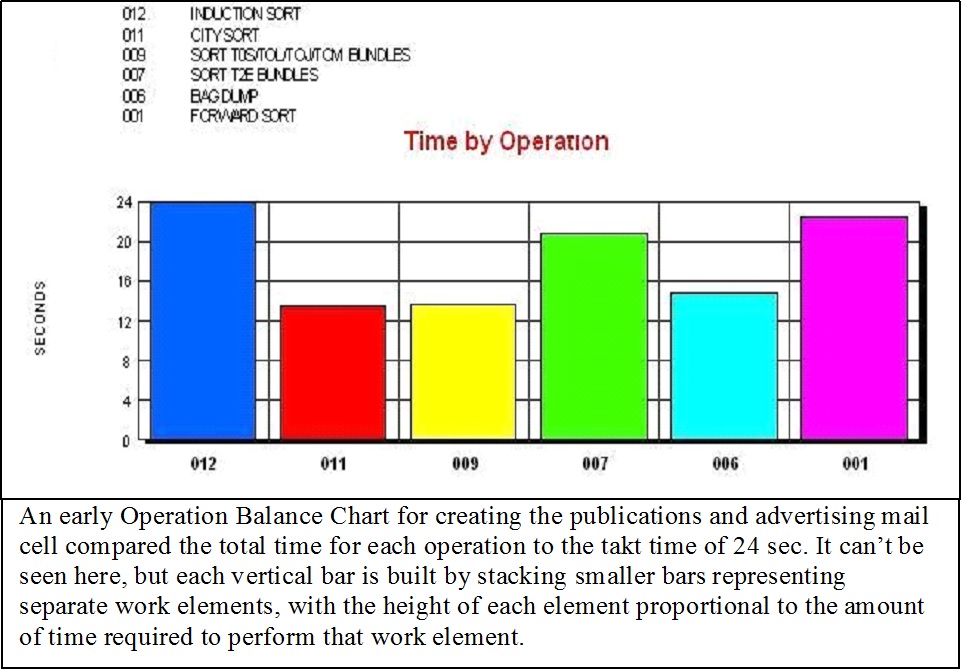

Next the team members calculated a takt time, the heartbeat of any lean system because it matches the rate of production to demand. They divided the amount of time in seconds on one shift, minus nonworking time, by customer demand, defined as the normal volume of mail bags per day coming through the process.

“We came up with one bag every 24 seconds,” said Sanderson. “If the volumes went up, all we had to do was run the cell longer. We had two more shifts to play with.”

The next step was to identify and time the actual work elements performed by operators. This helped the team separate elements that added value from those that didn’t – such as walking — and eliminate the nonvalue-adding activities. Team members observed and timed operators lifting bags, reading destination tags, opening bags, dumping out the bundles of mail, reading addresses, tossing bundles of mail into containers, etc. Once the work elements and times were known, the team created an operator balance chart to staff the cell and distribute the work based on takt time.

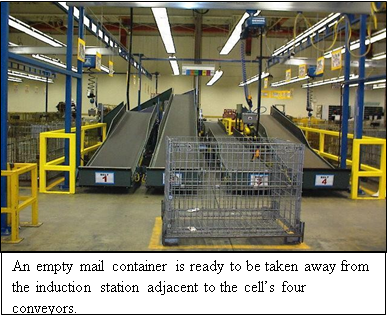

In the new cell, metal cages containing mail bags are lined up in FIFO order in staging lanes across from the first operation, called “induction.” Lanes are sized to hold approximately two hours of work. “Now the inventory is right in front of your eyes, not on hidden conveyors,” McLellan said. “When the work is visual, you know exactly what you have. You can plan your day. The supervisors know how to staff better because at the beginning of a shift, they know how much work is there and how many people are needed for an area.”

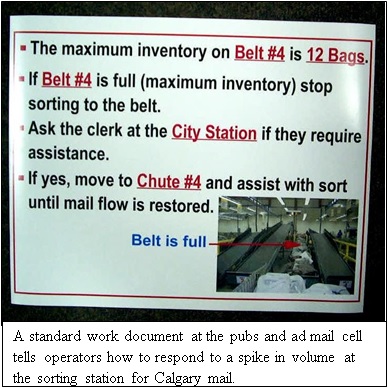

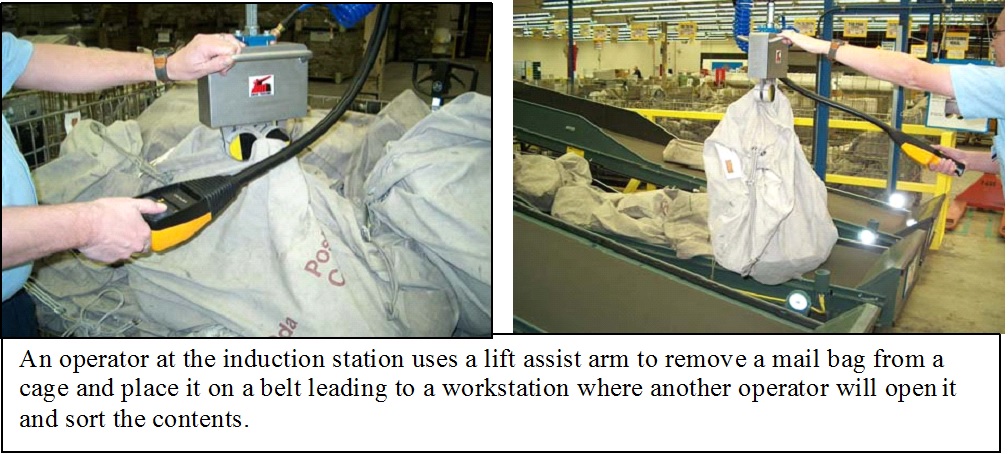

Every 24 seconds, the operator at the induction station removes a bag from a cage placed in a painted square adjacent to the belts. Using a new overhead robotic arm that eliminates bending and heavy lifting, the operator removes the bag, reads the destination tag and places it on one of four short conveyor belts, corresponding to each of the four major mail flows. The conveyors move bags to nearby stations where operators open them and immediately sort the mail. Operators can move from one station to another to help clear a spike in mail volume.

Before the cell went live, the team constructed a mock-up off the plant floor where operators could try out the new process, get a feel for the pace of work, and offer suggestions. The team also developed standard work documents for each station that describe the major steps, including key points and safety tips. McLellan said the involvement and new robotic arm helped employees adjust to the cell. “I thought we’d get some pushback but we didn’t.”

Sharing the expectation for the pace of work in the new cell turned out to be a valuable exercise, he said. In the unionized postal environment, managers worried about setting expectations for how much mail the cell should sort in a given amount of time. But the pace and visibility of the cell proved to be a benefit because employees as well as supervisors liked knowing what was expected and whether they were ahead or behind. In fact, operators had to learn that in the new system faster wasn’t always better.

“At first, they thought they had to go as fast as possible to get mail into the cell,” said McLellan. “We explained that if you put a bag into the cell every 24 seconds, the mail goes through faster and it saves us money. If you put a bag on every five seconds it plugs up the system.”

|

Box Score for Publications and Advertising Mail Cell |

||

|

|

Previous State |

Current State |

|

Space Used |

17,000 sq. ft. |

9,500 sq. ft. |

|

Operators |

10-15 |

6-7 |

|

Productivity |

19 bags/hr. |

25 bags/hr. |

|

Lead Time |

2.03 days |

.98 days |

|

Process Control |

None |

Container pitch of 6 per hr. |

|

Bag Travel Distance |

2,294 ft. |

1,580 ft. |

|

Bags double handled |

46% |

11% |

|

Ergonomic assessment |

Medium risk |

Low risk |

|

Processing publications and advertising mail improved with the introduction of a lean cell to replace a mechanical sorter. |

||

Automation Advantages

Lean thinking also helped to unplug the jams in Calgary’s highly automated systems in the value stream for letters. The first step in the process use machines that automatically cancel the stamps and orient the letters face up so the next machines in the process can read addresses, apply bar codes, and sort letters for shipment to destinations. Letters for Calgary remain in the plant for a final machine sort to carrier routes.

Traditionally, the hoppers feeding letters to machines at the first step were kept filled.

An improvement team discovered that introducing smaller batches of mail more often led to fewer jams. So now a bag is dumped into the hopper every 35 seconds. The team also found that the machine could run faster and smoother if operators culled out large envelopes and sorted them separately. “A group of people got together and came up with these ideas,” said McLellan. “We said, Okay let’s trust it because lean is working for us.” The result is that letters arriving in the afternoon are sorted by 11 p.m. that night instead of 3 a.m. the next day.

Getting away from big batches is paying off at the final step where Calgary letters are sorted by route. The sorting machine reads bar codes applied in the previous step and deposits letters in small bins, each corresponding to a carrier’s route. Calgary has roughly 1,800 routes, but the machines has only 180 bins, so 10 “plans” or programs are needed to sort the city’s letters. After each program ran, operator performed the equivalent of a changeover. They would “sweep’ or clear the bins and load the next program. Loading a program was a computerized process that took just two minutes. But sweeping took 45 minutes, during which time the machine was idle.

“We used to run 30,000 or 40,000 pieces of mail in a plan, thinking that it was best to process a big batch to minimize the number of changeovers,” explained McLellan. “But you couldn’t run more mail until the bins were empty or you’d mix up routes.”

By switching to smaller batches of letters and adjusting the programs to use half the bins, an improvement team boosted performance. Now, while the sorter runs a program that’s been adjusted to use 90 bins at one end of the machine, an operator sweeps letters from the 90 bins at the other end. Programs were redesigned to put two routes instead of one in each of the 90 bins. An operator keeps them separate by inserting colored plastic cards between the stack of letters for each route. The result is that the machine can run constantly, matching the throughput speed of 30,000 letters per hour of the previous sorting machine and reducing the inventory between steps.

“If you run 10,000 or 15,000 pieces of mail at a time it never fills up,” McLellan said. “And we now have no lost time due to changeovers.”

Value-Stream Managers

Moving from a mindset of batching to flow required training. Four years ago, Calgary trained all its supervisors in the basics of lean and value-stream mapping. “Black belts,” including Sanderson, received extensive training in lean and six sigma. Explaining the difference in applying each, she said that if a sorting machine develops a high reject rate that inhibits flow, she applies six sigma tools to identify and eliminate the cause. Value- stream managers also have basic knowledge of mapping and lean so they can work with the black belts to redesign and improve value streams.

“Value stream managers focus on the end-to-end process, from the pick-up to the delivery of their value-stream products,” McLellan explained. “It’s improved our service dramatically.”

When he arrived at Calgary in 1999 as day shift manager, McLellan and the two other shift managers were responsible for all the products on their shifts. A year-and-a-half later, the plant switched to value-stream managers responsible for their product families across all three shifts. As operations director, McLellen added a new wrinkle by sending the managers outside the Calgary plant on visits to local postmasters.

“They had to go out and visit the small towns where their products went,” he said. “They had to talk to the postmasters where we were failing miserably, watch their products arriving, and find out why we were failing. So, they really got end-to-end responsibility from induction at Calgary to where the mail is delivered.”

Such exercises led directly to improvements at Calgary. Local postmasters knew mail was arriving missorted, but couldn’t tell why. When the value-stream managers saw the problem, they knew where it came from because they were familiar with the processes at the plant.

“We had to jump our continuous improvement effort up a notch,” said McLellan. “We never would have done it if we hadn’t sent the value-stream managers out to take a look.”

Calgary is trying to extend the other end of the value stream, working with its big customers, the major mailers in Calgary. The city has the largest number of corporate headquarters in Canada after Toronto. Big customers are supposed to notify the plant when they are preparing a large mailing, such as bills to customers. Postal workers will pick up the mail in stages beginning earlier in the day to smooth the volume moving through the plant instead of having it arrive all at once.

Because Calgary is a growing city, thanks to the oil boom and a favorable tax structure, “our mail volumes are constantly growing,” McLellan explained. “We had to deal with that pressure and we didn’t have a system to flow the mail through until we began implementing lean. Now we have something that works for us.” McLellan estimates Calgary is adding 18,000 addresses annually.

That kind of growth puts pressure on Calgary’s 12 satellite postal facilities, called “depots” where mail carries are based. “We were adding so many routes that these buildings were at maximum capacity and we were going to have to build more.”

The Calgary plant has freed so much space – a total of 61,000 square feet so far, that Canada Post will move mail carrier operations into the freed space, and shrink from 12 small satellite offices to four larger ones. “So our operating maintenance costs will diminish, transportation costs will be cut, too, along with lease costs,” said McLellan. The challenge is to keep up with the growth while continuously improving by cutting costs, he said.

Steven Withers, director, logistics and processing improvement, at Canada Post said the effort is paying off companywide since Tom Charlton, the company’s retired senior vice- president of operations, became interested in the postal applications of lean in 1995.

Improvements, despite declining volumes nationwide due to email, include:

- 3.2 million square feet of space freed-up for consolidation, reducing reliance on leases

- 10 years of consecutive profitability

- Returned dividends to the Canadian government each year, including $59 million in 2005

- Reduced reliance on material handling equipment, overhead conveyors, forklifts, etc.

- Dramatically reduced on-floor inventories, reducing lead time, and improving quality

- Freed-up capacity and an increase in available machine time

- Improved labor relations –no labor disruptions since starting lean (The company said no one would lost their employment because of lean.)

Withers believes the company is at a new stage in its transformation. “We’ve left the phase of just making improvements in isolated pockets, and we’re beginning to plan initiatives to improve companywide performance,” he explained. “In other words, value- stream plans and hoshin kanri guide our initiatives, rather than isolated improvements.

We are also on the verge of seeing lean become an embedded philosophy that will continue uninterrupted when the key champions leave or retire.”

For More Information

Canada Post’s vision is to be a world leader in providing innovative physical and electronic delivery solutions, creating value for customers, employees, and all Canadians. In FY 2004, Canada Post Corporation had net income of $147 million on revenue of $6.7 billion. It processed 10.9 billion pieces during the 12-month period.