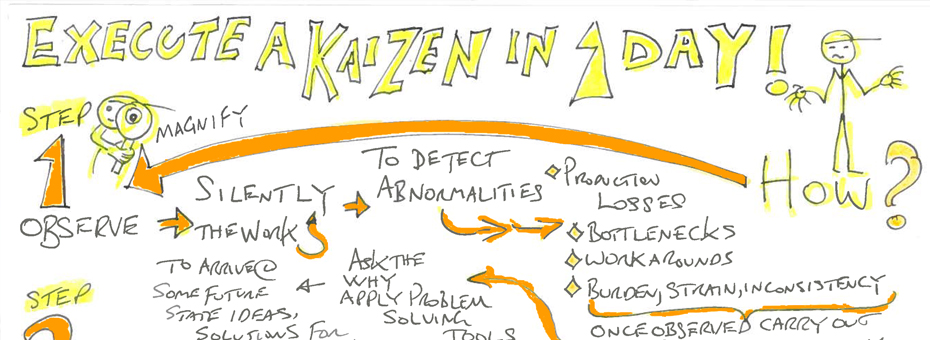

Often when I hear people talk about kaizen, they are under the impression that this is some huge event with dozens of people fixing loads of things over a week. Yes, those sorts of events do happen (Toyota calls them jishuken), but for me the world of kaizen has always been about fixing the little things that hinder production – things that steal seconds, minutes and hours of production time over a long period – and fixing the problems that create burden, inconsistency and strain for the team member doing the job.

For me, the secret to kaizen is making incremental improvements stacked up to a big gain over time. That’s why I am a big believer in doing the “limited scope” one-day kaizen activity within an 8-hour shift window.

The purpose here is to save seconds and minutes in production and reduce the potential for burden, inconsistency and strain. This has worked and is often allowed by operational management as you are not putting them out of action for days – only hours, or a shift; maybe two at a push.

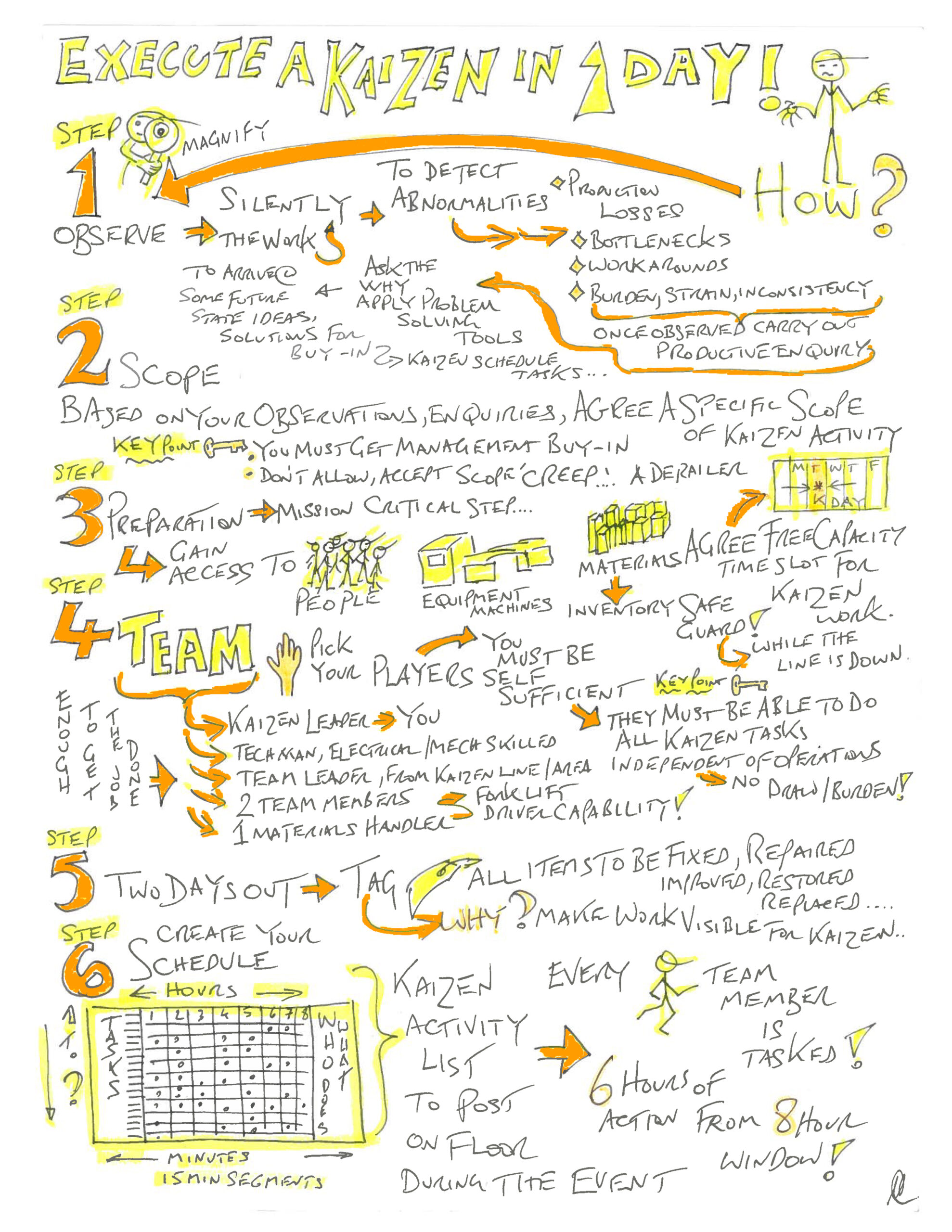

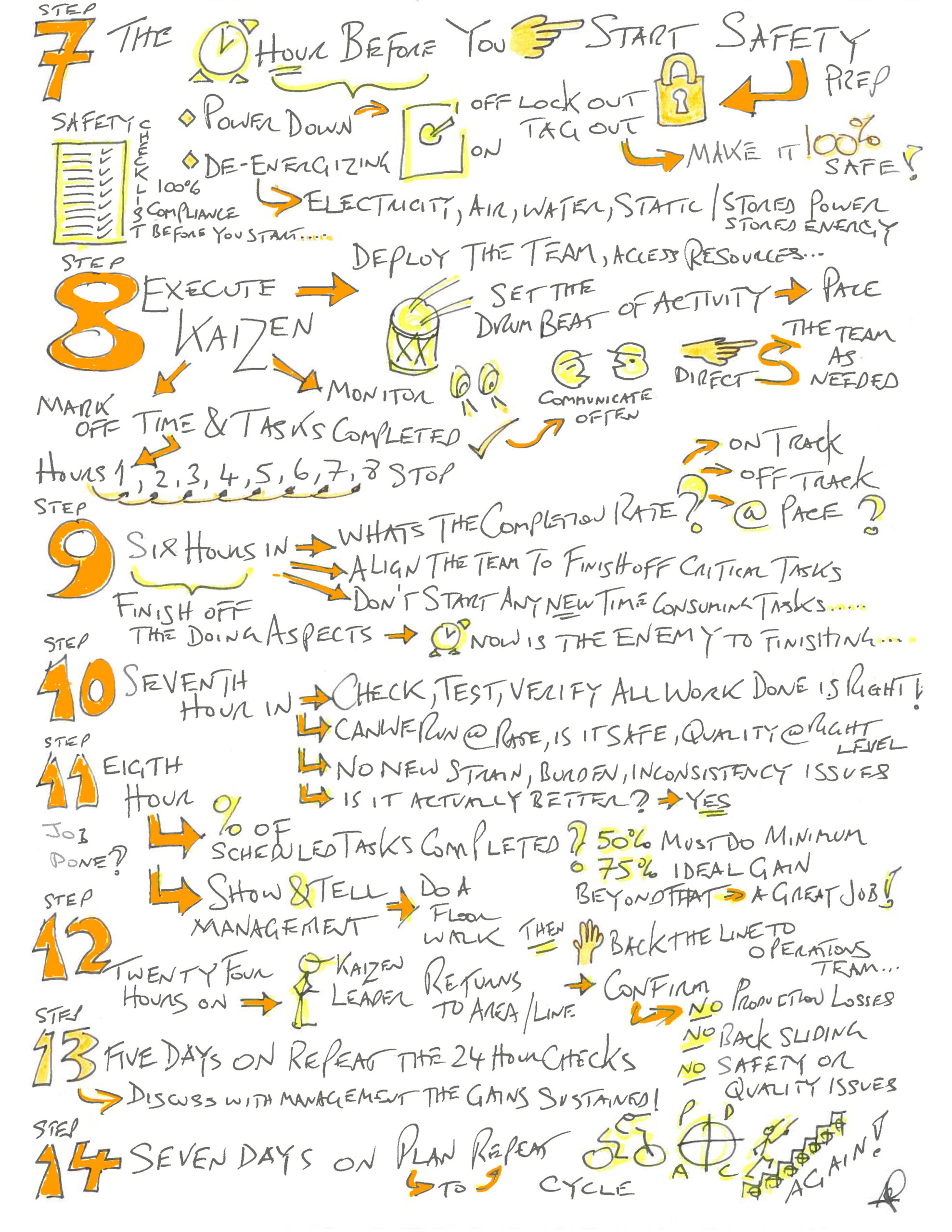

This, as I depict in my sketches and the animation, does work if executed properly, and provided that you don’t bite off more than you can handle. Agree with the stakeholders on a very specific scope of work – you do this, no more, no less, and you will leave the area and equipment in a better state that it was before.

I can’t stress enough that preparation is key to success – doing this on the fly will fail and you will backslide. And by extension, backsliding will also undermine the value of kaizen in your people’s eyes. Don’t rubbish your reputation and that of our lean principles by not doing your homework and planning for success. I know this is more easily said, but I have lived all I am talking about, learning from my mistakes, and I am passing on my experiences so you don’t have to endure the pains….only gains.

Are you going to give it a try? Learning by doing is the only training.