(The following article is adapted from Dan Jones’s comments in his recent podcast appearance.)

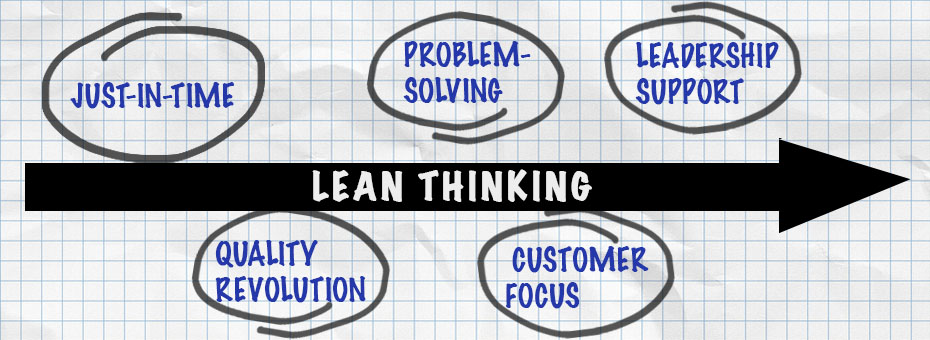

The current pandemic serves as an opportunity for us to rethink the world of enterprise (and more). And as we reflect on how the world will be different once Covid-19 passes, it’s worthwhile to put the evolution of lean thinking into perspective. I would argue that we’ve been through five different revolutions in our understanding of lean, with more to follow.

The first one focused on just-in-time: examining time, understanding the need for speed, and recognizing the efficiency improvements that come from focusing on doing everything quickly for customers when they need it – value streams, flow and pull. While separating that idea out from the obvious need to have safety stock somewhere in case of big unforeseen calamities if you can and responding quickly if you can’t. I believe that running the business in a just-in-time fashion is widely accepted now.

The second was a quality revolution, Toyota style rather than the Six Sigma approach. You can’t actually run an interdependent, integrated system involving lots of actors doing lots of different things, unless everybody performs to the highest level of quality and reliability and on time – Jidoka and standard Work. You can’t achieve just-in-time unless you engage everybody, every day, in continuous improvement and Kaizen problem solving—so that the uptime of every single step in the process is really, really high. In fact the true impact of this quality revolution was to enable big systems to be integrated for the first time, rather than run as a series of discrete units.

That brought about the third revolution in problem-solving: if we’re engaging people in problem-solving, we have to give them a framework for learning how to problem-solve in teams and understand how to do that within the context of the needs of the enterprise. That was the learning revolution – a management system focused on capability building.

The next step, having engaged everyone in improvement, is thinking back from the customer: rethinking the business and rethinking the product, using the insights from the engagement in the current process, and the improvements to the current products and services.

And finally, if you’re going to have a focus on the customer, and on learning and building capabilities, you need leadership that can support this learning, as opposed to leadership that just decides on a plan and hands it over to somebody else to implement. Leaders define the gaps to be closed, create a dialogue to debate proposals to close them, discover and remove the obstacles to implementing them; and support learning and capability building in doing so.

I think the singular contribution of our recent book The Lean Strategy was its argument about a very different approach to decision-making: the switch from a traditional top-down approach, separating decision-making from implementation. This is a radically different mindset, and we call it a 4F framework, which is all about: finding the next things the organization needs to do better, facing up to the inadequacies of the current system or the challenges for the future and measuring those and focusing on those and then, framing those challenges for all the teams in the business to come up with proposals for projects to improve them. Finally, out of all of that experimentation, you form new solutions. These are the thought processes that underpin the leadership revolution. This 4F decision making is amplified into a strategic framework for leaders in the brilliant new book Learning to Scale by Regis Medina.

I believe that in the end we’re still going through the journey to discover the true potential of the lean journey, and the true potential of lean as a business system. I think that these five revolutions come together as a lean business system, and one that is in tune with the rapidly changing circumstances of our time. It is a business system focused on addressing these new challenges, not just one that makes businesses in a fairly stable environment more efficient. So it’s about building an organization that mobilizes all of the resources and all of the people in the business to affect change.

Virtual Lean Learning Experience (VLX)

A continuing education service offering the latest in lean leadership and management.