Be among the first to get the latest insights from LEI’s Lean Product and Process Development (LPPD) thought leaders and practitioners. Subscribe to The Design Brief, LEI’s newsletter devoted to improving organizations’ innovation capability. Subscribe now.

It’s still surprising when people want to debate whether an individual’s activity is waste in product development. “You know,” they say, “a developer’s work is not like manufacturing.” Really? “That’s so interesting” is my typical response while thinking about missing the forest for the trees.

The fact is that the amount of waste in most product and process development systems is staggering — and almost none of it has anything to do with the work of individual contributors. Most of the waste in development is the direct result of a poorly designed development system and processes that seem intent on thwarting even the most talented development teams.

I am usually more comfortable talking about value creation in development. It’s more fun, and, after all, creating new value is the point. Unfortunately, most development systems create more frustration than value. They waste people’s valuable time, not to mention copious amounts of organizational resources. Consequently, I think it’s essential that we also discuss opportunities to reduce some of that system-generated waste — starting with badly designed development processes. Fortunately, the countermeasure to this problem lies in fundamental lean thinking: Make the value-creating steps of product and process development flow.

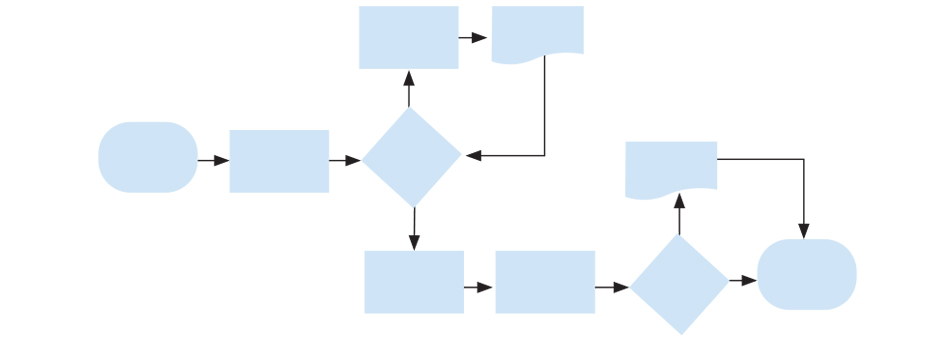

Still, one significant challenge is creating flow when people from across the organization are contributing (or should be) to a new product’s creation. For example, achieving flow might require coordinating the concurrent work of design, engineering, software development, manufacturing, and logistics. And that can seem a daunting task. The key is synchronizing the individual contributing workstreams, and that starts with deeply understanding the actual work. By identifying the interdependencies of critical inputs and outputs across workstreams and understanding the impact of critical decisions, you can keep the process moving steadily forward instead of constantly looping back for expensive rework.

There are two mutually reinforcing approaches to creating flow in development: Building flow into the process at the start and helping your team synchronize work in real time.

Building flow into the process ensures the development team makes the most of incomplete but stable information and enables concurrency. To build flow into the process, first design the development tasks and their sequence to maximize the utility of vital inputs and outputs. Then determine milestones and schedule integration events when teams can coordinate and evaluate progress based on agreed-upon quality-of-event criteria. To help this evaluation, be sure to use input requirements as leading indicators of progress. Value stream and decision mapping are often reasonable ways to start your development process re-design.

Building flow into the process ensures the development team makes the most of incomplete but stable information and enables concurrency.

Unfortunately, no process, no matter how well designed, will be sufficient. Organizing and leading your development team to synchronize work in real time during development helps the team respond to inevitable unexpected situations. As Mike Tyson says, “everyone has a plan until they get punched in the face.” Stuff happens. Things go wrong. Teams need to be able to react and keep making progress in the face of unexpected changes. Effective obeya stand-up meetings and good visual management are very helpful here, and a strong chief engineer leading the program is essential. Depending on the product, you may want to consider organizing cross-functional teams around product sub-systems.

The point is that you need tools and mechanisms that give the team an early heads-up and enable them to absorb inevitable variation and keep moving forward.

In this month’s video, we have excellent examples of both approaches. First, Peter Cooper, platform leader, Medium Wheel Loaders, at Caterpillar, explains how they used value-stream mapping to dramatically reduce waste and create better flow on a set of time-critical development programs. Then Alison Seward, program senior director at GE Appliances, a Haier company, shares her secrets for synching up work across her large development team on a critical new product program.

See the Lean Posts and related ebooks detailing other guiding principles:

Designing the Future

An Introduction to Lean Product and Process Development.