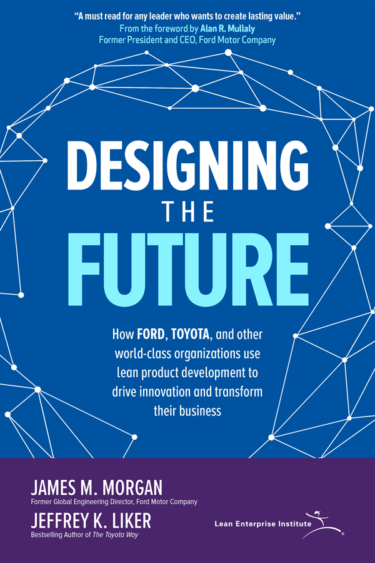

Book

Designing the Future

Today’s elite companies know that the ability to consistently create successful new products and services is their most powerful competitive advantage. In addition to providing…

View book$24.00

Senior Advisors and Staff

John Shook

John Shook learned about lean management while working for Toyota for 11 years in Japan and the U.S., helping it transfer production, engineering, and management…

Learn more

Board of Directors

James (Jim) Womack, PhD

Widely considered the father of the lean movement, Womack has been talking and publishing about creating value through continuous innovation around deep customer understanding for…

Learn more

Board of Directors

Peter Ward

A professor emeritus of Operations Management, holding the Richard M. Ross Emeritus Chair in Management at Ohio State University’s Fisher College of Business, Ward frequently participates in…

Learn more

Board of Directors

José R. Ferro, PhD

By founding Lean Institute Brasil in 1999 to disseminate the principles and practices of lean thinking to Brazilian companies, Ferro helped catalyze a global movement to establish…

Learn more

Senior Advisors and Staff

Tom Ehrenfeld

Tom Ehrenfeld is a writer and editor living in Cambridge, MA. A former writer/editor with Inc. Magazine and Harvard Business Review, he is the author of The Startup Garden: How Growing A…

Learn more

Faculty

Karen Gaudet

Karen has over 30 years of experience leading, training, and developing the capability of team members and executives in rapid-growth environments. Most recently, she’s coached…

Learn more

Senior Advisors and Staff

Masia Goodman

Masia Goodman leads online learning at the Lean Enterprise Institute (LEI), with an extensive background with learners across all age groups. Her foray into education…

Learn more

Board of Directors

Josh Howell

Joshua Howell is president and executive team leader at the Lean Enterprise Institute (LEI). For over a decade, he has supported individuals and organizations with…

Learn more

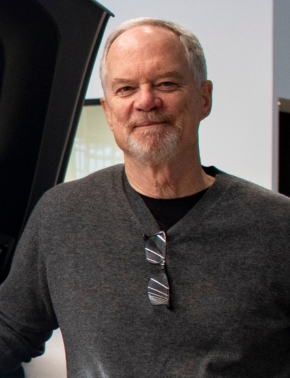

Senior Advisors and Staff

Jim Morgan

Jim is a senior advisor at Lean Enterprise Institute and a board member at Adrian Steel. He has a unique blend of industry leadership experience…

Learn more

Faculty

Alice Lee

Continuous improvement leader and coach. Her responsibilities include: Lee served as vice president and special assistant to the president for business transformation at Beth Israel Deaconess…

Learn more

Inactive Staff

Chet Marchwinski

Chet has been a humble, unwashed scribe of the lean continuous improvement movement since books by Taiichi Ohno and Shigeo Shingo first hit North America in the…

Learn more

Senior Advisors and Staff

Lory Moniz

Lory Moniz is a relative newcomer to Lean despite her remarkable ability to think and communicate visually, which she’s noticed has propelled her career. In…

Learn more

Faculty

Mark Reich

During his extensive career, Mark has led lean transformations and coached executives in various companies and business sectors. Clients include GE Appliances and Ingersoll Rand…

Learn more

Senior Advisors and Staff

Matthew Savas

Matt serves as content director at the Lean Enterprise Institute responsible for the institute’s content strategy in all mediums. He previously served as Director of…

Learn more

Faculty

Katie Anderson

An internationally recognized leadership and learning coach, consultant, and speaker, Katie is best known for inspiring individuals and organizations to lead with intention and increase…

Learn more

Faculty

Lara Anderson

Lara Anderson is a trainer and coach supporting organizations of all sizes to improve their operations and develop their people so they can deliver more…

Learn more

Faculty

Katrina Appell, PhD

With over 15 years of coaching, facilitating, training, and team development experience, Katrina is passionate about supporting organizations in lean transformation. She has coached lean…

Learn more

Faculty

Jim Benson

A pioneer in applying Lean and Kanban to knowledge work, Jim is the creator of Personal Kanban and co-author of Personal Kanban: Mapping Work | Navigating…

Learn more

Faculty

Derek Browning

Derek Browning is director, Consulting Services, for LeanCor Supply Chain Group, where he directs a portfolio of projects. His experience includes over 14 years working in logistics and supply chain,…

Learn more