Editor’s Note: This Lean Post is an updated version of an article published on January 23, 2019. It is the third in a three-part series focused on the importance of people development in creating and sustaining a lean enterprise. The series explores the theme through three critical dimensions: leadership, coaching, and training. This piece delves into coaching. Read the first and second parts in the series.

Recently, I was involved in a discussion with some great lean thinkers who specialize in lean coaching. It was a valuable and insightful discussion that resulted in the creation of a fundamental definition of lean coaching. Here is the definition we all agreed to:

Lean coaching is creating conditions for learning and developing capabilities with lean thinking and practice for the achievement of organizational purpose. It is rooted in the Gemba with Plan-Do-Check-Act (PDCA) at its core. It demonstrates respect through challenge.

Of course, this definition incorporates key elements of lean thinking and practice. Lean Coaching must allow the learner to find their own pathway, it must connect to a key business need, and it must nurture capability for the learner to continually improve and evolve his or her own development path.

After that discussion, I contemplated what we had discussed and felt that it really came up one step short. It did not factor in the amount of lead time to transform the learner. This is a fundamental part of lean done right (remember Just-In-Time?). Toyota revealed to us long ago that we must constantly reduce the lead time from order to cash. This produces a creative tension throughout the entire system. We should deliver to the customer just in time, produce just in time, and prepare our suppliers to do the same. This drives out the waste of excess inventory, movement of people and material, and challenges the capabilities of the system.

But it also puts great stress on capabilities of the organization (and the people in it) to continuously transform. It is challenging in every way.

So, as a coach for lean transformation, how can I apply this to my own work with organizations? One clear measurement is my lead time for transformation of the gemba, but also transformation of the people who do and manage the work.

Subtle questioning to nudge the learner in the right direction is one way. But what is its impact on lead time?

And what happens when an organization is under big pressure to transform where the risk is very high? What is the best approach to coaching?

While working in supplier development for Toyota, I learned another way: “challenge coaching”. I’m not talking about what we’ve often heard about – crazy Japanese guys yelling some vague question or direction to the team and storming out of the room. This is more careful and deliberate.

Let me share a specific example that I experienced while there. I was working with a team of two other people in a stamping company located near Lexington, Kentucky. The plant was generally in bad shape – nothing near a lean target condition. Long changeover times in presses, frequent missed deliveries to customers, absent shop floor management.

While we were working to transform the plant from a push to pull system, a huge, overriding problem revealed itself. After parts were stamped, they went through a paint process. That process was producing a nearly 20% defect rate. The defects were not thrown away – a completely disorganized process was set up to sand out all the blemishes coming from paint and have them re-painted.

However, the sanding process couldn’t keep up with the volume of defects being produced. So what did Karl (name changed), the Plant Manager do? He rented out a separate warehouse off-site to store and hold all the defects being produced. Wow!

We started to support problem-solving in the paint booth to understand where the defects were coming from. But, this situation persisted for about a month until one day while TSSC was on-site, the CEO showed up. He started to ask questions about all the rework and the inventory. One question led to another and he learned about the off-site warehouse. It wasn’t pretty. He told the Plant Manager that if he didn’t close that warehouse in a month, he better start job hunting.

Tough, huh? I knew this CEO – he was a great man. He loved his people and his people loved him. He had dedicated over 30 years of his life to this small business. But on this day at this time, he used that tactic.

The next day Karl turned to TSSC and said ,“Can you help?” Now this is a guy who had basically ignored us for a couple months. I said, “Sure, but it requires one thing.” Karl asked: “what”?

“I want you to stand in that paint booth the next three days and watch the process.” Write down everything you see happen. Watch how parts are placed on the racks, how they are sprayed, how the people do the work, what are the environmental conditions of the booth. Write it all down.”

The Plant Manager looked at me and looked around the room. “Well, I’m supposed to attend a meeting at corporate HQ in Atlanta tomorrow. Maybe I can watch when I get back. But I can get someone to do that.”

“You heard my request.” Then I got up and walked out of the room.

I heard nothing for two days while we continued to improve in the plant. I did some of my own observations in the paint booth.

Defects continued to accumulate, and the situation got worse. On our last day there, just before I was getting ready to leave, Karl came up to me. He’d just gotten back from his meeting in Atlanta. He said, “I’ve thought about our conversation. I can spend some time in the paint booth next Tuesday”.

“That’s not what I asked. You need to spend time there to learn. But you don’t know why. Here’s the deal. If you want us back, please send a record of what you observe over 3 days next week. I’ll take a look at that and decide if we will come back. Do you have any sense of urgency to tackle this problem? Do you think it’s someone else’s responsibility? Please think again.”

I went back home.

A week later, a report came. Detailed observations and inputs. From Karl. He had observed the paint booth and the surrounding area for three days. He’d gathered detailed information. He learned two key points from this observation. One, the sanding process to rework the paint blemishes was done by hand and, due to space in the factory, was not far from the paint process itself. This created dust in the air which caused even more potential contamination. So in fact the defects were causing more defects. Unbelievable. Furthermore, the protection between the paint area and the general manufacturing area was not adequate. And people entered and exited at will. And frequently. All this stuff seems straightforward, but when you are in the middle of a chaotic situation, it is not so easy to see problems clearly. But Karl was able to by standing and observing carefully.

I went back.

The Plant Manager greeted me at the front door. “I learned a lot. In fact, I learned more in three days than I have in the last three years. I have just never really stood and observed the process.”

The outcome – we spent time in that paint booth, I coached Karl through problem solving by sending him back again and again to do deeper observation of the process. Modifications to the painting process and the booth itself to protect it better from contaminants resulted in quickly reducing the defect rates. In two weeks, Karl closed the warehouse. Not shittin’ ya.

I learned a lot. In fact, I learned more in three days than I have in the last three years. I have just never really stood and observed the process.

Plant Manager

What if the CEO or I had just suggested in a gentle way that Karl investigate the problem? How long would defects have accumulated?

We say in TPS that we strive for zero defects. Because one defect means one customer somewhere is getting a bad product. How do we reconcile this important drive for excellence with the time to develop capability to solve the problems that create defects? It is a constant battle, but bending the learning curve is critical.

Of course, we want people to “pull” for coaching, but sometimes people need a “push” to pull.

Challenge coaching has its place. Taiichi Ohno used it to transform Toyota. Is it right in every situation? I doubt it. What do you think?

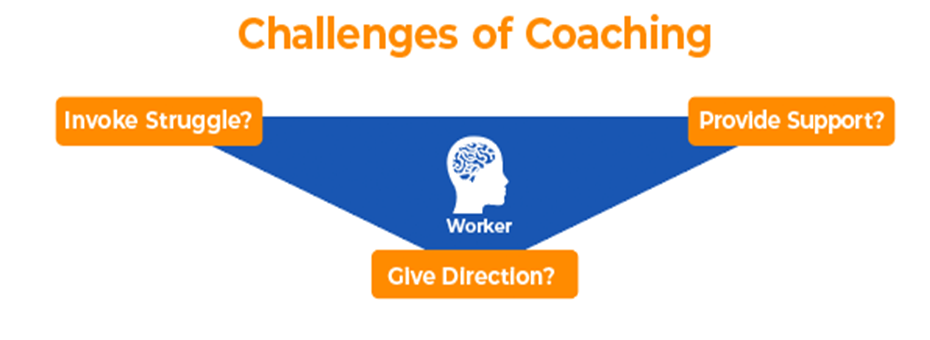

I often think about it terms of a triad of three options:

- Letting the Team Member work through the struggle to overcome the challenge

- Step in to support as required

- Be directive

There is a place for all three. There is no black and white answer – it depends on the criticality of the business situation, the level of the challenge, and the capability of the Team Member. The capability of the Manager/Coach to judge when to apply these issues can be learned I believe. While in Toyota, I was fortunate to be exposed to many people who were masters of this. Sometimes it was quite frustrating, but in the end it has been amazingly rewarding.

Karl came to me after this was over and shook my hand. He said that he didn’t necessarily like the learning in the moment, but the challenges he was faced with and the coaching he received were critical to changing his perspective. I still keep in touch with Karl (who as gone on to be a great coach of companies!) and to this day he attributes that moment in time and that coaching to a change in the way he looked at work.

Good enough for me.

Managing to Learn

An Introduction to A3 Leadership and Problem-Solving.