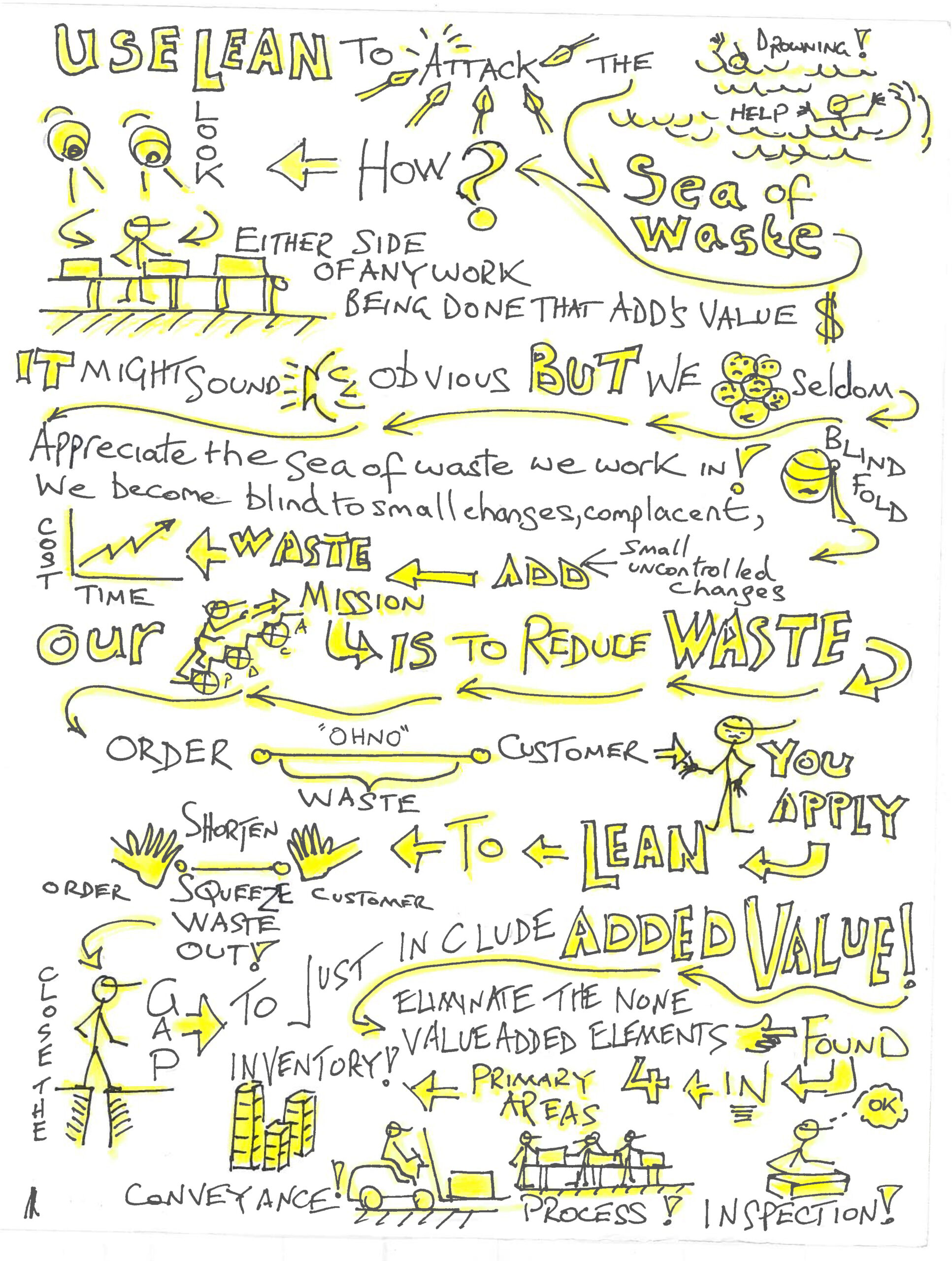

Eliminating waste is one of the most basic fundamentals of lean thinking. That’s why I’m always amazed by how many kaizen activities I see that have it wrong. Specifically, I tend to see a lot of kaizen activities that focus strictly on eliminating process waste, and nothing else.

Eliminating waste is one of the most basic fundamentals of lean thinking. That’s why I’m always amazed by how many kaizen activities I see that have it wrong. Specifically, I tend to see a lot of kaizen activities that focus strictly on eliminating process waste, and nothing else.

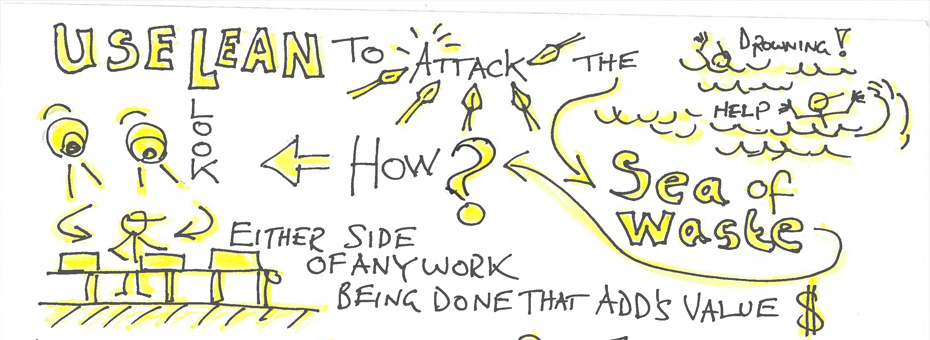

To be fair, inefficient processes are indeed a major cause of waste. But there’s more to it than that. Look at your entire value stream. Look at what you really need to make to satisfy the customer (inventory), from where to where the product really needs to move (conveyance), and whether any non value-adding inspection activities are present (inspection). How else can the inspection or check be done without having to devote a person’s time? There is so much opportunity in these areas we ignore, and we ignore these often and just attack the process instead. Why?

You can get far more out of kaizen activities by expanding their focus into those three additional areas. I also recommend focusing on all of them, not just the obvious one that suffered as a consequence of the other three not being really investigated, analyzed and improved. See my sketch to find out and explore more of what I am talking about.

Over the next few months I’ll be posting a series of sketches on identifying and addressing waste in each of the four areas. Hopefully they will help you think and then maybe act to revisit how you look at waste in your areas of work.